Hello cab, ya it should vent. Sounds like it may be the transfer pump seals. Pretty easy to take apart and fix.

Gary

Fuel leaking past the transfer pump seals would show up in the tell tale drain line. The most likely source of leakage is the o-ring seal between the governor housing and the injection pump housing. Same 8B4967 o-ring (-31😎 and ferrule that they all use.

Your right mag, it does have a drain line. Thought that was making the pressure in the tank. Wouldnt have good fuel pressure on the gauge if the relief spring was bad or not seating.

Hi Cab,

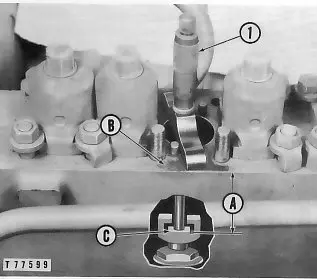

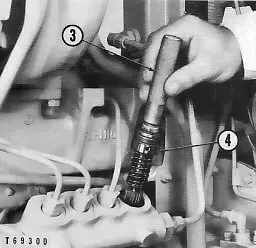

we may need a Serial Number so as to know what injection pump is fitted--later units have a compact style pump and not the forged body type, so we can give a definitive answer. Scans below show a Forged Body Pump and a Compact Style pump--D8H is similar but is squarer where the fuel gallery is.

A tank that is pressurised puts undue pressure into the fuel gallery which keeps pressure on the injection pumps plunger and barrel clearances--although minute-- and leakage past these will show after time--especially on the compact pumps as there is no rack cavity drain as on the forged body pumps.

If the transfer pump drain line is blocked and the fuel seal is faulty, along with the pressurised tank you found, then the fuel can be forced across thru the transfer pump seals into the engine. Usual suspects for blocked drain line is mud buildup in the belly guards, or mud daubers.

Also check the drain line from the rack cavity--behind the side plate--to see if it is blocked also.

I have not encountered one way breathing fuel caps--always open to learning something new. Only alternate style attachment or cap is those for fast fill systems but I doubt they are one way either--maybe if one of these is fitted the drain/breather plastic hose is crimped over or sitting in crud under the fuel tank especially if the fast fill is not used.

Cheers,

Eddie B.

It is definitely the earlier, larger forged body. I will check drains before going straight to o-ring.

Cap is the fiberglass/aluminum unit made to accept a padlock. It is a Cat product but may have been used in later machines that had an integral tank vent. Will be easy enough to gut the check valve and make it vent. Wondering if I should do that and see if it is still leaking before digging further.

As far as I know, all Cat fuel caps are vented with a metal filter inside them, if it is not venting both ways, it is clogged with dust.

Couldn't hurt to vent the Cap, maybe cheaper than tearing into the tractor looking for a bad seal!

Good logic would be to change a 25 cent o-ring seal along with some gaskets when this is a known failure item after 40-50 years rather than risk a main engine bearing failure.

Knowing cab, he's probably already got the work in progress.

Here are some pics of the mysterious 1 way cap that allows air into tank but keeps the tank from expelling any built up pressure. I gutted the check which is the yellow circular item in last pic and reassembled. After draining umpteen gallons of diesel/oil mixture out of crankcase until it stopped dripping out, I opened cutoff valve below fuel tank and sat and waited with drain plug out of oil pan. Sure enough, a faint stream of diesel started dripping out. OM, you are correct, I am already in progress on the teardown for o-ring replacement. Guess my fear of disappointing you outweighs my laziness! In all honesty, I like to logically work through things in my mind so that I understand where I am before I start turning nuts, but as usual you were right again.