Please tell us what your tractor serial # is, and a pic would help.

Hi First Cat,

from memory the cam gear drives the mag. Its end float is set by a machined boss/pad on the inside face of the gear cover --right at the back of the main engine cylinder block/head-- and the end face of the camshaft on the outer side and the inner face of the cam gear and the cyl. block--pad must be worn excessively--likely caused from worn bearing/shaft of the intermediate gear mount, exerting thrust to the cam shaft/gear.

You will need to remove the pony to do any work on this area. The lube oil for this gear train is from the pony clutch housing. This gear train is separate from the pony crankcase oil so if the seal at the pinion shaft is shot then these gears run dry and wear greatly.

Spec. normal end clearance is 0.007"-0.015" with a max. of 0.025"

Cheers,

Eddie B.

Eddie B thanks I have a D6 9U 3405. I will have to take some pictures. It seems that the shaft that the gear is connected to has moved back into the motor. I can take the retaining pin off the shaft and slide the gear forward to it's proper location but without the shaft. That's why I was asking how to access it. The gear just does engage the (cam gear?). Are there any manuals that show in more detail how the pony motors come apart. I just have the Cat Parts Book.

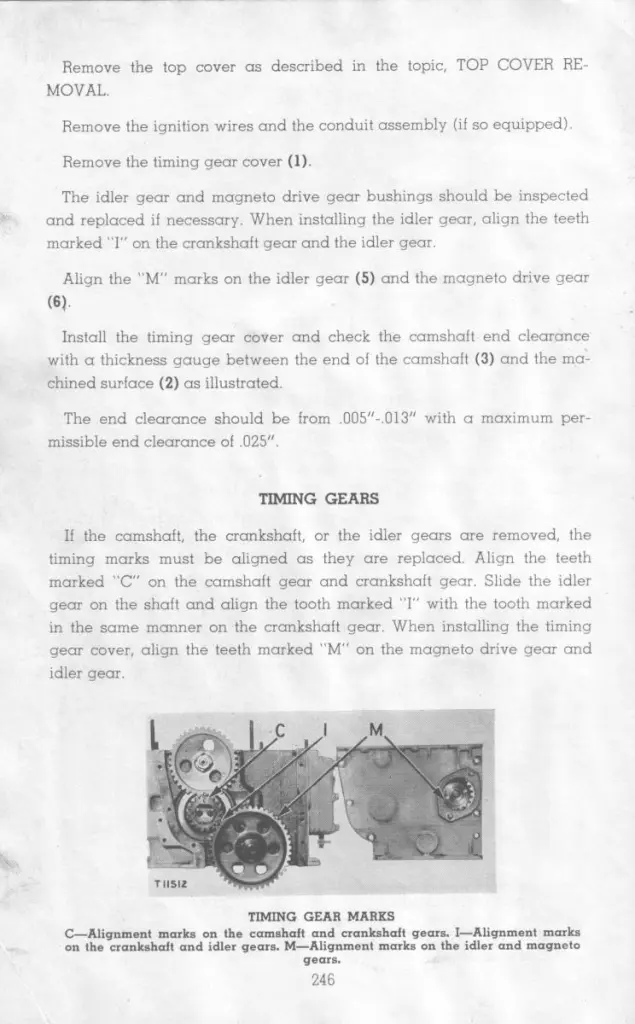

The 9U mag drive is a different deal. The mag drive gear runs on it's own stub shaft and is driven by the idler gear. Both could be shimed to give the alignment you need.

This is what happens when people do not give ALL the details.

Should have included #'s for Cat sorry. Old Magnet can this be accessed without taking the pony off? If so what is the process? What kind of shims. This forum and all the help and information is a great resource.

Thanks

If it's just the mag drive gear that is the problem you can access it with the mag removed. If you need access to the idle gear the pony will need to be removed to take off the timing gear cover. Spacer washers/shims will have to be selected for the required thickness and diameters. Might start with machinery bushings/washers from McMaster or make your own.

Also need to determine why there was so much wear in the first place....wrong mag coupling?, wrong mag? etc.

Thanks for the reply. Everything had been working fine and then one day went to start and had no spark. The mag has been on the Cat since I bought 4 years ago. We removed mag to have it checked and when we re installed heard a loud pop, could we have pushed the gear and shaft back when tightening the bolts holding the mag because it could have been miss aligned with the mag coupling? Does the shaft that the mag gear attaches to just pull out after gear is removed?

The shaft is held into the gear cover by a tapered pin so it is fixed and should not push in or out without removing the cover first and then the pin.

Be sure to retime the "M" marks on the mag drive gear and the idler gear it meshes.

Alas, my old steam driven computer is down and I cannot do scans with my old steam driven scanner and this newfangled laptop--will keep trying. I can post saved scans but do not have any for this topic.

Cheers,

Eddie B.