What's the s/n? Scroll or Sleeve Metering pump?

Does it start better if you use the hand primer first, what is the ambient temperature and how long do you actually use the glow plugs?

Roger, have you checked to see if the fuel tank filler cap breather is blocked?

Next on the list is fuel line blockage. I often had problems with fine fluff from rags, rust, dirt, and other debris, blocking the 90° elbows in the fuel line.

Third is checking for fuel line corrosion. The steel fuel line is prone to corrosion where it runs close to the chassis and where dirt buildup is holding moisture in.

The corrosion will create pinholes in the fuel line, that don't leak very much (just a weep) - but the pinholes admit air to the fuel system, and create hard starting after being stopped for short time.

Regards. Ron.

Hi Roger,

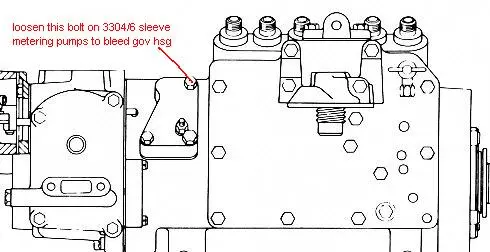

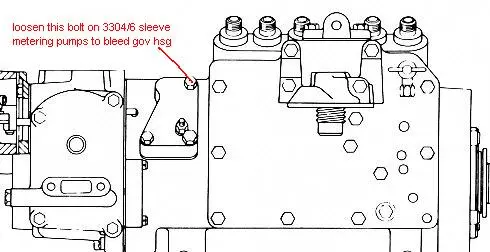

if this engine has the Sleeve Metering fuel injection pump--the one with the big side cover plate with many 1/4" bolts-- it will need bleeding at the governor housing --where the set point electrical connector is.

You need to loosen the top bolt on the odd shaped housing and get the gasket to release so that the gravity, or hand pump-- fuel pressure can force out air that becomes trapped in the Gov. Hsg.

This air builds up over time so much so that when cranking the transfer pump needs to pressurise/compress the air so the fuel level in the pump comes above the injection pump inlet ports so it can then inject and start the engine.

Cannot recall if the D6 has a return orifice check valve fitting that returns some 9 GPH of fuel/air back to the tank--I feel they do not but I mention it if so fitted to check for blockage.

Attachment below should help.

Cheers,

Eddie B.

If it is sleeve metering it probably has a constant bleed valve that edb mentions. Normally only flows when fuel pressure in housing is 25 to 32 psi.

If it leaks it will drain off the pressure which will have to be re-established on start.

The bleed valve is built in to the elbow fitting coming off the pump with the line going back to the fuel tank.

Replace the batteries ,it takes 2-3 minutes of glow plug heating at those temp. to lite off fuel and the faster the motor spins the better it will start.Are you using a 10w30 or 15w40 oil? PC engines are always hard starting in cold weather.

Bob

If it's like the sleeve metering setup on my 10K there isn't any return line to the fuel tank.

If it is sleeve metering it probably has a constant bleed valve that edb mentions. Normally only flows when fuel pressure in housing is 25 to 32 psi.

If it leaks it will drain off the pressure which will have to be re-established on start.

The bleed valve is built in to the elbow fitting coming off the pump with the line going back to the fuel tank.