Hi kittylover123,

you could start by servicing the detent unit--it is the round housing on the cross shaft assembly that from memory mounts across the rear of the engine--the device that the link assembly, shock absorber looking device-- connects from to the Injection Pump Control lever.

There are springs and rollers in there that get dry over time--clean and re-grease.

The inner and outer--double-- shafts of the cross shaft assembly can get tight from being dry too--dry moly-lube spray is good so dust goes not gum things up but may need to be dismantled to clean out.

From memory they were fairly firm in operation when new--some dry moly-lube in the link assembly may help too.

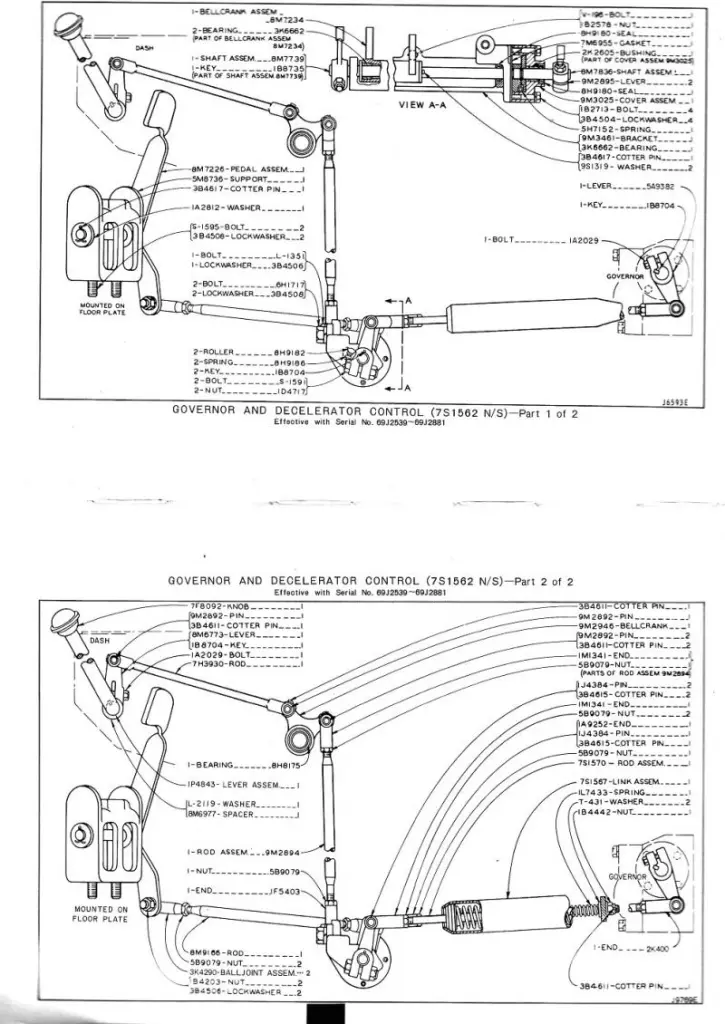

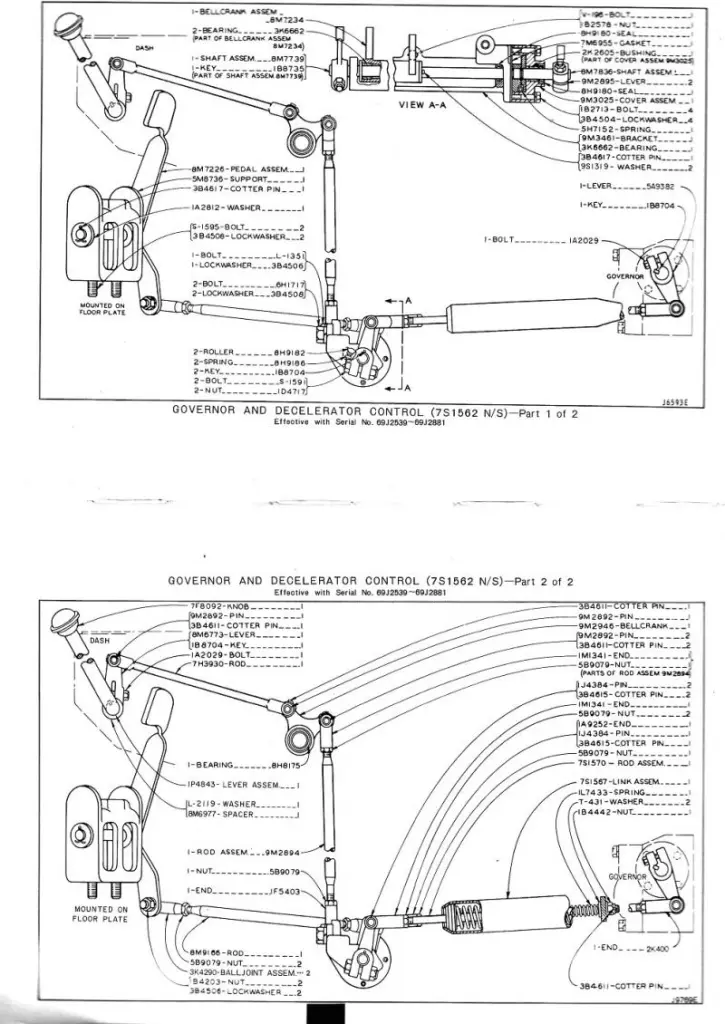

The scans are from my Japanese D6C Parts Book so may be different in some fine respects but should be similar to your unit I feel.

Hope this helps.

Cheers,

Eddie B.

yes thanks for the info Ed:first:

-those scans are very similar to my parts book, mine is actually for Early 10K series, very similar unit and time frame...

-the problem is not in any of the linkage or pivots points, it in the shock absorber looking housing itself...the housing is approx 1.5" outside diameter, has a spring fits inside, about 1.25" diameter, perfect. but the length of the tubing inside is 7.5", the spring relaxed is 10.5" long, no wonder it's so difficult to compress:crazy:

-i cut the tubing and removed the spring, cut 2.5" off it, replaced the spring and welded the tube up with some small 6013 rod...now it takes 5-10 pounds to compress instead of me standing on the pedal...damm that was annoying:baby:

now that is a very ingenious modification--I too recall how hard some of the decelerators were to operate and was glad I did not have to operate them all day long.

Thanks for the feed back--something else to store away in the grey matter file.

Cheers,

Eddie B.

it's very simple to do and makes your operating so much easier...it makes me wonder if this is a common problem with machines so equipped with a decelerator?

-when you're running a standard shift machine especially, you're doing about 5 things at once and it's hard to develop a rhythm when so much pressure is required...

-you can cut the spring in small increments until you get your desired pressure, and if you cut too much no problem, you can add shims to increase pressure...so you can't really go wrong

- and if you're still hesistant, just tack weld the tube, reinstall and operate before completing the weld...

-and on the other rod to the pedal linkage, you can adjust to get your preferred pedal position...at idle or at load RPM..

Win..Win😉