[quote="kittyman1 post=237466 userid=13667"]-is it necessary to replace glow plugs before they fail? as routine maintenance?

-do they have a lifespan? depending on use, number of starts? or just randomly fail?

-best before date? etc..

-if they have resistance measured with an ohmmeter, is that good enough? or should it meet a certain level?

-just wondering..[/quote]

Probably depends on your definition of necessary. I haven't seen any service manuals for any of the brands I've been into that talk about pre-emptively replacing glowplugs that still work. That said, if you "have the hood off", sometimes it's convenient to replace them all if one or two fail. I've had "random" glowplug failures, some after just a couple of years, and some after decades. Manufacturers often specify the acceptable resistance range for glowplugs

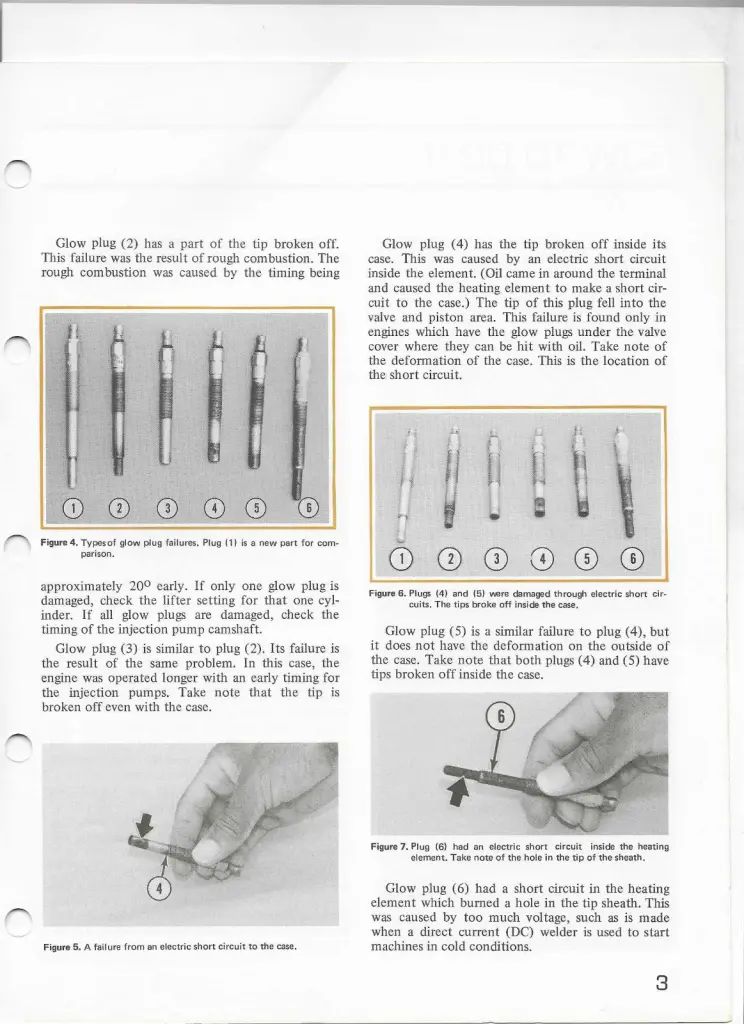

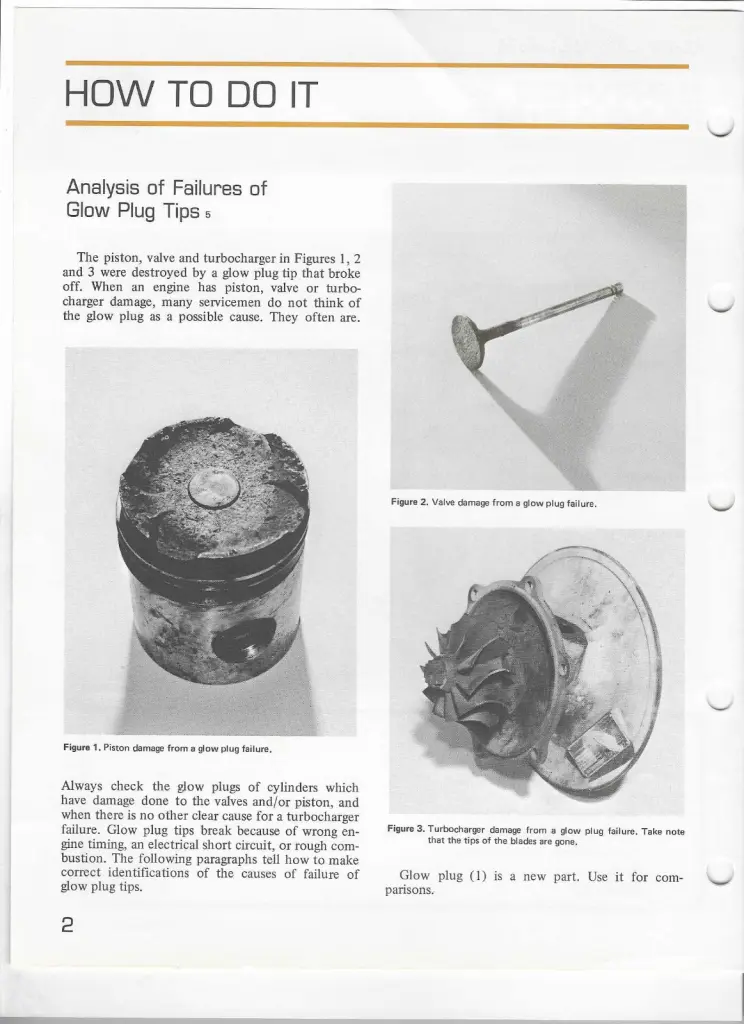

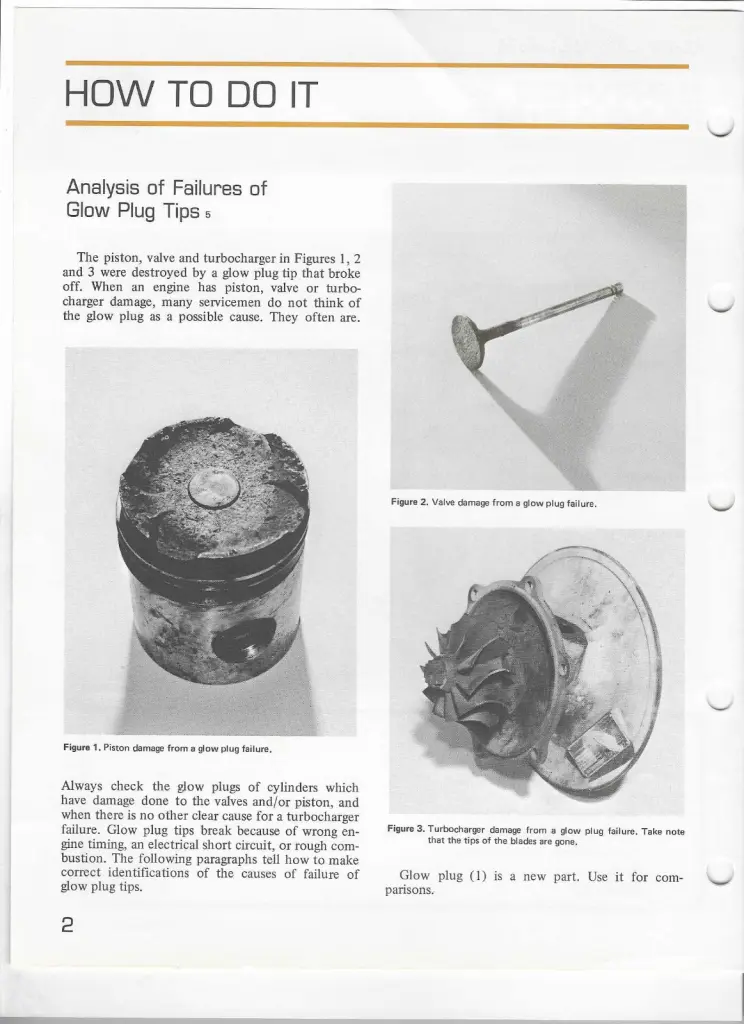

Here are some signs of damage.. [attachment=67495]Cat Glow Plugs 001.jpg[/attachment][attachment=67496]Cat Glow Plugs #2 001.jpg[/attachment]

We always replaced them when reconditioning the head or around 10-12,000 service hours. We would inspect them at every 2000 hrs when adjusting valve tappet clearance.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

a point to remember when checking the resistance, it should be read quickly ie a few seconds not half a minute. as resistance changes with temperature. also you dont want to burn out your multimeter. also buy quality units they last better. a light dab of grease or copper anti-seize on the thread will aid install and future replacement.

There is an inch lb torque rating for glow plugs also, check in your engine service manual. 120+-24 INCH lbs for plugs on 3304,6 engines

My experience with glow plugs has been more extensive and expensive with Ford 7.3 IDI engines than "cold blooded Cat motors" as my Pap would call them, but I expect it's all similar. An engine will crank fine with them until it doesn't. Then one or all may be foul. Good steady voltage and clean tight connections are never a bad thing. And good quality replacements are sometimes a bargain at twice the price. Anyone who has been lucky enough to wiggle a Autocraft, Beru, insert generic part name here plug with a swollen tip out of those old IDI engines will probably argree with me. Also, some of the better manufacturers will give you resistance specs that their parts should fit.

a point to remember when checking the resistance, it should be read quickly ie a few seconds not half a minute. as resistance changes with temperature. also you dont want to burn out your multimeter. also buy quality units they last better. a light dab of grease or copper anti-seize on the thread will aid install and future replacement.

[quote="trainzkid88 post=237486 userid=11838"]a point to remember when checking the resistance, it should be read quickly ie a few seconds not half a minute. as resistance changes with temperature. also you dont want to burn out your multimeter. also buy quality units they last better. a light dab of grease or copper anti-seize on the thread will aid install and future replacement.

[/quote]

Never heard of burning out a multimeter checking resistance for too long. You will do damage if you test resistance in a powered circuit. Most multimeters only put a small voltage through the circuit to test resistance and it shouldn't be enough to cause a glow plug to even get hot.

In the past I have connected alligator clips to my multimeter test leads and left them connected checking resistance for up to an hour with no side effects.

Agree with the comment about a quality meter though. I learned that in Auto TAFE and only use Fluke.

In regards to the thread questions; personally I think you would be throwing away perfectly good glow plugs if you replace them periodically. If you have an amp meter installed you can then tell when they are not working.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality