"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

is the spark nice and blue or is it yellow. i was told they only like the factory points gap. but try increasing the plug gap slightly say 28thou instead of 25. also clean and lighty file dress (if needed) the mating surfaces for the mag and clean the plug seat area rub a little 2b graphite pencil on them it will help with the return path giving better spark. a old mechanic showed me and it does work hell it might just put off that mag rebuild a bit longer.

Humm good question.... Looking... at firs glance I'm thinking so but let me look later tonight..

Get a resistance reading on the coil secondary, should read approximately 6200 ohms.

Yes, coils are interchangeable.

thanks for all the great info. I will let you know what I find. I will say I never thought to check the spark plug gag.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

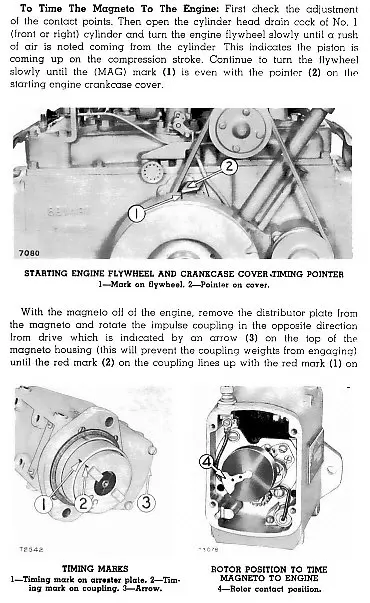

after I got my head out of the clouds and got things timed right well I hope. I did not find the MAG marking on the pony flywheel at first only the TDC mark and had timed it to TDC and not MAG. the pony motor running for about 45 seconds -1 minute then died. so checking things I could see it sparking out inside the mag. so I pulled the coil back out and you can see where it been leaking spark out the front. after changing it out for another coil from a parts mag I now have a good spark that will jump 3/8 when you trip the impulse. it starts and will idle low nicely but is rich and will not rev up when I try to rev it up it pops and backfires. it still is very rich as I see black smoke from the exhaust. I went through the carb last weekend in the drilling out the brass plugs and making sure everything was clean with a pipe cleaner. but still runs very rich. I think I still have a timing problem and not a fuel. when I had the pony running last year it would not turn much more than 1/2 max rpm but was able to get the main fired off with a little summer in a can. I can roll over the pony flywheel and hear the impulse fire when TDC comes up to the top each time for both cylinders. I could try moving the timing gear a tooth the two M's will never meet up when turning 44 teeth and an 18 to re time all the timing gears I will have to pull the pony to get the side plate off. one side not is the pointer is missing off this pony motor so I was using eye reference to where it should be from some of my other ponys and what the serviceman reference shows in pics. I know this maybe doesn't make much sense and should be simple and straight forwards but this welder playing mechanic needs help.