Cats Forever

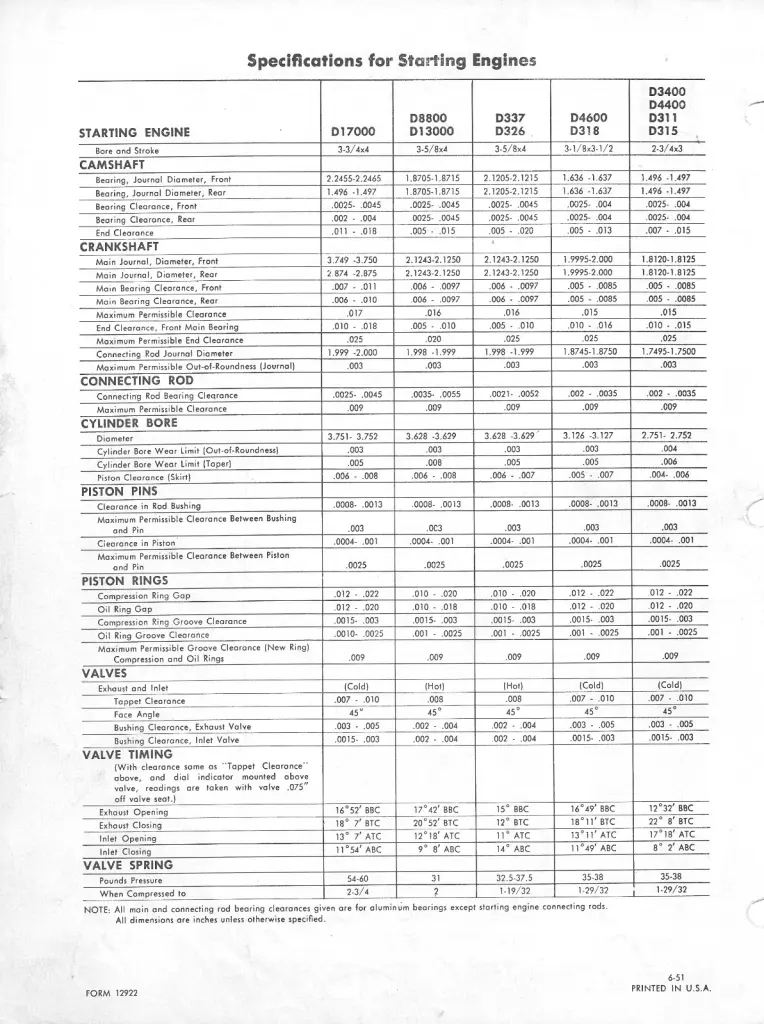

If you are talking about end play clearance on the crank, my -01 book says between .010 to .015 with a max of .025. Do you maybe mean main bearing or rod bearing clearance?

Big end = rod

Gudgeon = wrist pin

If it's in that book, it'll be correct - plenty of editing and checking over 80 years of that spec : )

Cats Forever

The -01 book says .005 to .0075 clearance new (same as Elton's -02) and worn out at .013 clearance crank journal to rod bearing.. Worked on the neighbors 6U when we rebuilt the pony and clearance was less than .010 after some 30 years of use. It's an ag tractor (1952) so we went back with std bearings and it runs great. Only thing is it is a rope start.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality