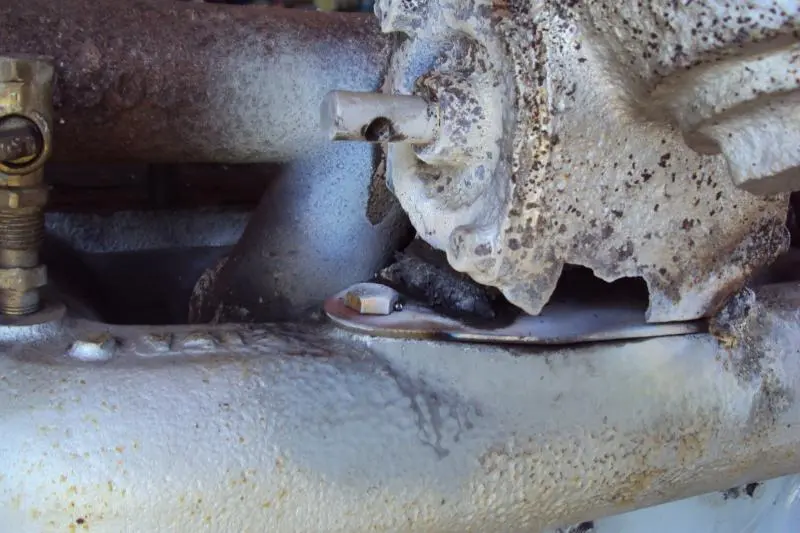

I have a John Deere D with the exhaust ports burned out of or off of the cylinder head.

The attached pictures show that it is paper thin down at least 1/2". The previous owner

tried to fix it with JB Weld to no avail. The inside port on the head is good; it is just the

ones to the outside that are burned out. I don't know whether they rusted away from the

outside or burned away from the inside, or if it is a combination of both. This is a 1938

D JD, so I have a concern as to how many times the head has been hot and cooled off

and if it will accept any kind of weld or build up material.

I have inquired at Williams Cylinder Head Company in Nevada, Iowa, to see if they can

build this back up, but haven't had any response. Just wondered if anyone knows of a

way to build it back up and get a good surface on it so the exhaust manifold gaskets

will stay in? The head is in good shape otherwise, so I hate to junk it. Thanks for any

responses.

[attachment=14880]JD D Head 001.jpg[/attachment][attachment=14881]JD D Head 002.jpg[/attachment]