Hello woodie, has your carb ever acted right or did this just start? It sounds to me like you may have a passage ( or several) plugged. Since these carbs are cast iron the passages can rust shut or partially shut and cause problems. Soaking them in carb cleaner is no use because it won't touch the rust. The only real way to do it right is to drill out the little plugs(carefully) and ream out the passages. Then you can thread the holes and plug them with a removable plug for the next time.

This is is what I had to do for my D7, also an 8800 engine.

Best of luck.

Bruce P

Hello woodie, has your carb ever acted right or did this just start? It sounds to me like you may have a passage ( or several) plugged. Since these carbs are cast iron the passages can rust shut or partially shut and cause problems. Soaking them in carb cleaner is no use because it won't touch the rust. The only real way to do it right is to drill out the little plugs(carefully) and ream out the passages. Then you can thread the holes and plug them with a removable plug for the next time.

This is is what I had to do for my D7, also an 8800 engine.

Best of luck.

Bruce P

[QUOTE=Bruce P;138462]Hello woodie, has your carb ever acted right or did this just start? It sounds to me like you may have a passage ( or several) plugged. Since these carbs are cast iron the passages can rust shut or partially shut and cause problems. Soaking them in carb cleaner is no use because it won't touch the rust. The only real way to do it right is to drill out the little plugs(carefully) and ream out the passages. Then you can thread the holes and plug them with a removable plug for the next time.

Thanks for the replies.I have disassembled the carb and cleaned and blew through all the passages I could see. Earlier, I'd cleaned the fuel tank and blew out the fuel line and shutoff valve and also coated the tank in hot weather and allowed it to season several weeks before filling it with gas. The fuel is good and clean in the glass bowl.

I was unable to get the thing started until yesterday when I tried it without pushing the choke rod in and it kept running without flooding so I just kept it running with the rod out. It ran good at idle until I finally gave up and shut the fuel valve and let it die. It also dies when I flip the little stop and allow it to go full speed (it runs much faster for a second but dies suddenly). The same when I move the compression lever up out of the Run position because it isn't running fast enough. When I took the carb apart the last time, I took it completely apart and also knocked the little plug out on the side of the carb. that has the vertical line on it and ran a lot of kerosene through all the passages it and blew it out good with my air hose. That jet not being pointed still has me puzzled and it may not have actually ran since I put the carb. back together last. Are there other passages to knock plugs out of other than the brass one that has the two notches facing the inside the throat? I put the plug back in with the line vertical, as it was when I knocked it out. This pony motor is the one on the side of the engine, not the type at the end of the engine.

Well as far as the main needle goes the one in my carb is blunt on the end and also has a hole in it. It looks weird but it works ok. Let's start with fuel flow, have you verified good flow from the tank to the carb? If so then is it getting into the carb without restriction, there is a screen at the carb inlet that could be stopped up. If all that checks out then I would look to plugged passages. The brass plug with the vertical line in it has the idle ports in it. The other plugs just plug off the passages after they were drilled at the factory.

I was surprised at how crapped up my passages were. I'll post some photos of the plugs I used later.

Bruce P

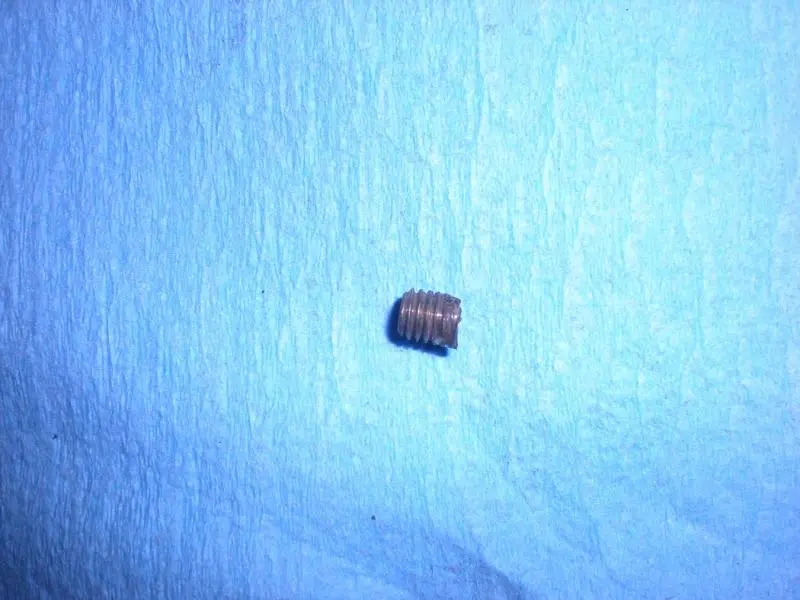

Here's some photos. The plugs I used are ones that go into various two cylinder john deere carbs (A, G, ect) the thread is 10-32 I think. The holes are already the right size you just have to tap them. At least that's how mine was.

After I went through all this mine still wouldn't idle without some choke. This drove me nuts. Finally I looked real close at the idle ports ( the ones in the brass plug) there is a large port and a small port. The large port needs to be BELOW the throttle plate. Mine was upside down, once it was in the right way, presto, good idle without choke.

[attachment=27196]DSCN4485.jpg[/attachment][attachment=27197]DSCN4482.jpg[/attachment][attachment=27198]DSCN4480.jpg[/attachment][attachment=27199]DSCN4484.jpg[/attachment]

I hope this is clear as mud.

Bruce P

check out this thread (Pony-rebuild-in-progress) If you do a search for it and look it over you will see how I drilled and re plugged all the passages. and took a bunch of photos to look at. It sounds like your not getting enough fuel I bet there is still some crud somewhere

Woodie, echoing Bruce's comments, that brass plug does need to be oriented correctly. Some advice is to align the "line" vertically, but I've found the better approach to be to ensure that the large notch is below the throttle plate, between the throttle and the intake manifold. This is so that with the throttle closed at low idle, the manifold vacuum can "get at" the notch in order to pull gas through it. If it's not set that way, then you need choke to idle. Also, the plug needs to be flush with the inner bore of the throttle body.

Second, that symptom of briefly speeding up then dying when you remove choke definitely sounds like a blockage to me. It's not enough to blow through the passages or even flush with fluid. You must use a drill bit in your fingers, with the drill bit just a little smaller diameter than the passage bore, and deliberately clean those passages out. The worst will be the passage across the carb bowl base, but don't neglect the others, even if they "seem" clean - do them anyway. Your main jet needle is correct with the blunt end with the hole in it. Further up the shaft of the needle should be a small hole that lets gas in, it then flows down the needle and out the end (at least that's how mine is set up).

Thanks for the suggestions. I will tear it back down and do some soaking and do and check everything suggested. Woodie

When I rebuilt the carb on my D8, several of the brass plugs were leaking air. Possibly, one or some of the plugs could be leaking outside air, so you may not be getting the proper internal air flows. Don't know, only an idea.