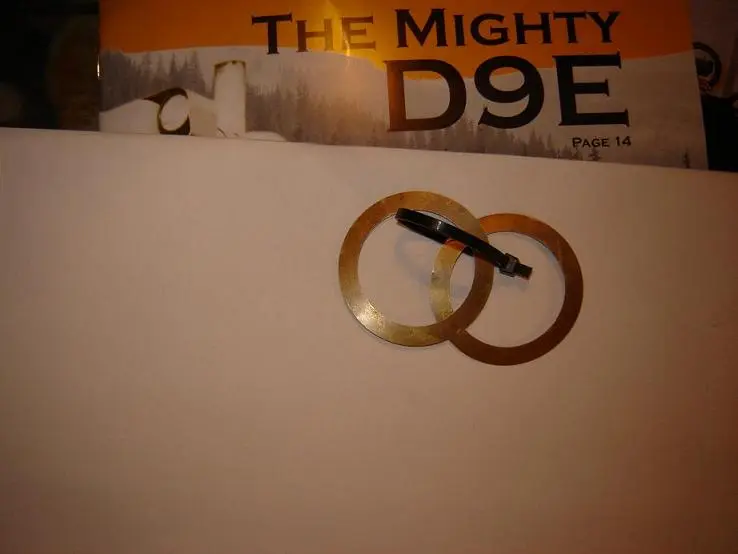

You got to be careful puting shims between moving and stationary parts. There's not much metal there. If they rub much at all they can heat up fast and then break up and pile up.

If you need to limit end play with shims, it's usually better to machine down one part or another, then machine a washer at least 0.060" thick to make the required clearance.

This is just general machining. As to cam end float on a pony motor, I have no idea what's acceptable. And are you sure you want to shim the cam outward? This modifies the lobe/tappet contact pattern. And what are you shimming to on the other end of the cam float? What are the chances that you will tear down after a dozen hours or so to see if you are doing damage to the shim or eventually to the engine?

I tend to be pretty careful with such modifications when I have to put them in and forget them.

Jack

You got to be careful puting shims between moving and stationary parts. There's not much metal there. If they rub much at all they can heat up fast and then break up and pile up.

If you need to limit end play with shims, it's usually better to machine down one part or another, then machine a washer at least 0.060" thick to make the required clearance.

This is just general machining. As to cam end float on a pony motor, I have no idea what's acceptable. And are you sure you want to shim the cam outward? This modifies the lobe/tappet contact pattern. And what are you shimming to on the other end of the cam float? What are the chances that you will tear down after a dozen hours or so to see if you are doing damage to the shim or eventually to the engine?

I tend to be pretty careful with such modifications when I have to put them in and forget them.

Jack