"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

look at the end of the thread it will show you. if your talking about the nut thats behind the outer cover. it needs tightening to 1200 ft/lb when you reassemble the rough rule is 6 ft of pipe on your inch drive breaker bar and to average size blokes and swing on it.

from memory to undo you turn it to the blade if your on the left side according to the seat.

Both the hex nut on the very end of the dead axle and the large grooved bearing retaining nut are standard right hand threads on both sides of the machine. At least they are on my D6, D8 and 955K.

TK where do you get your information? 1200 ft/lbs on the bearing retaining nut? That sounds a little high and your method of tensioning it ain't gonna cut it.

look at the end of the thread it will show you. if your talking about the nut thats behind the outer cover. it needs tightening to 1200 ft/lb when you reassemble the rough rule is 6 ft of pipe on your inch drive breaker bar and to average size blokes and swing on it.

from memory to undo you turn it to the blade if your on the left side according to the seat.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

from my understanding you have unwind the bearing adjuster and that allows access to the bearing and sprocket. after removing the outer cover and the outer nut.

there is a clamp bolt in that adjuster nut that needs to be undone too.

Trainzkid88 could you shoot me a picture of where this clamp bolt. A picture would be most helpful to understand. Thank you gwoods

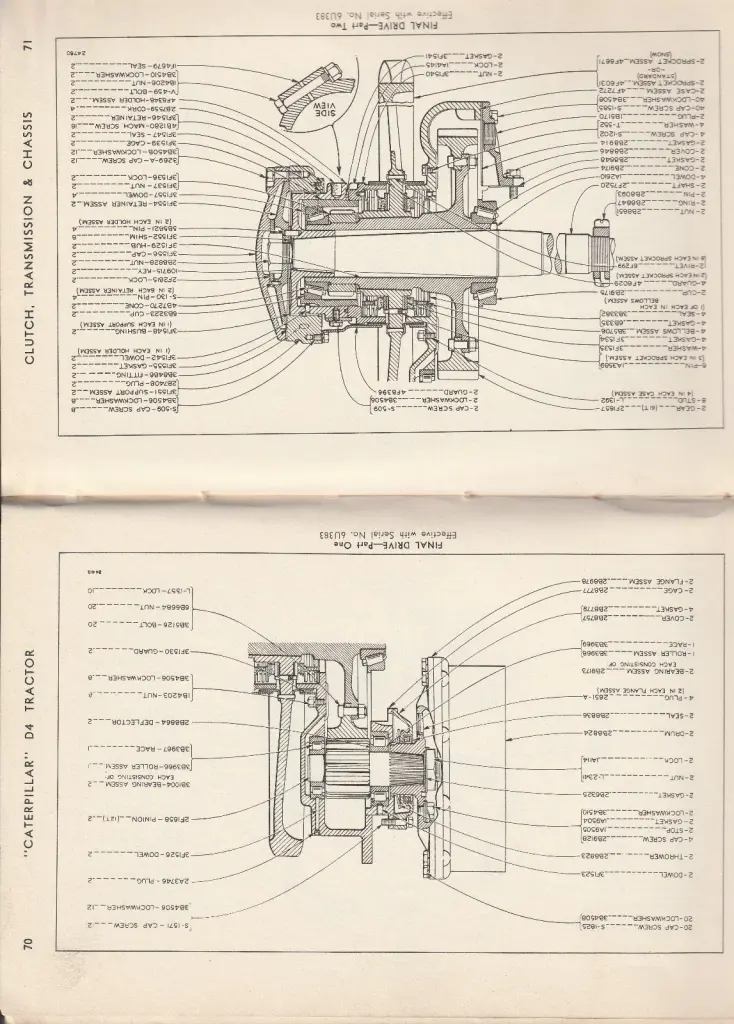

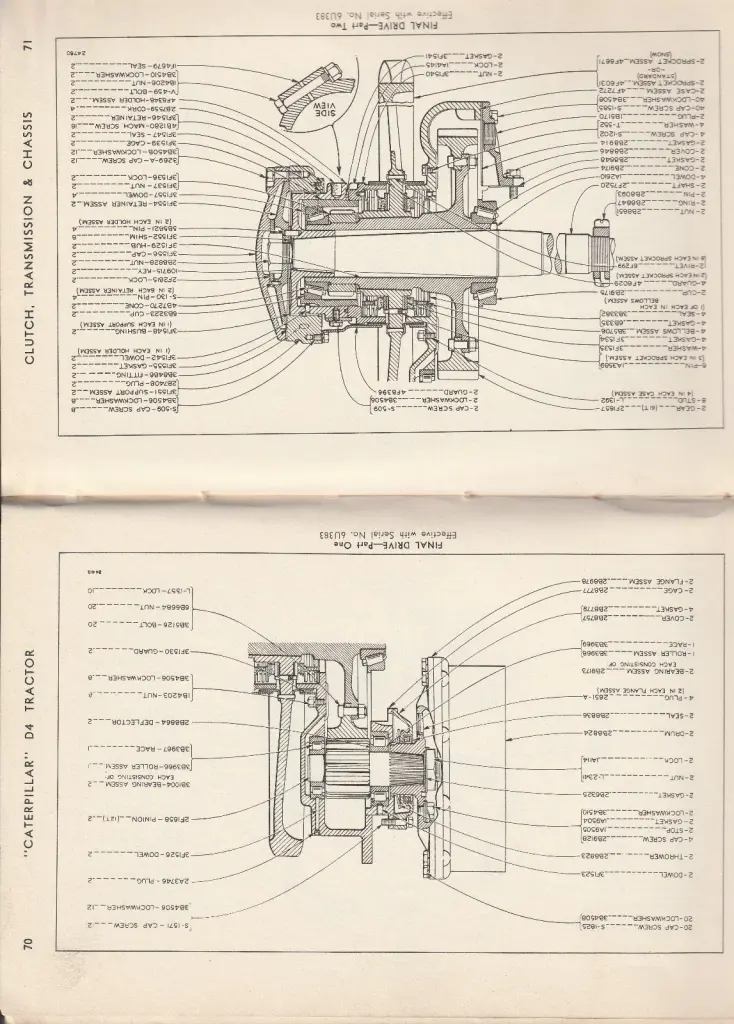

The avalable manuals and parts books are your best friends!

Get to know them before you do something you may regret.

Some service/repair operations demand special care and tooling. Pressures to remove bearings, sprockets, pins/bushings are extreme and may be life changing events!

Don't take shortcuts, improvise tooling, etc.

CTS

You have a wonderful day. Best wishes. Deas Plant.

Hi, gwoods.

This may help.

https://ww2-secure.justanswer.com/uploads/DIRTWRENCH/2011-02-07_042944_d4d_sprocket.pdf

Or this:

https://www.youtube.com/watch?v=hBUMKNfRxe8

There were a couple of related videos on the same page as that link when I looked.

Just my 0.02.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

[attachment=72525]IMG_20230605_0002.jpg[/attachment] the nut i was talking about is under the outer cover.the clamp bolt is part of the adjuster for the sprocket bearingsyou remove it so you can adjust the bearings

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality