94 visits and no reply ... come on guys, tell your opinion!

if you do not understand some of what I wrote, I will try to explain. I do not know much English!

thanks

See you soon

Just a guess, but if fuel is leaking out, air is probably getting in when off. Air getting back to the injection pump distribution manifold would really mess up the overall prime.

Other ideas???

I would fix the leak for sure then go from there.

Dan

If the fuel is leaking up past the thread of the retaining nut, it is probably leaking between the nozzle holder and the nozzle lower down, probably because the nut has been overtightened at some time and squashed the nozzle down, this will also allow compression past the nozzle seat in the pre-combustion chamber and blow combustion gas past the nut and back down the fuel line, causing the fuel to aerate, the sleeve metering fuel system will put up with some of this until ithe engine is stopped, then the air separates from the fuel within the injection pump, causing air in all the fuel lines, then the engine will not start.

In other words, fix the fuel leak first, take the injector out, make sure it has a good seat in the chamber, make sure it is not squashed down, check there is a good clean seat between the injector and it's holder, put the retainer nut on with no seals first, to make sure it is clamping the injector and not going tight on the chamber top. If all this is OK, there should be no leak, but I reckon you will find the fault in these checks.

Hi catsilver,

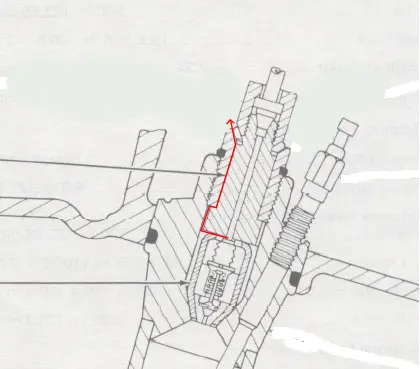

thanks for your answer, as I understand it, the fuel flows as shown in Figure No. 1.

[attachment=14882]Figure 1.jpg[/attachment]

My problem is that I can not unscrew the holder with key 1-inch. I'm afraid that doing a lot of strength I can break in the prechamber.

Do you have any solution?

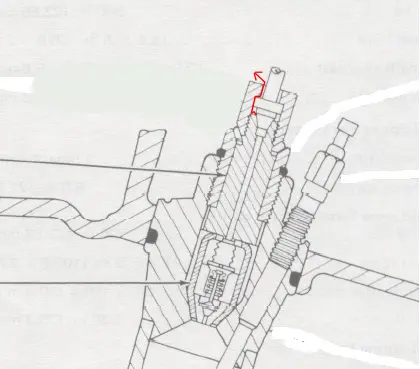

E 'possible that the leak occurs as in fugura No. 2?

[attachment=14883]Figure 2.jpg[/attachment]

thanks

Annulla modifiche

Hi cat 951, It is possible that the fuel is leaking as in figure no2, a check of the condition of the injetcor pipe end should confirm this, but if someone has screwed the top nut down so tight that you cannot get it off, they have doen this trying to 'cure' the leak. If you can't fix it by cleaning up the injector pipe end, you may have to get that top nut off, but drain the coolant out first, because the whole precombustion chamber may come out.

In a older tractor had fuel leak as in your last picture.Used emery cloth and dressed the ferals which fixed most of them.I think the nut bottomed out on the ones that still leaked so rapped teflon tape on top of the of the feral which fixed the rest.I don't us this tractor that much and it has lasted, but in your case of a working machine new fuel lines are probable the way to go.

Ray

You will need an 1" socket and long bar to remove the injector retaining nut ,as at assembly the torque for that retaining nut is 100lbs ,precombustion chamber torgue is 150 lbs

clean taper in precombustion chamber ,and male taper on injector ,screw injector hand tight to splinded injection tube ,install injector and tube in precombustion chamber apply antisiezer compound to retaing threads ,and torque nut to 100lbs

If leak is solved ,and hard starting continues check rack limiter on governor for hanging up