[attachment=73046]IMG_5036.JPG[/attachment] [attachment=73045]IMG_5035.JPG[/attachment] [attachment=73044]IMG_5033.JPG[/attachment]Here is the McMaster link and a few pictures of the ones I bought several years ago. They are stamped Alemite Made in USA. I can not say where they are made now.

https://www.mcmaster.com/products/grease-fittings/pin-style-grease-fittings/

And the link for the couplers, click on the box "for pin type grease fittings" on the right side of the page and it will open up a few choices for the couplers.

https://www.mcmaster.com/products/grease-fittings/grease-dispensing-tips-8/

Catman how far along are you on the Best 25 project? Skinner

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

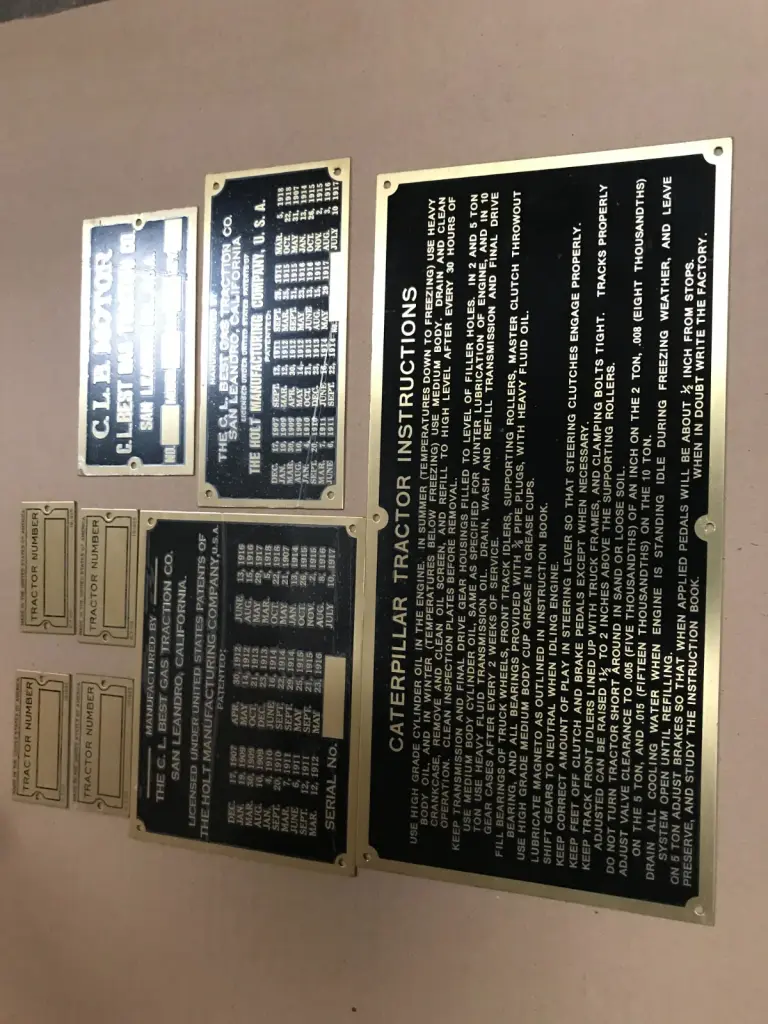

Nayorbros Hello Sir. Thanks for the intel I will Stamp ALEMITE. (MADE IN USA). Can you confirm I have looked at your photo correctly . Ideally send myself a Carbon Trace or Roll in Engineering Blue. Will work fine. Thanks on the Detail.

Yeap I did find those on McMaster website and looked to be nickel plated steel or brass in the photo. I checked the spec page and it said brass for Body Material Zinc Plated Steel for the Pin Material. Steel for the Ball Material. With no mention Spring Material thinking Steel for Spring also being in Grease LOL. So decided simple option (.MADE EVERYTHING ELSE.) Might as well make these too with addition Stainless Steel Pin, Spring and Balls. Idea Being these will NEVER go rusty.

Skinner. Which One. Next time your passing my place Call in at Cat-Cave HQ and see for yourself Kettle is on Smile. I have been working on the VERY BEST today HeHe. Sand Blasted and in Red Lead Oil Resistance Internal Oxide also on the Inside. Before Casting new Crankshaft Bearings. We need to Cut out the Bottom Oil Feed Pipe, and machine and refit a new one. Not a simple job. But the last TIME I spoken with Jim Z. several years ago he told myself he only known of 6 Known to Exist. Casting them 4 spoke Idlers and new Cylinder Jugs without the water pipes was FUN What do you think Skinner ? Remaking Piston Rings and machining oil rings ATM

Trainzkid88, Those giant button head fittings from local CAT Dealer do not fit. My track rollers have the Old Style Hidden inside a Bored Hole inside the end of the Shafts. You cannot really see them LOL Using a ZERK fitting not in keeping with this Level of detailed restoration project.

CM

I might have the print for the pipe. I can send a fitting with the carb kits

nylorbros Sound Good.

I am thinking 3 Stage Progression Ground Fit In 3 Different Size Journals, With Relief in between Journals. With Pre Drilled Holes in the Pipe to line up with Journal Outlets . So Need to Get the Angle Lined Up also As Well before Pressing inside that Crank Case. Working back to a Print Would be very Helpful. Send over ASAP to CAT-CAVE HQ. Do you need any More CAT-CAVE BRASS PLATES, DECALS and Cat-Cave Clothing adding to your Order ?. Cat-Cave CL BEST Logo on Boxer Shorts and Socks back in Stock.

CM

Sounds like youv'e come off yer spool catman! Better check yer air filter!

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality