Hi Team,

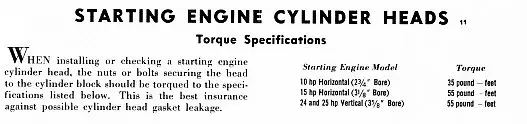

as the vertical pony engines are basically 2 cylinders of the above units I have the scanned specs below for the 7/16" stud/nut size at 55 lbs/ft.

A Spec sheet for later ponies with 1/2" stud/nut size lists the torque at 67lb/ft.

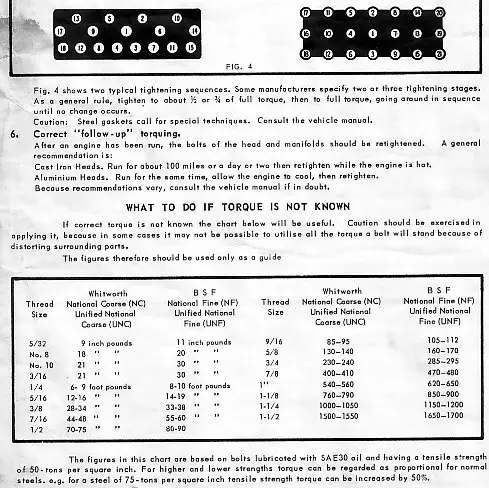

Yes, if the torquing pattern is not given then spiral out from the center in 3 steps is a good safe pattern to use.

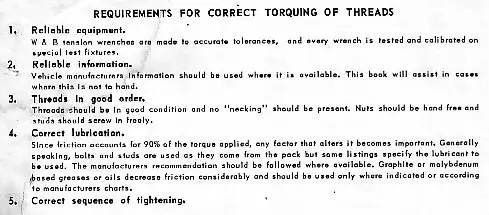

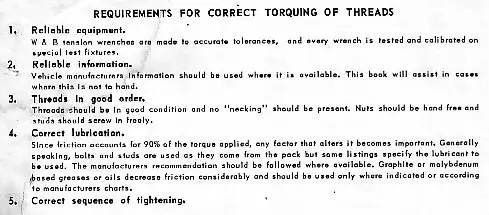

The other scans below are from a Torque Wrench hand book and give good pointers for achieving correct even torque.

Hope this helps.

Cheers,

Eddie B.

just had the headgasket renewed on my 15,

what edb wrote is perfect (and on the pictures there is written: nuts must go on easy with hand), thats what i didto arrage that : all nuts i screwed on to all studs with the air gun a few times on and off, and lubed it with wd40 to arrange that the run easy.

and at Olsons gaskets they said to torque a first sequence when installed, a 2nd torque sequence after engine has run a while so when hot and cooled again , and then a 3rd sequence after a couple of hours running and cooled down,

They hould not torque on third try very much. If it does-check your studs/nuts.

i did the 1/2" studs / nuts on 81 pound/feet , but a few nuts i had to trow away they were to worn and were not getting to the right torque they turned loose.

75 p/f could be used aswell, start with a 55 round then 65 and at last 75 p/f .

Hope this helps

just had the headgasket renewed on my 15,

what edb wrote is perfect (and on the pictures there is written: nuts must go on easy with hand), thats what i didto arrage that : all nuts i screwed on to all studs with the air gun a few times on and off, and lubed it with wd40 to arrange that the run easy.

and at Olsons gaskets they said to torque a first sequence when installed, a 2nd torque sequence after engine has run a while so when hot and cooled again , and then a 3rd sequence after a couple of hours running and cooled down,

They hould not torque on third try very much. If it does-check your studs/nuts.

i did the 1/2" studs / nuts on 81 pound/feet , but a few nuts i had to trow away they were to worn and were not getting to the right torque they turned loose.

75 p/f could be used aswell, start with a 55 round then 65 and at last 75 p/f .

Hope this helps