Cet119

Charlie,

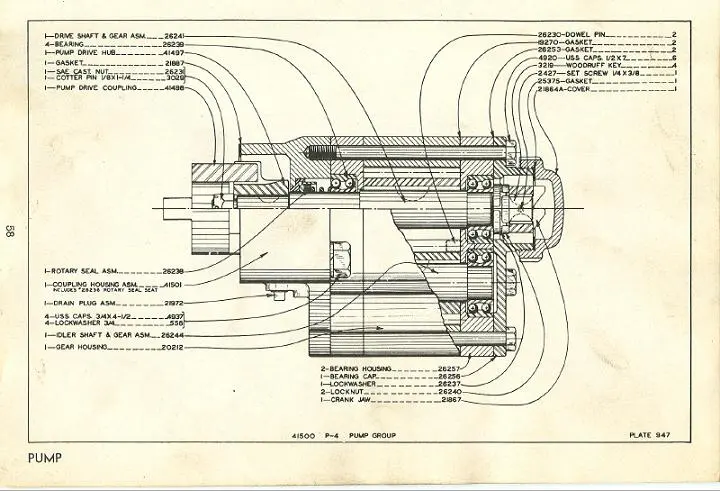

I don’t recall any cork gaskets in the pump for the 4R Trailblazer, tho they did requiring placing shellack on the face the gear case as these were ground and lapped joint which did not require a gasket. In some case they were a real thin paper gaskets use as gear house gasket on some units as I recall. I’d think the rotary seal assembly (parts number 26232) is the part that is causing the leak, if it is and the shaft is wore, you may have to use a ware sleeve on the shaft, or have it build up and turned down to the right size. Here is a couple of photos that may help. Let’s us know how things work out.

Kelly

[attachment=19977]LaPC_frontoilump.jpg[/attachment][attachment=19978]LP%Chrearpump%pressuresofreliefvalve.90008.jpg[/attachment]

Thats an interesting comment you made that the pressure wants to stall the engine1

I would wonder what the relief valve is set for?

Your leaks maybe coming because of that.

never heard of a cork gasket between sections, can't imagine it sealing very much in a pump application especially at 1000PSI, normally they are a very thin piece of metal or paper. most newer style pumps use rubber seal that has the cupped side open to the discharge housing so that the pressurized oil can get behind the seal and expand it to make it seal better, a lot of the time they have brass plates that ride against the gears and the seal is behind the brass plates, it has a secondary function of reducing internal leakage past the sides of the gears. the paper and metal gaskets of old were very thin to also reduce internal leakage past the side of the gears. i have rebuiltgear pumps and used loctite 515 or equivalent metal flange sealant. it sets up and is about 0.001" thick after you bolt the halves together. as long as the gears still turn easily you should be good. if you have to use a wrench or pair of pliers to turn the shaft the end play is too tight and the pump will score the end housings or gear sides(faces) from lack of clearance. you can use metal shim stock to make your own gasket for between sections, it comes in brass or steel. and usually you can cut it with scissors. just make sure it isn't too thick as it will increase the end gap or float of the gears to the housing and you will have internal leakage past the gear faces.

The 4-R Trailbuilder should have the pressure set at 450 psi. Even though 1000 psi is possible for other applications such as the Carrimor scrapers.

drujinin:

Comment about the pressure being set to high, could well be right. As a suggestion, one should make a pressure test with a hydraulic oil test gauge which has a pressure capacity of at least 1200 lbs. As, mentioned the maximum hydraulic relief value pressure is 450# for the dozer model in question. You might as a safety precaution back off the pressure relief valve some before testing the pressure and then raise it back up as needed to meet the 450# limit.

Kelly

Thanks for all help, did have a gauge hooked up and cranked the pressure back to ~450 by which point most of the cork had pushed out of the flanges. Then took the pump apart, and reassembled with 515 instead of the previous owners cork. Only thing left is what to do with the shaft seal, all the parts look OK with the exception of the rubber, will try the local hydraulics shop and see what they have.

I just received in the mail a parts book for the C45 scraper dated 4-45 if I am reading it correctly. It has a diagram for the P9 pump with a notation "Pumps with round power and suction port bosses uses #19270 gaskets (2 ea) and the pumps with the octagon bosses do not use gaskets"

Stephen, I have a C-45 scraper where did you find the parts book and could you make a copy for me

Thanks

Chuck C