Where did you get the 8F2657 number? I think it may be a component in the 8F2666 group.

I believe you are looking at a casting number which is not the same as a part number in most cases but the part number is often just a few digits off.

8f2657 is a casting # on the rear eyelet. Cat did say this is a obsolete# ,superceded by more obsolete #'s. I did'nt have the page on 8f2666 at the time to clue them in on what I have. I came across 8f2666 by accident ,not sure what year range this applies to.

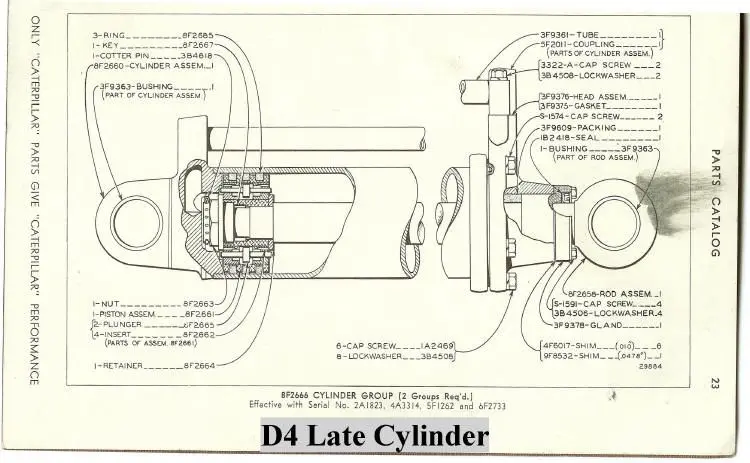

You apparently have group 8F2666. The rod assembly, 8F2658, consists of rod casting 8F2657 and bushing 3F9363. However the seal could be either 1B2418 or 1K6981. The gland and seal were changed at higher serial numbers. Is your blade assembly serial number marked? It should be on the rear side of the moldboard, upper right area.

I think it's safe to conclude you have the late style cylinder.

The rod packing 3F9609 is still a good number but it now uses entirely different (2-piece if I recall right) parts.

Last time I got a Cat seal the 1B2418 was a 9H2258.

Also can use a National 450083 or CR 19886

These all are kind of an odd seal with open case to the outside?????

I think it's safe to conclude you have the late style cylinder.

The rod packing 3F9609 is still a good number but it now uses entirely different (2-piece if I recall right) parts.

Last time I got a Cat seal the 1B2418 was a 9H2258.

Also can use a National 450083 or CR 19886

These all are kind of an odd seal with open case to the outside?????

Hi OM,

i am guessing by your ??? that you are searching for the reason these seals are fitted with the lip facing outwards.

They are dust wiper seals, so to function as such to scrape any dust from the rod this is how they must be fitted, if faced the other way about they would slide over the dust and allow it to enter between the packing and the seal itself. I have seen wipers fitted backwards and the space between the wiper and first packing was crammed hard with dirt causing premature scoring/wear of the chrome on the rod.

They also would help seal any dust/water entry to the system if the system were to have a vacuum in it. The packing takes care of the higher oil pressures by virtue of the chevron packings facing inwards, the dust wiper seal takes care of the outside stuff. In effect the system is protected/sealed in both directions.

Hope this helps.

Cheers,

Eddie B.

That style seems to be the norm these days, I had noticed that as well.

(JD 310D backhoe with almost every cylinder needing to be repacked, I'm working on them slowly)😆

I think they are hoping having the face of the metal ring deep in the recess will help the wiper seal stay put.