That's a common problem when they get loose right away, the seals in the adjuster piston get bad and the grease gets past them. might have to replace the tube the piston is in if its pitted or rusted bad.

Gary

The track will come off much easier if it is really loose,more flexing is more ware to track as well.Need to fix it.

Thanks guys. Looking at the spare parts book and service manuals doesn't seem to tell me how to remove and replace the hydraulic piston. Do I presume correctly that I will have to split the tracks, and move/remove the front idler to withdraw the piston? Are there any dangers associated with the compressed recoil spring?

Unbolt idler extension flange from the adj cylinder, force/pull idler forward and hold it there. Take channel locks and try to pull the piston out of the adj cylinder. If you get it out change the seals on the front then reinstall it. Bolt flange back to cyl taking care of the seal rings. Pump grease into adjuster and see if it holds. If not the track will need to be split and adj cyl replaced aswell.

Recoil will be safe if front pilot is held by the front anchors on the frame rails.

Later Bob

Thanks Bob. Job underway with the biggest hassle being removing the guarding over the track spring without taking the blade off but I got there. I ended up splitting the track, manually jacking the idler forward until I could get a spanner on the bolts at the cylinder end flange then unboltong the idler extension rod at the idler end and removing it. It was then easy to pull the big cylinder out and then pul the small piston inside it out. The bucket/seal on the small piston had crumbled hence the leak. The cylinder has a few rust patches on it but the bore inside the spring looks OK so I will just clean it up and replace all o rings and seals. More to follow.

Ian

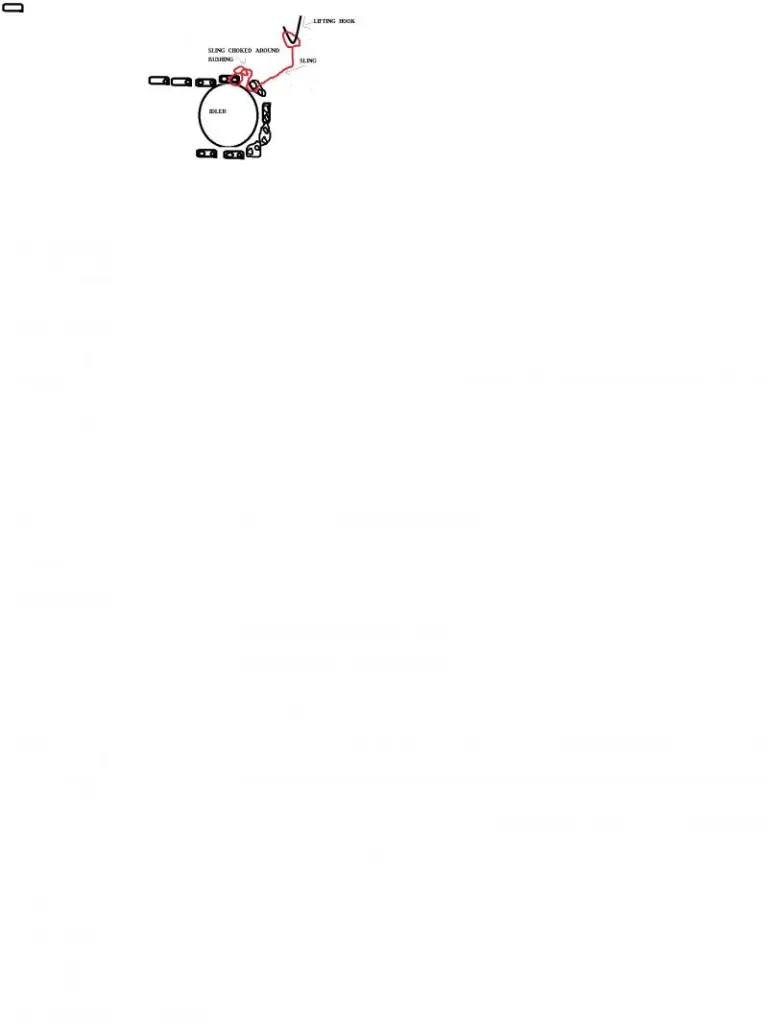

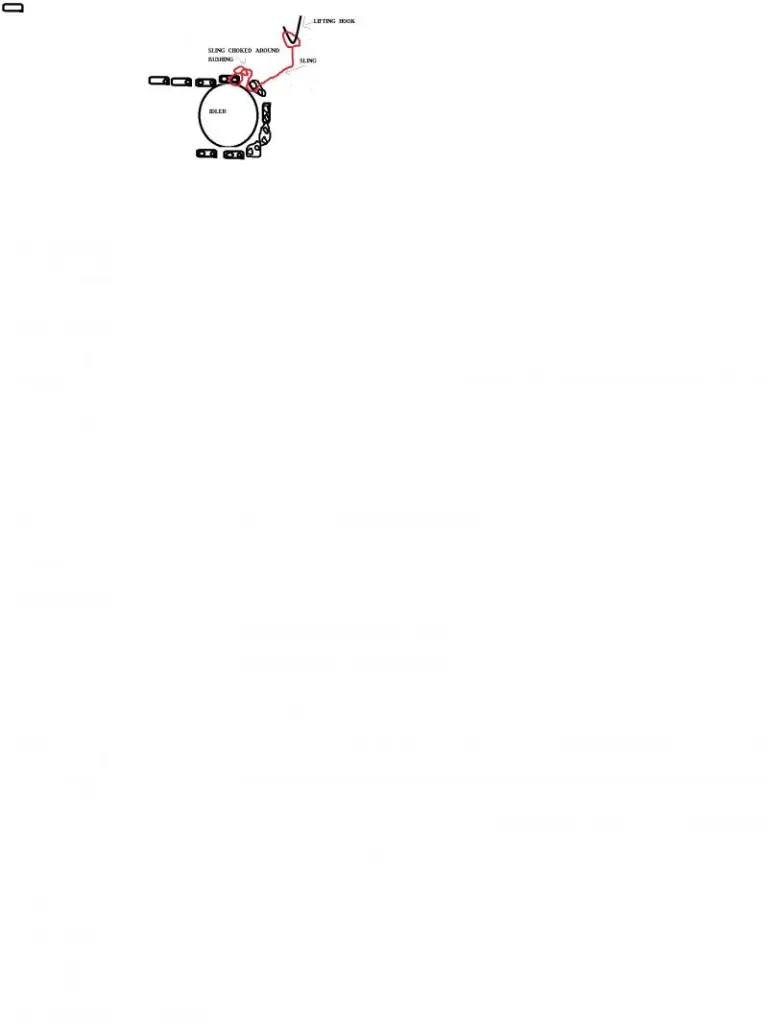

if you have overhead lifting devices (front end loader, forklift, overhead hoist, gin poles, chain falls etc) you can choke the bushing on the end link on top of the idler with a nylon hoisting strap, then put the strap between the links on the other end of the track. put a crowbar through the links and make sure the nylon strap is under the crowbar. lift the end of the strap that is hanging out and it will pull the links together on the idler it almost self aligns as the idler holds them from being majorly out of line, and you can make any minor adjustments using an alignment bar. then it is held in place while you drive the pin in.

if this description isn't clear, I can draw and scan in a picture of what I'm trying to say.

this is one of the safest ways I have found for putting tracks together when you don't have additional people.

[attachment=31573]track joining.jpg[/attachment]

Thanks. I think I understand and yes I do have a front end loader. Instead of using chains and D shackles on steel bars pushed through the links I should have thought to use a strap as you suggest.

Ian