Cats Forever

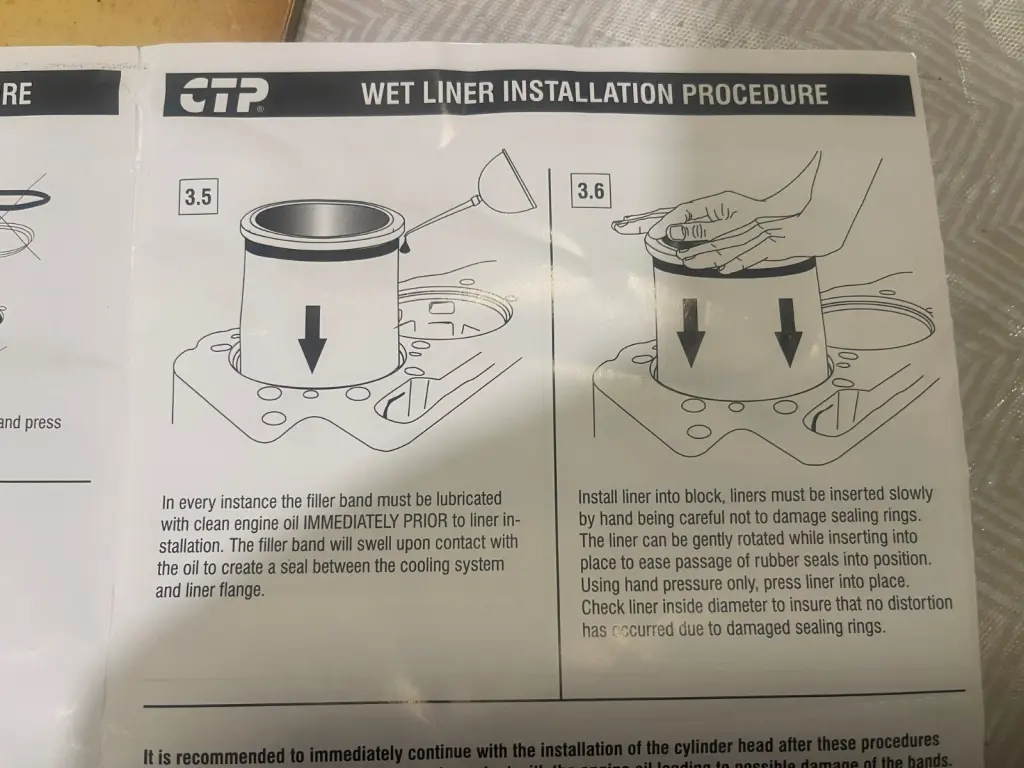

I have Never put a liner in a Cat but many in John Deere with an O-ring. Make certain the shoulder in the block is squeaky clean before lubing and installing the O-ring and liner. Make certain you have the correct size O-ring. For what it is worth I always used soap as the lubricant as oil often causes swelling and makes the installation difficult. Don't get hammer happy but gently use a dead hammer to gently get the seal started. Hope that helps.

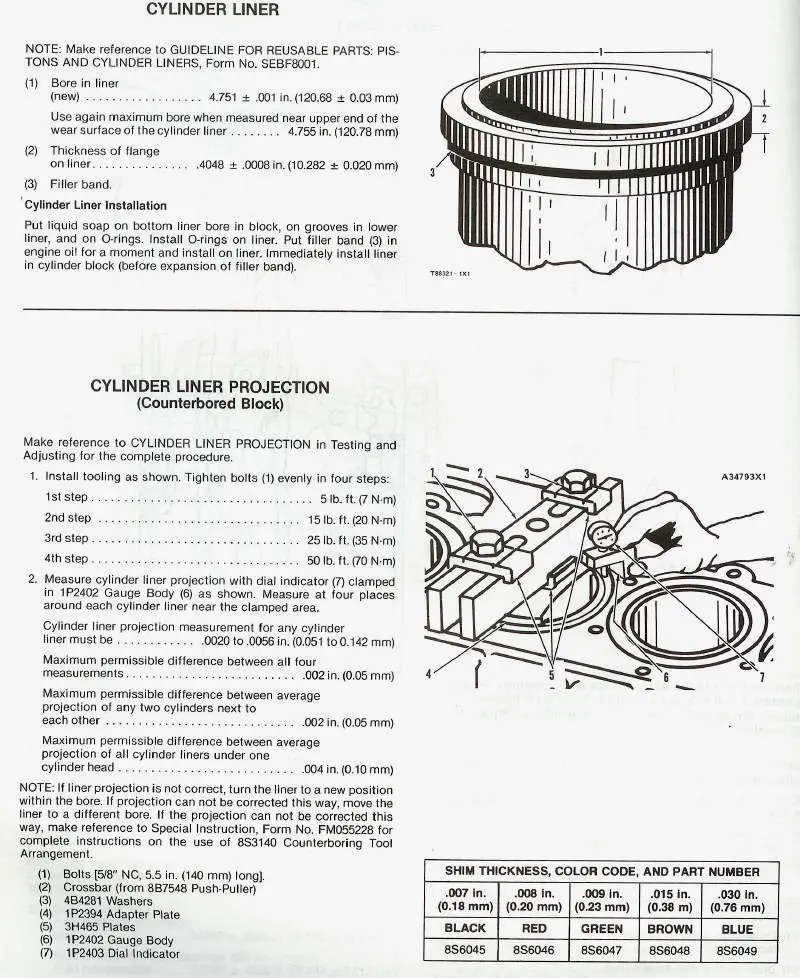

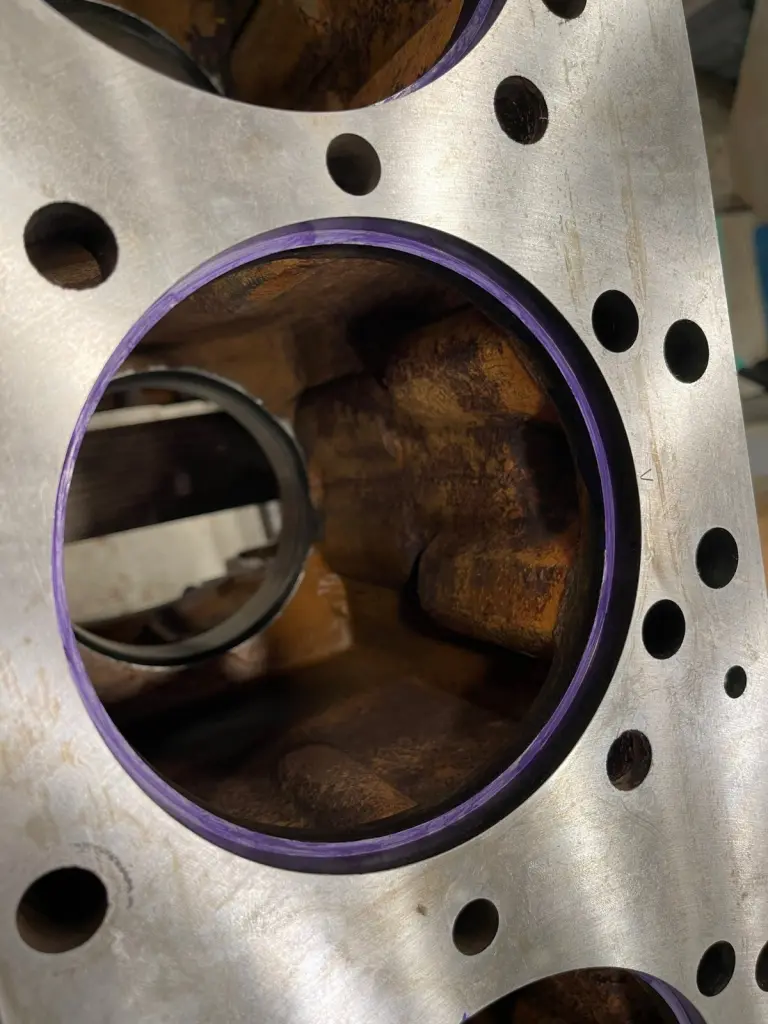

Use the the metal shims and check liner height. Check those new liners too, know of a shop that used CTP liners on a 3408 and two of the eight were egged shaped and wouldnt fit in the block.

Does the shim under the top of the liner flange actually provide a seal or is that the job of the head gasket? I think I might be think about this wrong. Can coolant technically get past the shim and around the flange only to be stopped by the head gasket?

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

the oring is the seal. the shims sets the liner height.

What o-ring? I realize the 3 o-rings at the bottom keep the coolant out of the oil but what seals the top of the liner?

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

Hi Alex,

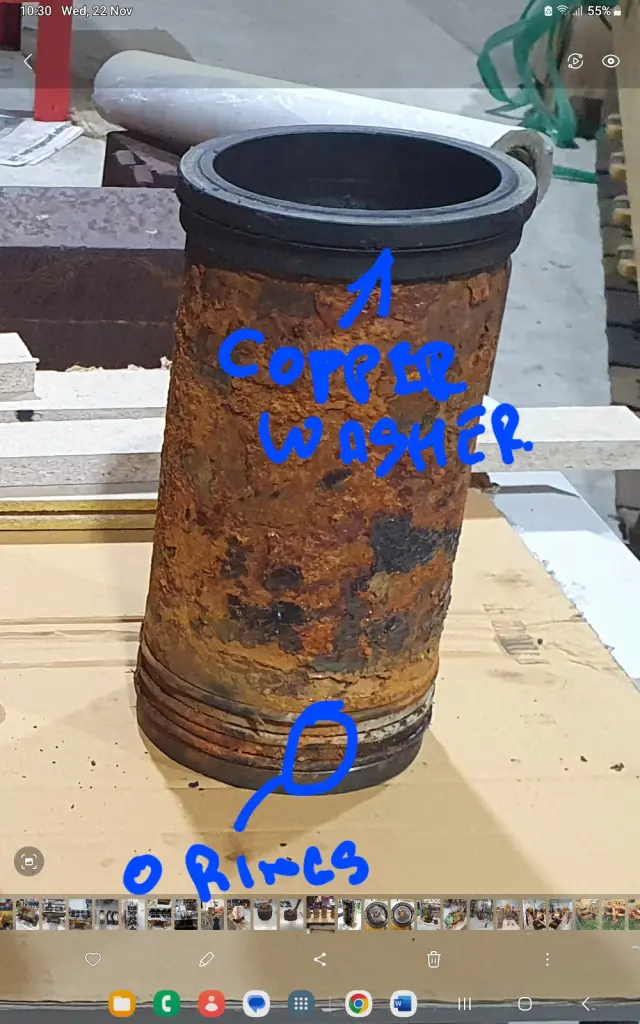

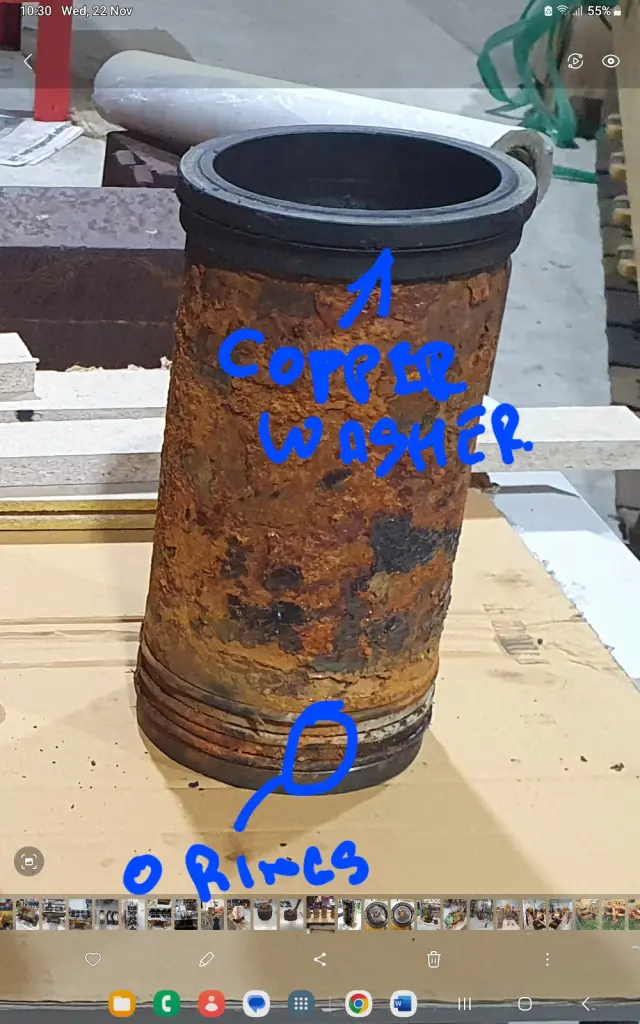

Here is a photo of the old liner i pulled from my d315 showwing where things go.

Do not to forget to set the liner hiight this is done by placing the copper washer under liner top then place the liner in the block (no orings yet) an place a bar across the liner top and measure the clearance between the bar and block, i dont have the specs so i call on OM do you have them please and the diagram on the setup please.

Once you have them all within spec you can then install them with the orings on.

[attachment=74375]20231122_103321.jpg[/attachment]

Regards

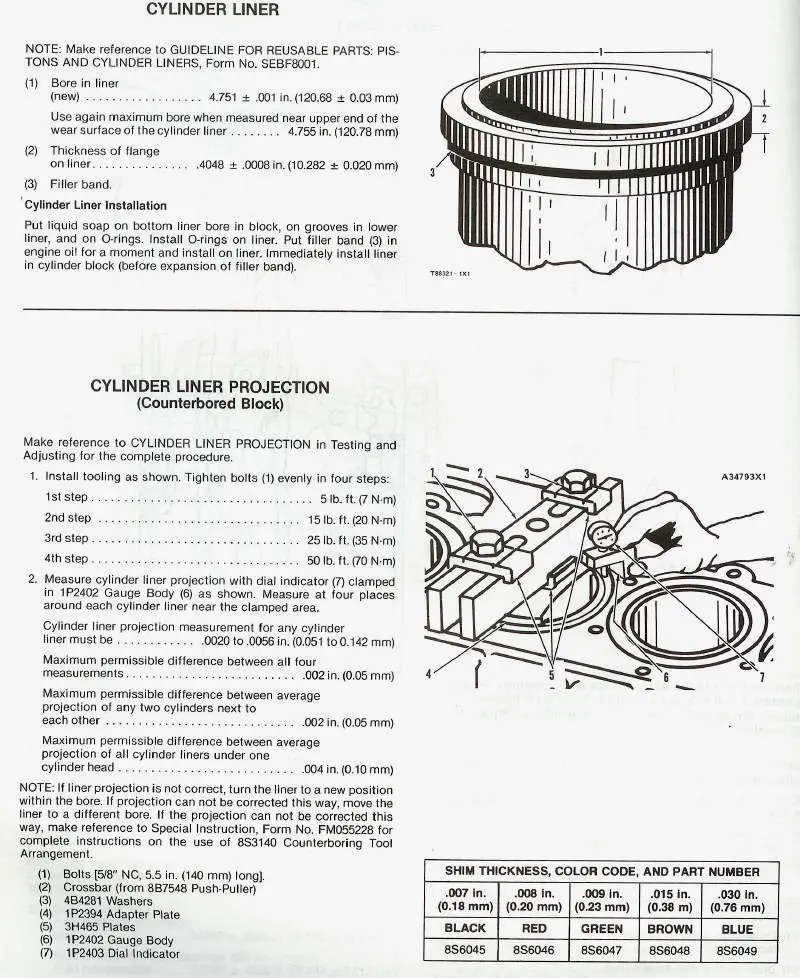

This is for the 4-3/4" bore but most of the specs apply.

[attachment=74376]Liner-Proj.-3306---D6C.jpg[/attachment]