Hi raklet,

The oil clutch graders have a special 3 section oil pump as opposed to the usual 2 section used in other applications. The third section scavanges oil from the flywheel housing.

By what you describe you have normal scratches and grouves as seen from normal usage. These should not be detrimental to the full output of the pump sections as two sections are master clutch, one scavange oil, one for master clutch low pressure supply oil for cooling and lube, and only one section is full engine oil pressure as used in other applications, like the D6. Unless you need to utilise full clutch potential and abuse it it should survive on a little less than designed oil flow for these needs.

Some pix would be beneficial to help us help you.

Scan is from my MG SRM.

Cheers,

Eddie B.

Excellent advice from both. 👍 I will get some pics posted. Thanks.

Excellent advice from both. 👍 I will get some pics posted. Thanks.

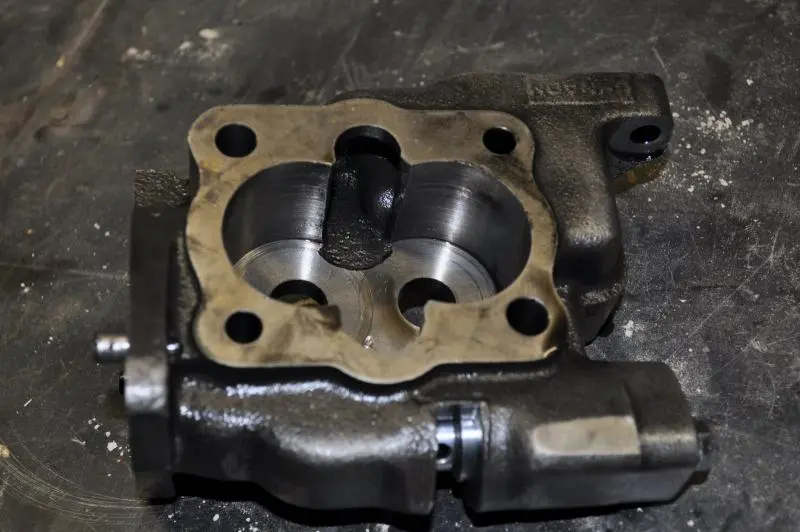

Here are some pics of the pump body and the gear.

Housing looks well worn....what do the clearances measure?

Hi Team,

yes, housing and gear have what I would term normal marks from foreign material passing thru, if there is no obvious wear step in the area of the gear cavity pictured then it should be OK, even then some wear is tolerable, 0.002-0.004". If you can determine if this is one of the scavange sections then it should be of little concern as the scavange sections only transfer low pressure oil from one area to the main sump or low pressure oil supply for the master clutch itself.

Even if it were the main pressure section I would only stone off the burrs from the gear teeth and end faces and the gear cavity and reuse as is, or, if you felt something needed to be done fit up a new set of bearings and go from there.

To me it looks useable, especially in view of the rarity/cost of parts and the likely low stress use of the unit in preservation/display purposes, for full load commercial production it may still be OK. These gear pumps are fairly forgiving of gunk damage to a point. If the rest of the engine -- bearings etc -- are in good condition it should make good oil pressure at op. temp.

Just some thoughts.

Cheers,

Eddie B.

I have a oil pump 4 section and each section have a part number on 7f3121-7f3123-7f3119-4f6025

and have a 3 section 7f7237-7f3119-4f6025

Clearances measure .003 with tight drag. I'll hang onto the pump for now. Thanks.