Reply to Oil Slick:

blackkw, sounds like a lot of work ahead of you. The deeper you got to tear into it, the more I would be willing to pay the extra amount from cat to make sure it's a top quality replacement part. Defiantly don't want to do it again.

Hi Blackkw,

alas, there are many parts that would be damaged by the small pieces of the hardened and crushed up Planet Gear bearing rollers. The entire trans. and TC will need to dismantled and inspected closely to determine what needs replacing.

For a start you will be up for all bearings and seals.

There will be planetary shafts and gears--usually these fail in Fwd and First as these are the most used range and gear.

There will be sun gears and maybe a ring gear or two.

Some clutch plates can be swapped between Fwd and 3rd. Rev pack uses larger inner diameter discs/plates than the other packs.

Hopefully the trans has had an easy life and the planet carrier shaft bores are OK.

Some clutch pack piston seal rings--cast iron--will be worn and the most used clutches again will likely need to be machined Over Size and oversized rings fitted to correct wear steps and grooving from the hard bearing metal pieces--have been known to bronze up the tip of one side of the ring gap--use a pencil lead or similar to stop the tension spring drilling being closed up by the bronze and file gap to (from memory) 0.005" to 0.010"

Be sure to run a blunt fine file around the sharp edges of all piston ring seals to remove the sharp edge which invariably catches when trying to assemble the parts and causes ring breakage. Also this chamfer allows the rings to work past wear steps and/or depressions left that polishing may not have totally removed after polishing the running surfaces, this helps stop putting undue side loads on the ring grooves etc.

The valve packs should survive if not already worn from many hours use with dirty oil. These will need to be dismantled, cleaned and inspected for erosion from dirty oil at all the sharp land corners of both the valve spools and the body ports.

In the TC there will be bearings, bushes (in the center of the input flange) and seal rings and their replaceable carriers and retainers--one is the scavange pump drive gear.

The TC main shaft, from memory has a ring groove that is machined into the shaft--if so, the groove can be machined to take two rings by machining the groove a bit from each sidewall of the groove.

The TC impellers can crack at the junction of the vanes to the inner vortex ring and/or to the outer cover and also at the mounting pad for the scav pump drive gear--they can frett here too.

The turbine hub splines wear but can tolerate some wear and fretting--be sure to center punch the shaft and the turbine to enable reassembly in the same splines.

The stator vanes are swaged into the inner and outer rings and do come loose and wear causing inefficiency--if only one or two are loose we have welded the swaged areas after setting the vane to the correct angle with a suitably made spacer to fit between the vanes and hold them at the correct spacing and angle.

The good book gives the clearances for the labyrinth seals between the impeller, stator and turbine NOTE these are half of the actual running clearance,ie, radial clearance and from experience the diametral clearance can be larger than the maximum permissable by about 0.010"-0.015" without causing overheating or power loss.

Man this is going back some 20 years since I worked on one of these.

The Torque Divider Planetary on the TC Input flange and output shaft will need new planet gears shafts and bearings--be sure to dig the crud from all the inside surfaces of the Main converter housing, the flywheel splines that drive the converter, the ring gear teeth of the divider ring gear--in fact anywhere that centrifical force can catch metal and dirt within the rotating pieces--clean oil dislodges some of this and starts the failure process again after the filters block.

Clean out the pockets in the flywheel housing at the mounting cavities inside the flywheel housing--may need to remove the flywheel to do this.

The TC scavange pump--in the bottom of the TC main housing--remove this pump before and refit after the TC is removed and refitted--bent drive shafts result.

The Trans/Steering pump--at the front top right of the flywheel housing will need at least new white metal bearings and seals. Grind 0.020" off the end of the trans pump drive shaft to stop end pressure from worn drive splines--This especially if a new pump is fitted--saw many new pumps seized by excessive end pressure from wear steps in the pump drive gear in the back of the engine.

Remember to pour at least 2 gallons of oil into the flywheel housing before startup for the TC scavange pump to pump until the TC fills and leaks enough oil for the pump to pickup and survive!!!!

Also the steering valve, brake booster pistons and all lines, screens, and filters will need to be removed dismantled and flushed out to remove the metal.

In fact anywhere that uses the Trans systems oil needs to be dismantled and cleaned out--this is a big job make no mistake--if you short cut it you will surely be back into it again.

You will be up for a new or warranted flushed used Trans Oil Cooler Core too.

Have likely missed some things but this should get you going and initially answer your query in part at least--sorry never good news when thes things fail it is always big Dollars.

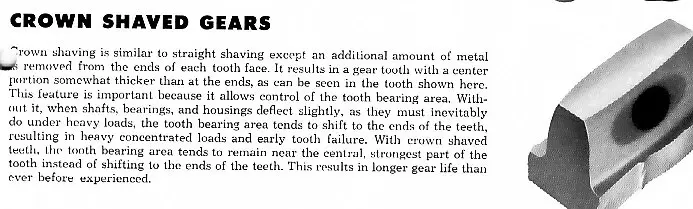

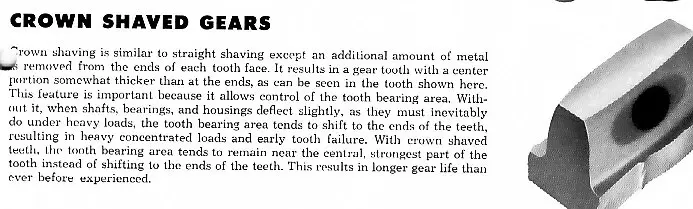

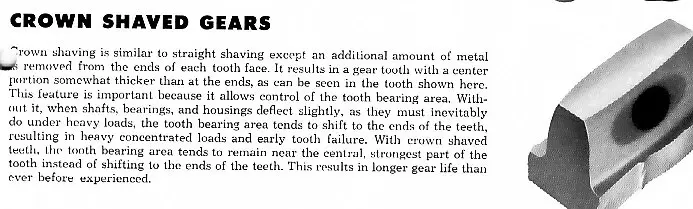

Non genuine gears in all applications are cheaper than Cat gears for several reasons but the main one is that they do not have the necessary crown shaving to allow misalignment that must take place between the panetary systems gears.

All Cat gears are crown shaved as nothing can be built in true alignment or hold it when under severe loads.

See pic below for explaination of crown shaving. To check for genuine gears I just used to lay my 6" rule along the gear tooth and if I could rock the rule on the tooth it was likely genuine--had customers try on re-work one time in regards to a final drive failure--for a start reports with serial numbers did not tally--client had 2 machines--but the ruler trick finished all arguments then and there--his answer was along the lines of --"oh well, it must have been the other machine then!!!!

The BB has become unstable with all this I have written so are going to post it before I loose it.

Ask more questions as needed and I will try and help out further.

Hope this helps,

Cheers,

Eddie B.