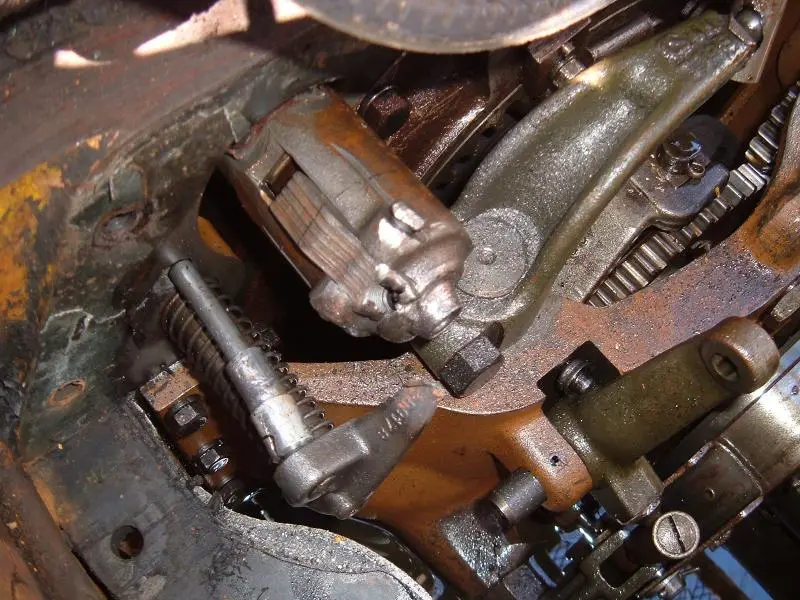

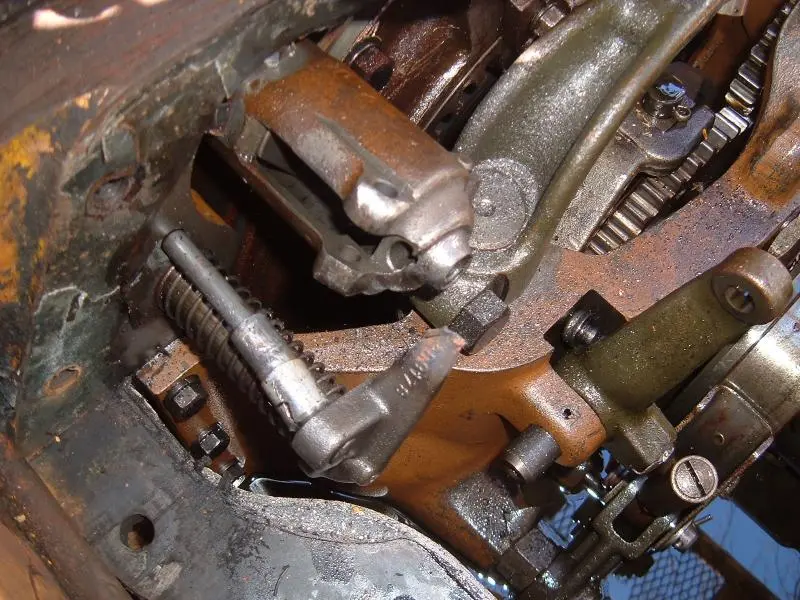

Here are the pictures of some of the damages. One side of the pinion sleeve [attachment=35174]DSCF0447.jpg[/attachment] The other side with a missing latch. [attachment=35175]DSCF0448.jpg[/attachment] The overall look. [attachment=35176]DSCF0449.jpg[/attachment]

I wonder if the sleeve can be saved by some welding, a bit of machining and some new latches, springs and adjusting screws. I'll have to cross that bridge when I get the parts out.

Now to get the clutch out. The split coupler has been removed. When working bent over and at arms length all of the parts are definitely 32oz. to the pound.

Worst thing to leave a pinion go bad with an oil clutch, all those grindings, most likely the clutch pump is bad, sorry to rain on your parade but found that out on one i rebuilt.

Gary

You have to drain the housing cluch and check the screen for small pieces and check the oil pump and you should removed the cluch ass. maybe some broken parts inside and if I can help am still have some used parts

[email protected]

As soon as I get the clutch out I'll tear it apart and see what the damages are. At this point in my life I like to have somebody around, not so much to help, but to call 911. We'll see what happens tomorrow.

Amen to that. A lot of us are riding in that boat.

Here are the pictures of some of the damages. One side of the pinion sleeve [attachment=35174]DSCF0447.jpg[/attachment] The other side with a missing latch. [attachment=35175]DSCF0448.jpg[/attachment] The overall look. [attachment=35176]DSCF0449.jpg[/attachment]

I wonder if the sleeve can be saved by some welding, a bit of machining and some new latches, springs and adjusting screws. I'll have to cross that bridge when I get the parts out.

Now to get the clutch out. The split coupler has been removed. When working bent over and at arms length all of the parts are definitely 32oz. to the pound.

[quote="Norm R2,22"]Here are the pictures of some of the damages. One side of the pinion sleeve The other side with a missing latch. The overall look.

I wonder if the sleeve can be saved by some welding, a bit of machining and some new latches, springs and adjusting screws. I'll have to cross that bridge when I get the parts out.

Now to get the clutch out. The split coupler has been removed. When working bent over and at arms length all of the parts are definitely 32oz. to the pound.[/quote]

My D2 had the exact same thing happen to it. I had a friend/machinist at work make me a new sleeve and found a replacement pinion latch bar thingy from the Zimmerman boys out in Iowa.[attachment=35179]PICT0564.jpg[/attachment] That was pretty easy to repair but I had the engine removed for other repairs at the same time. You might be lucky with a D4 as I'm sure it has more room to work on it.

If it's the same as a D2, it'll need to slide back another 5" to be removed. Do you have that much space with the engine still attached to the transmission? I don't have a D4 service manual so don't know if removal is required. You could try welding the piece back on and straightening the secondary guide in-situ. Worth a go - if it works, you saved yourself some work. I straightened mine even though the engine is out, because it's easier to see if it lines up when it's still installed

Bailed out the oil in the clutch compartment with a 16oz cup till I couldn't reach any further. I then used the shop vacuum to finish the job. I removed the pickup tube and checked the screen. The screen was intact and there didn't appear to be any chips or crud in the tube. The flange that bolts to the pump had one of the ears broken but that should be able to be brazed. Now to get the clutch out. Do I start with the bolts on the flywheel or the bolts that hold all the brackets and the pump? The collar that slides to engage the clutch is warn to a knife edge on the front side. That will probably have to be replaced.