I have been working on my Ten as well and noticed an oil leak at the front pulley. I thought it was a regular seal but now I know different. What is the seal number you used.

Thanks......Bill

How does one size the ID of the seal, given the shaft size or vice versa? The shaft is slightly larger OD than the seal ID - but is there a rule of thumb or does the seal manufacturer state the shaft size that his seal fits?

Cheers,

Neil.

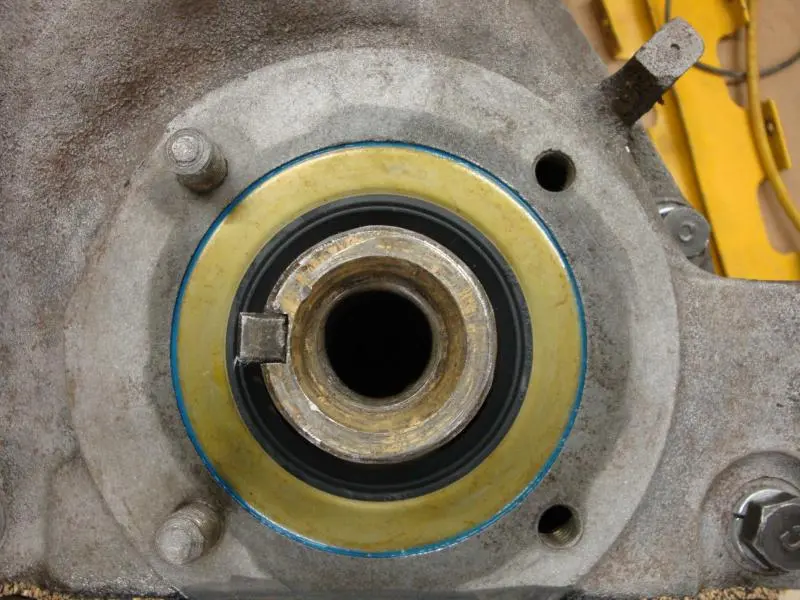

I actually used a magneto drive seal for a farmall cub. The seal will need to be cut down in thickness from the 1/2" that it comes to 1/4" which is the more difficult of the machining. I found that after removing the extra metal it fits the casting loosely so I put it in with some locktite. Then I plan on putting a small amount of silicone before putting on the metal cover plate and I think that it will be secure that way. If you have a good auto parts store they should be able to find a seal with the exact sizes needed to fit the opening without altering it. I just used what I had. Once I fit the seal I turned down the pulley to 2.162" and polished it. I will let everyone know how it works when I am finished.

How does one size the ID of the seal, given the shaft size or vice versa? The shaft is slightly larger OD than the seal ID - but is there a rule of thumb or does the seal manufacturer state the shaft size that his seal fits?

Cheers,

Neil.

[quote="Neil"]How does one size the ID of the seal, given the shaft size or vice versa? The shaft is slightly larger OD than the seal ID - but is there a rule of thumb or does the seal manufacturer state the shaft size that his seal fits?

Cheers,

Neil.[/quote]

seal catalog is usually arranged by nominal shaft size and then lists alternate OD, width, style and material. Most have a recommended housing diameter (seal OD less a thousandth or so for a secure fit)

the repair sleeves mentioned here increase the shaft diameter slightly, but the manufacturer usually recommends the same seal with or without the sleeve.

With the liminted number of hours one of these old CAT's will ever see, I would save the speedy sleeve $ for some other part of the project. If it ever wears a groove, someone in the next generation can install one.

One of the handier books out in my shop is an older CR Seal handbook that I scored at the "local" NAPA store a few years ago. It lists (I think) all the seals that they made up to that point. Now when I need a seal, that's the book I get out first. It gives the outside, inside and thickness by bore size and shaft size plus what the actual sealing material is.

Sure beats trying to pry an old seal out while trying to preserve the numbers on 'em 😆

The other book I get into quite often is the old SKF bearing book I acquired at the same time. Same format, ID, OD and width for both ball bearings and roller bearings plus in the case of ball bearings whether they're sealed, shielded or open types.