Reply to SpragueM:

What is open and closed center? What advantages are there to each?

Thank you,

Matt

[QUOTE=SpragueM;43431]What is open and closed center? What advantages are there to each?

Open center hydraulics are arranged so that the pump flow circulates at all times through all the valves, perhaps free flow or can be against a pressure relief valve (arranged last in line of all the valves), so that it maintains a certain standby pressure and then on back to the tank. When any function (valve spool) is activated, it takes the flow away from all other valves which are in the hydraulic circuit after it. A second valve can be opened but will not get pressure oil if the first one is completely activated.

Partially open valves allow some bypass flow which can allow other functions to operate, but release the first one and suddenly the rate of the second increases suddenly! This is/was? common for backhoes and tends to catch the novice operator (me)😊 by surprise and cause a violent movement when a lever is returned to neutral while another has been held wide open, but receiving no flow!

The pumps are usually gear pumps. Relatively simple, robust, cheaper to manufacture, can be made to very high capacity quite easily, but can be a large parasitic load even while no hydraulic function is needed.

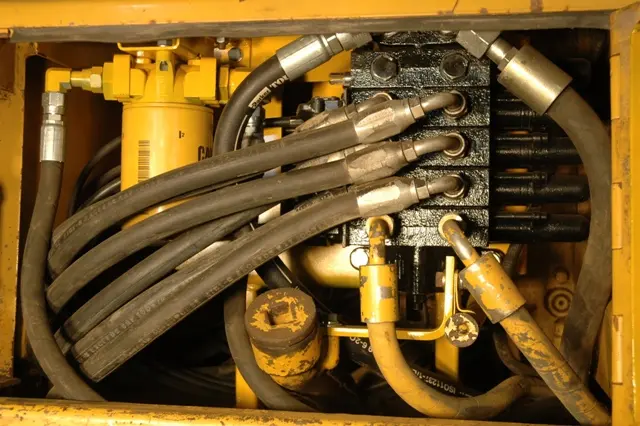

Closed center systems build up to operating pressure and then the pump goes into a standby mode (usually by destroking pistons) so that hydraulic flow is available at any valve which opens from the pressurized system. Functions (valves) are all equal priority unless some mechanism is put in place to prioritize certain ones like steering and brakes for example.

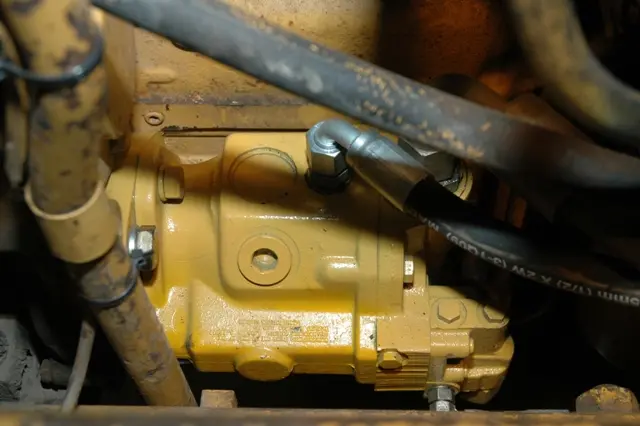

The closed center pump tends to be more complex and expensive, but is more efficient since once the pump builds up to standby pressure, it destrokes itself and cuts the load on the engine to almost nothing.

I am sure others can add to or correct parts of this.

With the correct equipment, open center hydraulics can operate laser guided equipment. We operate a tiling plow for example.

D2-5J's, D6-9U's, D318 and D333 power units, 12E-99E grader, 922B & 944A wheel loaders, D330C generator set, DW20 water tanker and a bunch of Jersey cows to take care of in my spare time😄