You have a wonderful day. Best wishes. Deas Plant.

Hi, Bernard.

Looks like a nice catch, at least from the outside. Nope, there were no dedicated tie-down points on those old girls. I suspect that the ones made for the military had tie-down points but I would not put money on it,

I would not rely on the circle to hold it. Personally, I would chain to the front axle front support arch pulling forward and to the tandem cases pulling back.

There are likely others here who will know better.

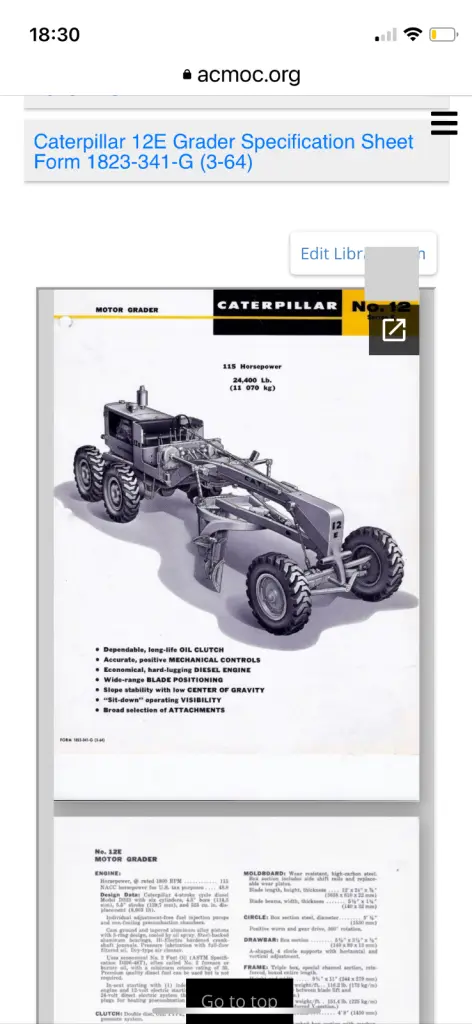

A couple of pages that might be helpful to you:

https://www.acmoc.org/library - if you are a member.

8th post down on this page:

https://www.acmoc.org/bb/discussion-d72/11465-home-at-last#91423

Just my 0.02.

12E, s/n 99E12344 built 1965

Thank you Deas Plant and Bruce Oz. I do have the service and operation manuals and have submitted scans to the library. (Although the same or similar publications are already in the ACMOC library, my scans are better. I've been digitizing books for many, many years.) The photos in the service manual were really well done. The lighting and staging were immaculate, and you can see that they were shot in medium or large format, not 35mm. The care and money it took to produce these manuals, and especially the photos, is a remarkable achievement. I recently digitized a Case manual from the 1990s and the photo and print quality is nowhere near as good.

And I've typeset Deas Plant's instructions, attached.

You have a wonderful day. Best wishes. Deas Plant.

Hi, Bernard.

If my understanding 'kee-wrecked', Cat parts manuals have a LONNNNGGGGG history. I have been told that when Benjamin Holt sold his first tracked tractor, #111, to a sugar farm in Florida, he sent a a 'parts book' with it. This 'parts book' had photos of EVERY part of the machine from ALL the angles necessary to be able to show ALL the dimensions of each part so that the new owners could fabricate parts for themselves 'coz there weren't any overnight air services back then.

Thank you for the digitized version of my 'rantings'.

Just my 0.02.

Bernard,

Thank you so much for providing the new scans of the OMI and Service manuals for the 99E No12 grader which I have now added to the library replacing the previous inferior copies.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

the hydraulics not working being due to trapped air is possible. a sign of this is the pump being very noisy and cavitating so it will make a humming /buzzing noise as you cycle the system and as the air clears it should reduce. to bleed each function you want to full stroke each item each way one at a time have a helper keep topping the tank keeping it above the minimum line. but not full as you need to allow the air out or you can suddenly get a big glug of air and oil goes every where as it over flows the tank.

NOTE this is only general advice on bleeding hydraulic systems. the service manual for the hydraulics will have the correct procedure.

and as deas said you chain the axles down nowhere else and yes you lower the blade and rippers if its on the ground it cant move a coupe of bits of dunnage(timber) between the cutting edge and the trailer deck saves the deck and helps keep the blade still particularly on steel decked trailers.

dont chain the blade circle as away to hold it down its only made to carry the blade and the forces as the blade is working. not hold the machine on a trailer. these old girls didnt have dedicated chain down points no machinery did back then. people were expected to just know how to do it and use common sense before all the oh&s laws and requirements came in and this stuff was thought of.

a rough rule works with all wheeled machinery if you chain the wheels/axles down you will have pretty well held on. and is sufficient load restraint provided your lashing equipment is suitably rated for the load mass.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality