Reply to chriscokid:

[quote="Old_n_slo"]It ok though.....I am interested in the solution too. I'm torn between wanting to correct the problem, but not wanting to open up a can of worms.

Does yours leak during operation? Idle? Shut down?[/quote]

Yes it leaks when it is running, when it is shut down it only drips very slowly. I believe I just need to remove the whole thing and go thru it all. This machine has 10,000+ hours on it. It has been in my family since new in 1940.

I hope you get yours fixed and if you do please share what you will learn!

Hi Team,

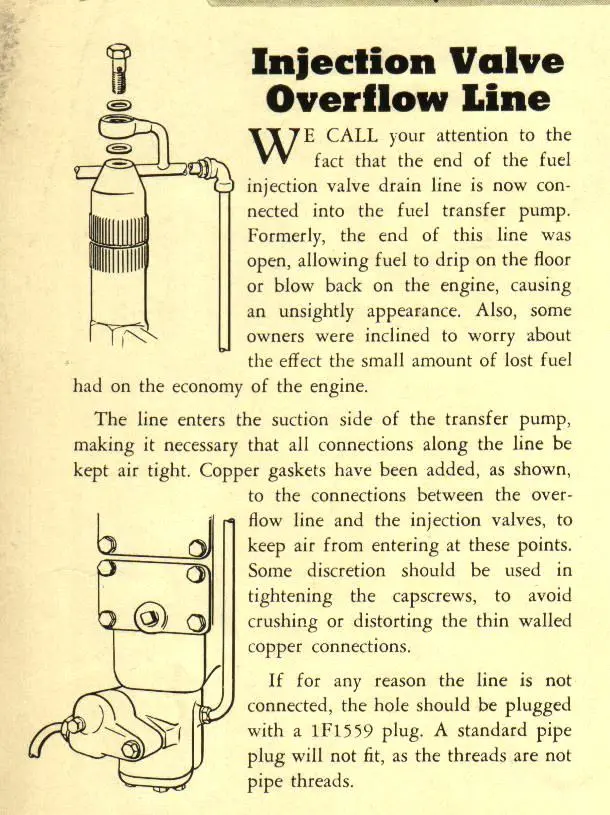

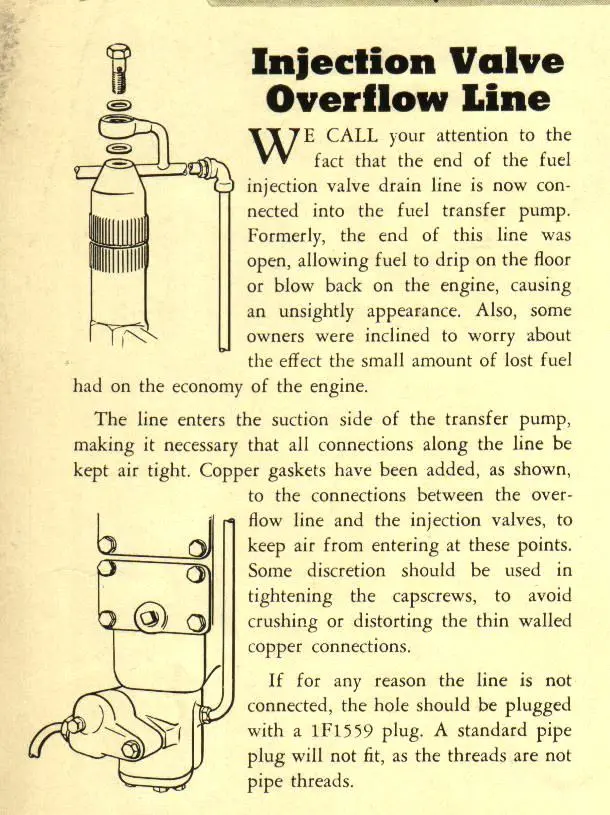

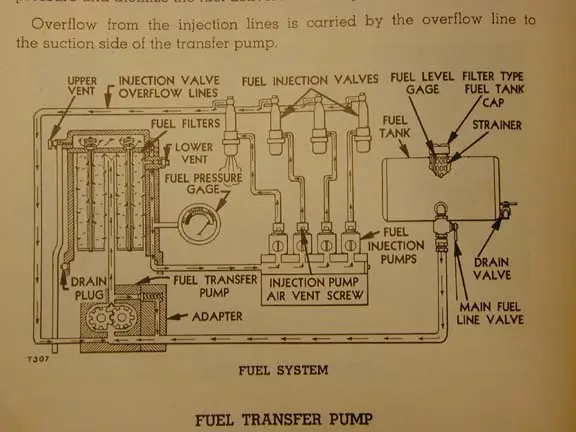

from memory the 2 lines drain to ground on the earlier S/No machines. As stated above, on later units the injector drains were connected to the transfer pump inlet.

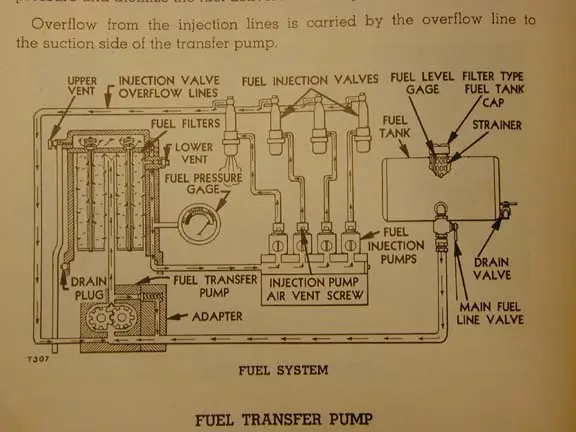

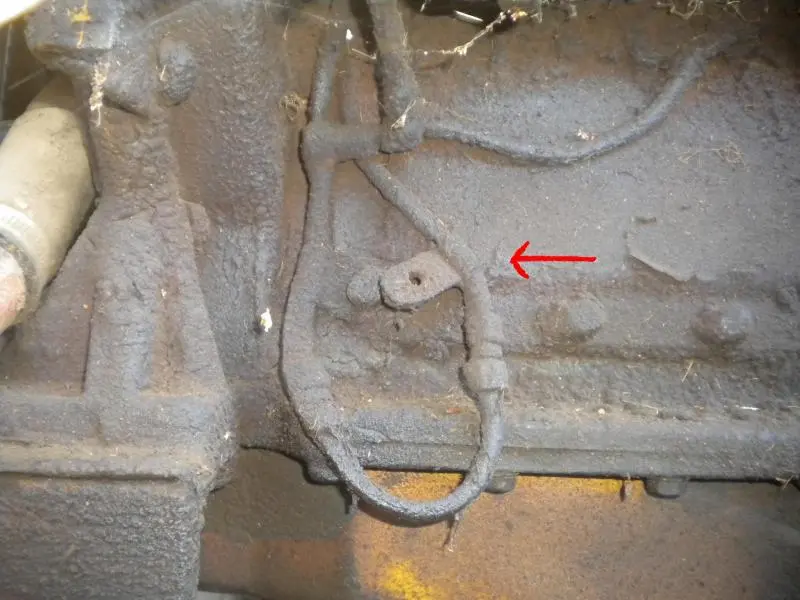

The other lines come from :-

1/ the tower bleed screw.

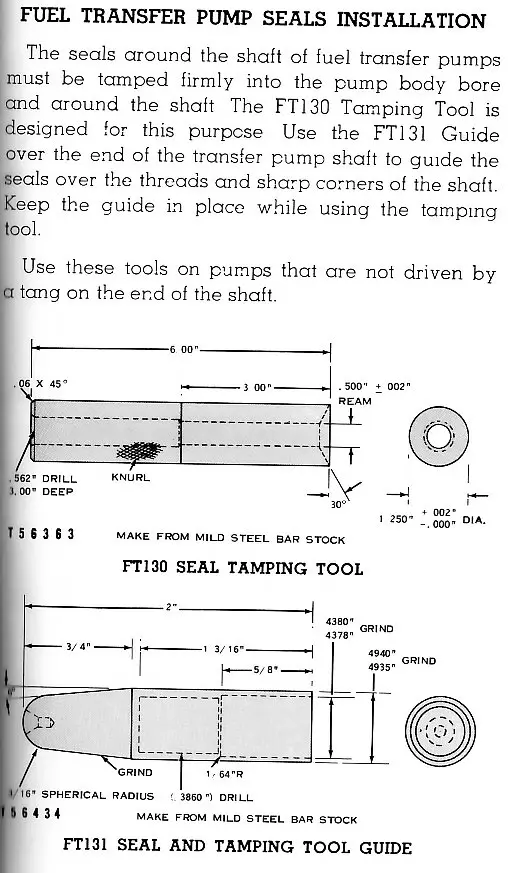

2/ another comes from the transfer pump packing cavity to drain any fuel from the pump fuel side packing or oil from the engine side packing. If this line is blocked or subject to transfer pump pressure, fuel can be forced into the crankcase if the oil packing is also leaking. The packings and shaft usually wear and harden over the years and the compression spring can no longer crush the packing in its taper to keep the packing fuel tight.

3/ another drains the rack area of the injection pump. This drains off fuel seeping past the pump plungers.

If this area is not drained or is connected to gravity fuel pressure from the fuel tank head height, this area will flood the injection pump housing and dilute the oil therein and cause excessive wear from oil/fuel dilution.

The lines from 1, 2 & 3 above are teed together.

To sum up the only line that can be connected back into the system is the injector drain line as per the scan below.

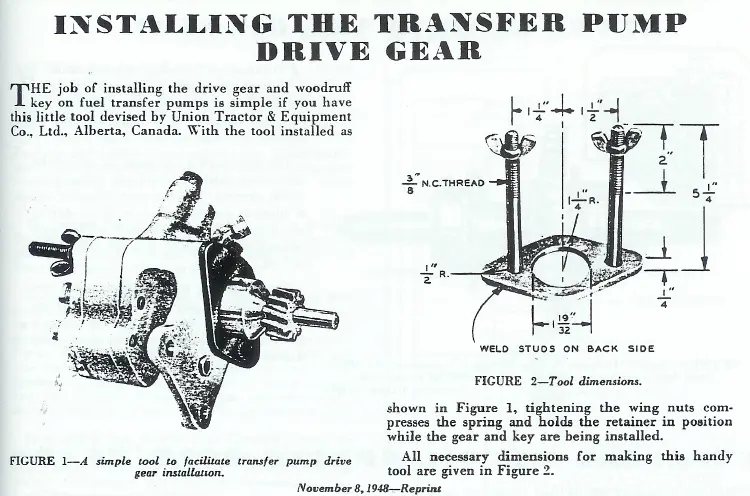

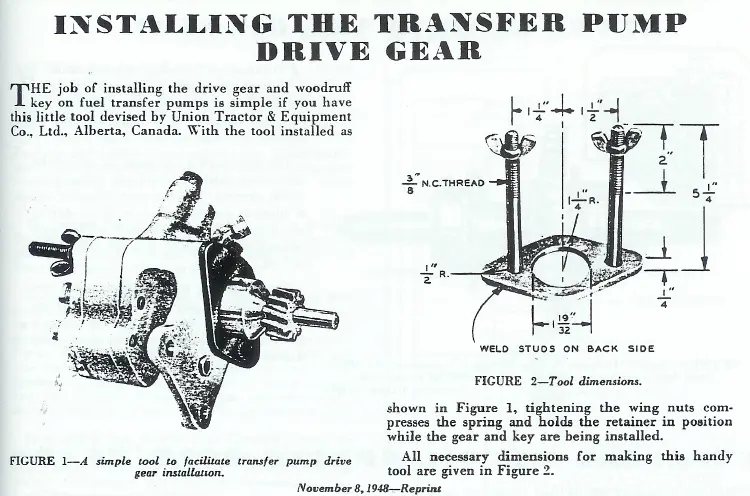

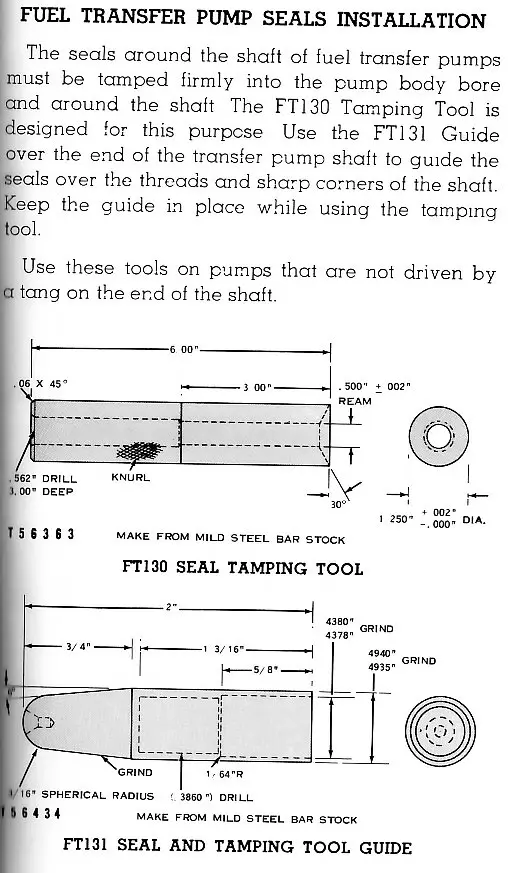

The others all need to be open to drain on the ground. If you have leaks from the teed lines then you will have to disconnect the teed lines to determine which area is leaking. It is most likely the transfer pump packings that will need to be renewed and tamped to give a good seal in their tapers. Use Search to find drawings for the tooling and descriptions of the transfer pump overhaul.

If the transfer pump packing is OK then I have seen many tower bleed screws that leaked from having been overtightened or crud on their seats.

Hope this helps.

Cheers,

Eddie B.