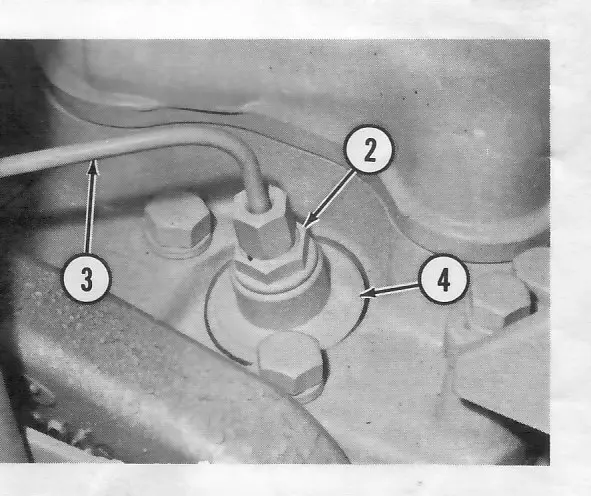

PC engine has a circular boss screwed in the head around the injector. (the top of the precombustion chamber) and there should be a glowplug threaded into it. The DI engine doesn't have the PC chamber, the injector should mount directly into the head.

Hi steve,welcome to the BB.

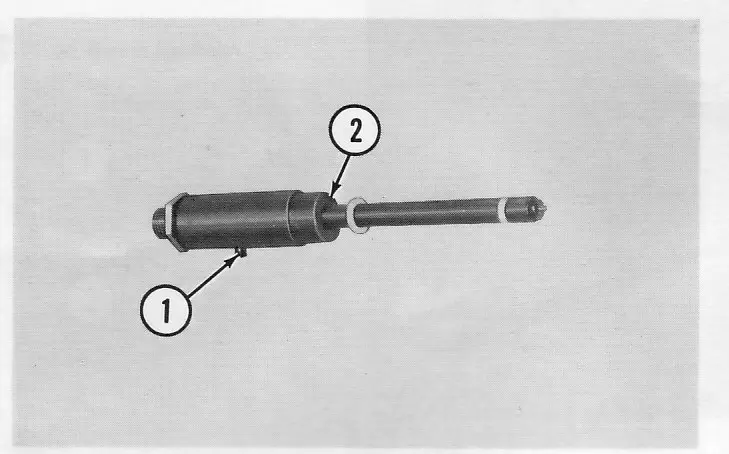

Just to add to what CCJ said the DI injector is known as a pencil injector by Cat.

The main body is about the diameter of a pencil , and the fuel injection line connected straight on top of the larger diameter top body.

As CCJ said it mounts direct into the head without any adaptors--see scan below for DI Nozzle and an example of a typical PC setup--- actually D330 D333. The 3304-6 are similar.

Hope this helps.

Cheers,

Eddie B.

[quote="edb"]Hi steve,welcome to the BB.

Just to add to what CCJ said the DI injector is known as a pencil injector by Cat.

The main body is about the diameter of a pencil , and the fuel injection line connected straight on top of the larger diameter top body.

As CCJ said it mounts direct into the head without any adaptors--see scan below for DI Nozzle and an example of a typical PC setup--- actually D330 D333. The 3304-6 are similar.

Hope this helps.

Cheers,

Eddie B.[/quote] O.k. thanks ! I replaced one nozzle { barreled shaped with a tapered end} because my #2 cylinder wasn't fireing. when I was doing that I went to put some tranny oil in there to see if I had stuck rings . When I inspected the hole I seen a piece of what looks like a valve stuck in the piston crown .

How I came about all this is there was raw fuel coming out of the exahust man. thats when I did all the above. I checked the oil, because my throttle would not worke, it was very low so I replenishd it and now the motor knocks like a SOB !

I'am going to pull and rebuild the motor . I have alot to learn about this stuff! But I have all the manuals and sit down and read them when time allows! I race and work on motorcycles and everything else so hopfully that will help my learnig curve.

Hold on here!

Lots of reasons for fuel slobber and a miss that don't involve an overhaul. Of course there are some that do require an overhaul to correct.

First, the thing that looks like a valve stuck in the piston is likely a "heat plug". CAT has used several designs of pistons over the years and that is one of them.

The easiest trouble shooting is to swap injectors from cylinder that is running good with one that isn't. Determine which are firing by loosening each injector line in turn with the engine idling. A good cylinder makes an audible change in the engine sounds when you cut it out. A bad one doesn't..

If the miss doesn't move with the injector, then you still have the pump to consider. You can take the injector line off of it and reinstall with the injector capsule screwed just hand tight on the "body" which is tightened onto the line sticking out away from the engine. If the capsule injector is finger tightened onto the body, it won't leak. Do not tighten with tools, the thread is designed to be loose, that's how the fuel gets into the injector capsule from the body!

Then decompress the engine if possible or loosen all the other injector lines so the engine cannot start. Turn the engine over with the pony or starter with the throttle open. BE CAREFUL not to get fuel injected into your fingers, Keep them away from the spray! If you don't get a fine even spray, swap an injector capsule from a 'good' cylinder or a new one onto the line and see if it improves the pattern. Poor pattern or dripping from a good injector probably means the pump is damaged and should be rebuilt or replaced.

If you have good spray pattern from the injector, but still a dead cylinder, the next step is to do a leak down test. You can take the injector hold down nut and adapt an air line into it to pressurize the cylinder with shop air or even from an air "pig". Use some teflon tape and screw the nut into the precombustion chamber of the cylinder you're testing. HAVE THROTTLE CLOSED, tractor in neutral, brake set, you can spin the engine and start it on the other cylinders if you are unlucky. The piston needs to be at exactly TDC and held there somehow. I like to take all the injector lines off in preparation to checking all the cylinders, then I can put the transmission in gear, lock the brake and engage the clutch to hold the engine. Use the timing marks on the flywheel for setting the piston at TDC. If air is rushing out the exhaust and intake, you're probably on the exhaust/intake stroke instead of compression stroke, so turn the engine 1 turn and come back to the mark on the flywheel.

There is a CAT way to do this and a 'shade tree' way. I do it just to hear where the air is going. The CAT setup uses an orifice and pressure gauge to measure the rate of leak down. Usually if the exhaust and intake are quiet, then you're looking at piston and rings which are both going to be taken care of with an overhaul. If leaking past a valve, then check valve clearances before taking the head off. CAT has had problems with exhaust valves dropping heads or pieces of the head, so that wouldn't be uncommon. Of course you could have a dropped valve head stuck in the piston, but in my mind that would be rare.

Good luck!

If it looks like a piece of valve imbeded in the piston it probably is along with your other symptoms. The 3304 engines did not use a heat plug in the piston. What is the actual s/n and engine number, should be 78Pxxxx if it is USA built.

X2.........The heat plug would be a complete circle like a valve with the stem punched through the piston toward the crankshaft.

Only other thing I can think of is a valve relief cutout which is milled into the top of the piston. Maybe you have two problems, broken valve and rod bearing out???????

One thing you can usually do to diagnose a bearing failure is drain a sample of oil from the oil pan and check for metal. A metallic sheen to the oil as you pour it into a container is enough, though you may see flakes of bearing material as well.

[quote="ccjersey"]X2.........The heat plug would be a complete circle like a valve with the stem punched through the piston toward the crankshaft.

Only other thing I can think of is a valve relief cutout which is milled into the top of the piston. Maybe you have two problems, broken valve and rod bearing out???????

One thing you can usually do to diagnose a bearing failure is drain a sample of oil from the oil pan and check for metal. A metallic sheen to the oil as you pour it into a container is enough, though you may see flakes of bearing material as well.[/quote] I have'nt disected the the oil filter yet! I have 2 problems Ilive in Connecticut ,USA and the machine is 200 miles away on my property in Up state New York USA. Everything tools etc. have to be transported !