"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

i have a parts book and here are the part no.s for a 44inch guage tractor 13 inch heat treated shoe 3B2778 which transfers to 4K7052. bolts are 8H-1584 nuts 8H-5724 lock washer 3B-4508

find your self a parts book that cover your machines serial. it is very helpful to have. a owners book and serviceman's reference are another 2 book to get. try ebay for the books.

if the grousers are only worn down you can also rebuild them by welding on pieces of grouser building bar, medium grade steal flat bar or even deformed bar you must use low hydrogen 6018 0r 6016 welding alloys to do this and prevent cracking gp rods can crack easily and often wont hold on medium tensile steels. 6016 also known 16tc or twin coat are the easiest low hydrogen rods to use and most cost effective.

edb has posted data sheets on the reclamation process it was also in issue 152 of the acmoc magazine pages 40 to 44.

if you contact your local dealer they may be able to find you a listing and give a price for new grouser shoes make sure your seated as sticker shock may get you. just remember these are machines in preservation not working machines there days hard work is long finished and don't need to be perfect showroom condition unless you want to spend an absolute fortune and never get it dirty.

aftermarket parts are available for some machines too.

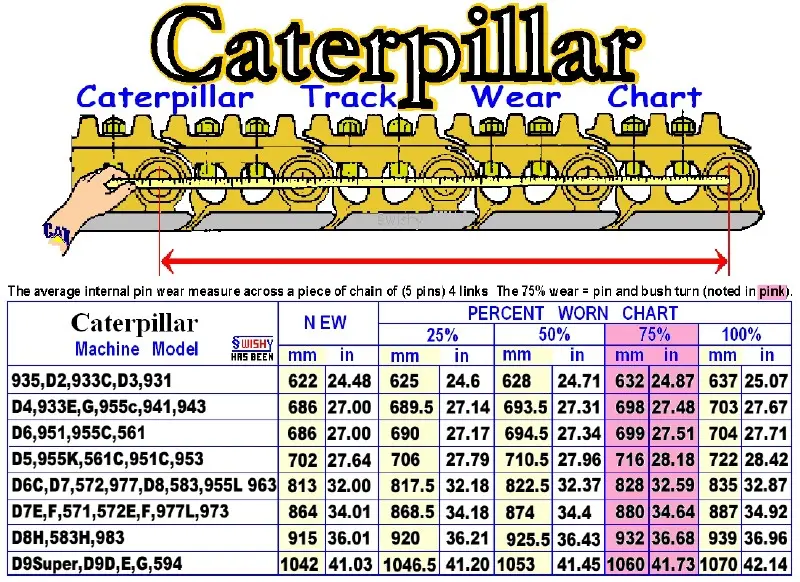

[attachment=61390]cattrackwearchartaf3.jpg[/attachment]

I went to a steel fabricator and he had a bunch of 3/8 A588 plates that he cut out a whole set of 1 1/2' bars I welded them to my grousers with 6013 rods

[attachment=61397]ibm 254.JPG[/attachment]

I went to a steel fabricator and he had a bunch of 3/8 A588 plates that he cut out a whole set of 1 1/2' bars I welded them to my grousers with 6013 rods

[attachment=61397]ibm 254.JPG[/attachment]

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

[quote="dpendzic" post=224206]I went to a steel fabricator and he had a bunch of 3/8 A588 plates that he cut out a whole set of 1 1/2' bars I welded them to my grousers with 6013 rods

[attachment=61397]ibm 254.JPG[/attachment][/quote]

6013 are general purpose rods not controlled hydrogen 6018/6016 are hydrogen controlled. the reason for using them is crack resistance and higher tensile strength in the finished weld.

hydrogen causes weld enbrittlement and cracking so does very cold or damp/wet steel.