Cats Forever

That is an Old one!! Looks a lot like the old BJ but could be a Gould or some of the similar ones.

[attachment=68277]Byron Jackson pump..jpg[/attachment]

Thanks for posting this! This kind of setup is exactly what I'd like to take to the show to run my belt pulley on. How big do you think that pump is? It would be very cool to see it restored and I can't imagine it would take much, given there's nothing to them. Seems a shame to see it sitting there in the river. What mechanism would they have used to prime it?

John,

I suspect that photo of IGZ Decal is one of those I submitted years ago. Probably in one of the postings of Dealer Decals?

RE: Pump and small pipe with half union on the upper end of the volute housing --- yes, that is where they would have pulled the air from the system (Prime) and in many cases even today on the smaller applications they use a hand pump. For example a Douglas or other make with a piston seal and flap (check valve) in the bottom of the piston chamber.

One must remove all air from the pump or risk cavitation problems and ruin the impeller.

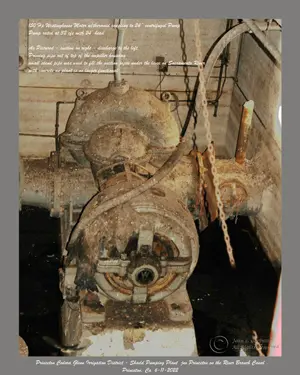

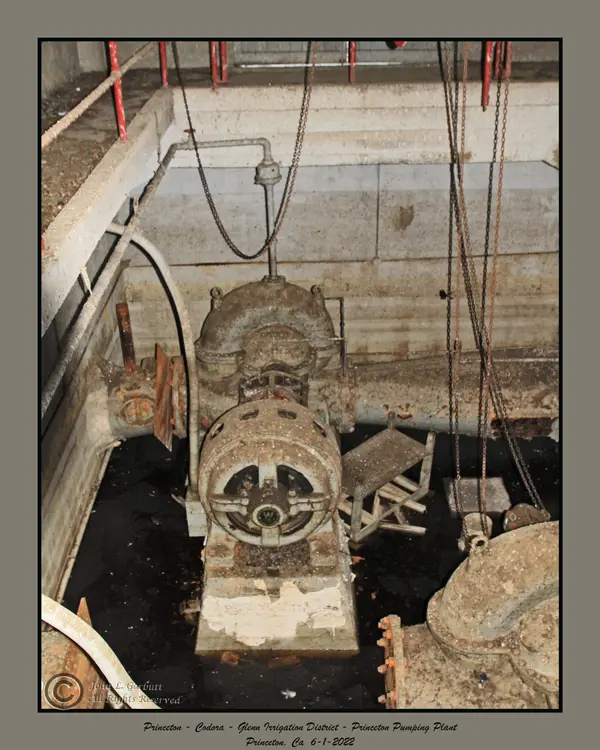

The attached photographs are from a Irrigation District pumping plant --- this plant had 3 pumps powered with 150 Hp Westinghouse motors, pumps were rated at 30 Cubic Feet Per Second at 24' head. This particular plant has not run in many years. One of the pictures shows the priming pump on the right side of the motor and the sump pump on the left side.

These plants were all way below ground grade - in a pit - and as evident in these pictures - you can see standing water and the "bathtub" ring where the water has risen over the equipment in the past years. The suction side of these pumps has been blocked off - the pipes filled with concrete as they penetrate the levee placed for flood protection.

That is why you see a plate and the small pipe rising from the suction side of the intake pipes.

Hope you have taken a trip into yesterday - there are few locations locally that still have intact centrifugal pumps, let alone operating plants. Reclamation District 108 has at least two large plants running centrifugal pumps.

cts

In case anyone is interested below is a link to the museum I used to volunteer at which has several very large diesels which were used for drainage in the Fens, sadly no Caterpillar diesels. There is, however, out in the yard a large Worthinton diesel engine with centrifugal pump, awaiting restoration which was made in the USA.

The Mirrlees engine is unusual in that the fuel is injected by compressed air (at approx. 600psi) rather than being mechanically injected.

Our collection - Prickwillow Museum

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

another method is to have a drum or bucket of suitable size above the pump and filled with enough water to prime the system to the pump. a hose with shut off is fitted to the drum and runs to the pump. you simply open valve count to 20, start pump, wait for drum to refill and turn off valve simple and it works they had a old chemical drum for this purpose on the top of the bore pump house at school every few yrs fit another drum as it got brittle from the sun. it was a line shaft turbine pump the shaft guides were water lubricated.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

i worked on a 6cyl k series mirrlees-national in a ocean going tug. priming the oil was around 40 strokes on a hand pump till it spilled over in the sight glass. she made 1800hp at 450rpm. she started on 400psi air but full mechanical injection.

my mates boy couldve stood in the cyl mind you he was only 4.