I don't know about the D9's but I think the D8 torque convertor drive has a longer chassis compared to the direct drive.

The case and engine frame assembly according to parts book and NPR are different for 18A and 19A. No clue what specific differences are. If 19A is longer would not be impossible to convert, would need longer drive shaft from clutch to transmission. Unless there is something that would make oil clutch interfere with something in frame design.

Hi Clayton, if it worked out, would this tractor have a clutch and a 3-speed powershift? Reason I ask is that the D8LSA is almost that. It has an hydraulically-operated two-speed clutch (direct and underdrive) coupled to the 3-speed powershift, giving it 6 speeds forward and reverse. The other thing is that if you did manage to build it, that would give an option to other 19As that need unavailable torque convertor parts (I don't know if parts are available, but if they aren't, this would be a potential lifeline for those tractors)

Hi Neil yes Brian18a is correct it would not have any sort of power shift to it. The under carriage is in great shape actually the entire machine is in great shape except for the torque converter being bad .

Hi Neil yes Brian18a is correct it would not have any sort of power shift to it. The under carriage is in great shape actually the entire machine is in great shape except for the torque converter being bad .

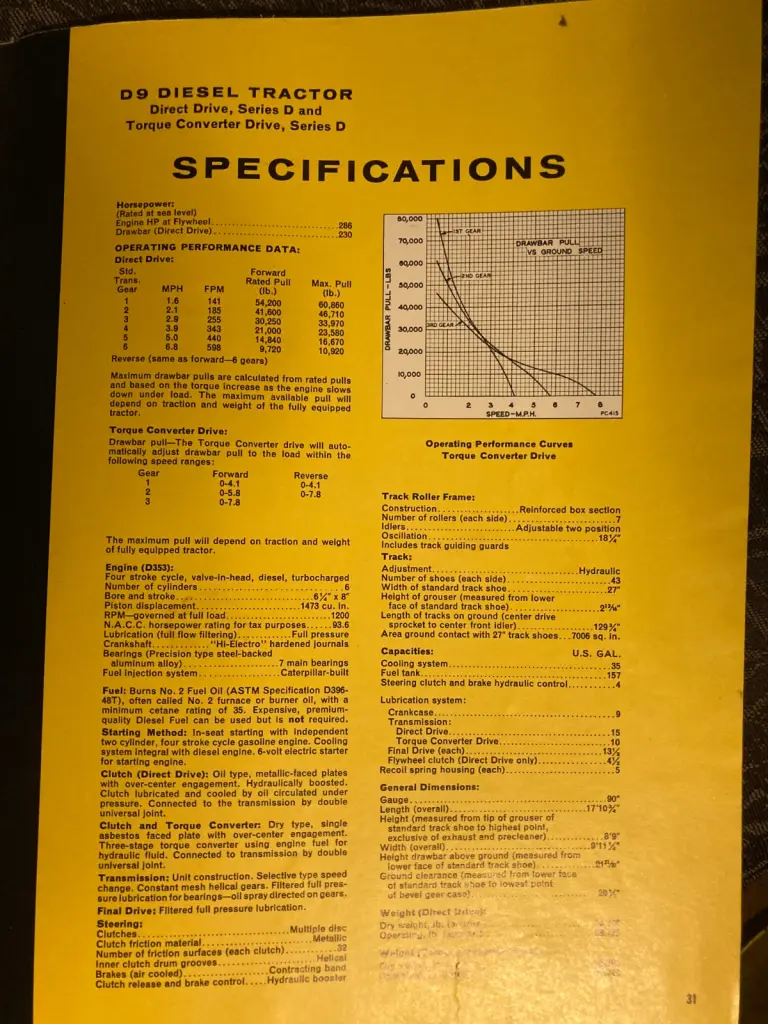

Wobat it’s too good of a tractor to go to the scrap yard but I have been unsuccessful at finding a used torque converter and was trying to find other options to make it operational again. So if I were to make it direct drive is the gear ratio in the transmission difference in a 18A versus a 19A or is the torque converter somehow slowing the output shaft down?