D7-3T; When I had my final drives apart I took hold of the pinion shaft and checked it for play,, it had a little too much up and down and when I turned it there was some play there too.

Well being a green horn to this machine i just took note.

When I tore down the other side I checked it and it was tight, so I figured when I finished every thing else I could adress it later. So i closed my eyes and ran it any way.

Didnt make it through the testing ground ,I guess it made about 10 hours when the clutch onthe right side started pulling in hard then on a slow engaugment it started chattering.

I pulled the cover took a temp reading 320 f left side was 120 .Stucck a bar inside a pryed on the clutch 1/2 up and down. Time to tear into it.

Tore it down today, pinion flange bolt loose , splines flange and shaft bad shape , I want to work it so I will replace them.

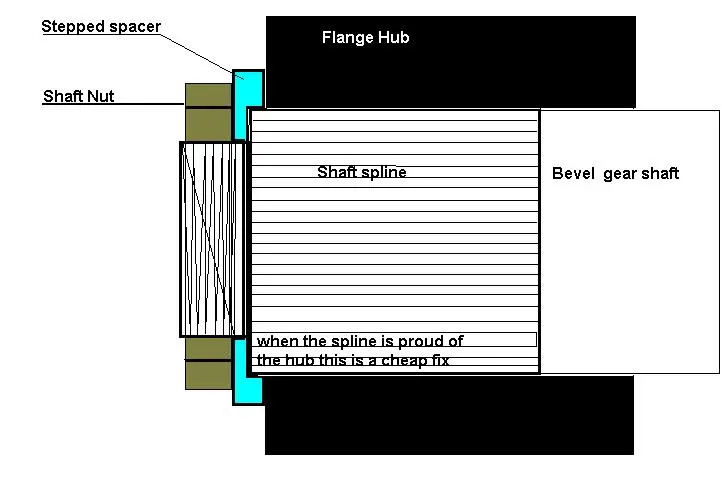

The other flange has play but the bolt is tight the washer is bottomed out on the shaft so it wont tighten any further.

My question is ,do you think a new flange will fix this, the spline on the bevel gear shaft looks fair.

If not its either improvise or new bevel gear shaft,I hope not.

I dont want to tear my finals apart again , what do you think will happen if I have a new bearing on only one side of the final drive pinion shaft?

I really dont want to tear off the final drive again. It was said that that type off roller bearing is forgiving as far as tolerences go. Thanks