You have a wonderful day. Best wishes. Deas Plant.

Hi, OldRedTim.

If you have a 1/2 tank or more of fuel, I would have thought that gravity would do the job for you, at least to get it to the filter housing.

I think an electric fuel pump would work but I'd suggest trying for one of about the same flow rate as the original lift pump.

Just my 0.02.

is it difficult to remove the lift pump and check it's condition? you might find something else wrong or not 100%..

- and if its too rough of shape, replace with Cat Classic or aftermarket pump?

check your engine oil level and mark the stick and see if it is going in there

How are you stuck?

(In regards to) how is the tractor positioned...mostly level or on a bad angle?

If your back end is sunk bad maybe the fuel is running back to the tanK...

Hi Team,

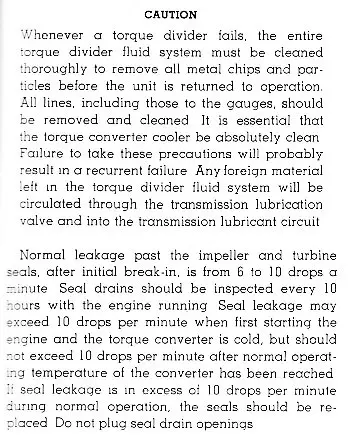

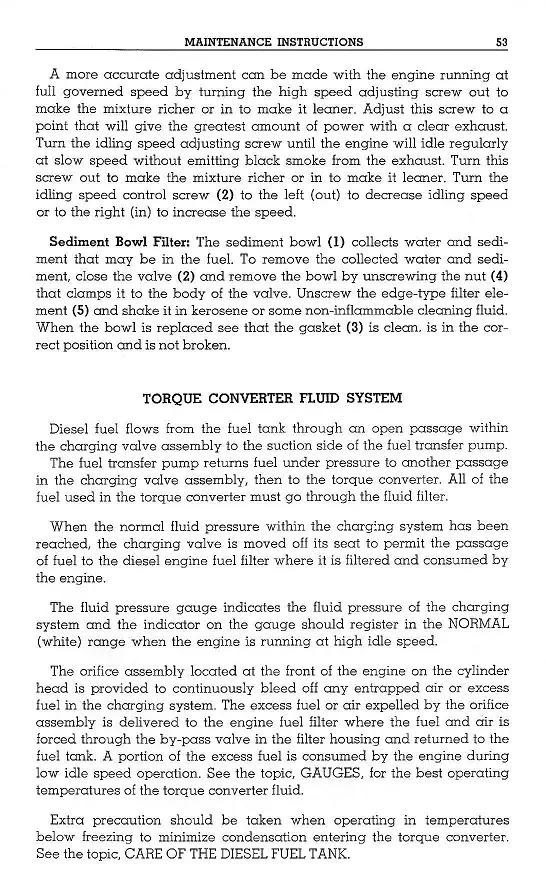

being a 3 Stage Fuel T/C in a direct drive tractor I expect that you may not yet have bled the T/C as per your grey Operation and Maintenance Instructions book.

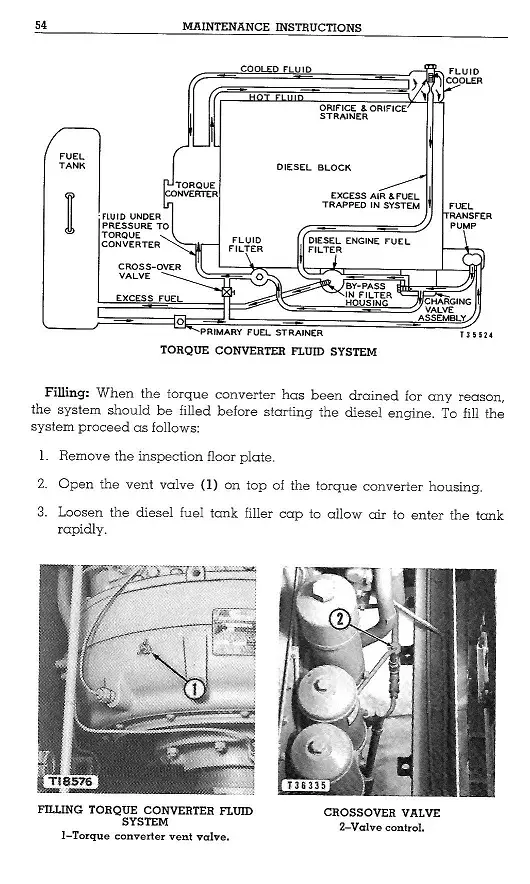

There are bleed taps on the main T/C case and a Crossover tap to be opened to make bleeding possible/easier.

It is likely that with air leaks the T/C is low on fuel and may take several gallons to refill and so bleed the air out to be full again--remember to keep the fuel topped off at all times to help keep the system charged--help inhibit air entry--this would be one of the reasons they built few of these before going to the single stage oil convertors.

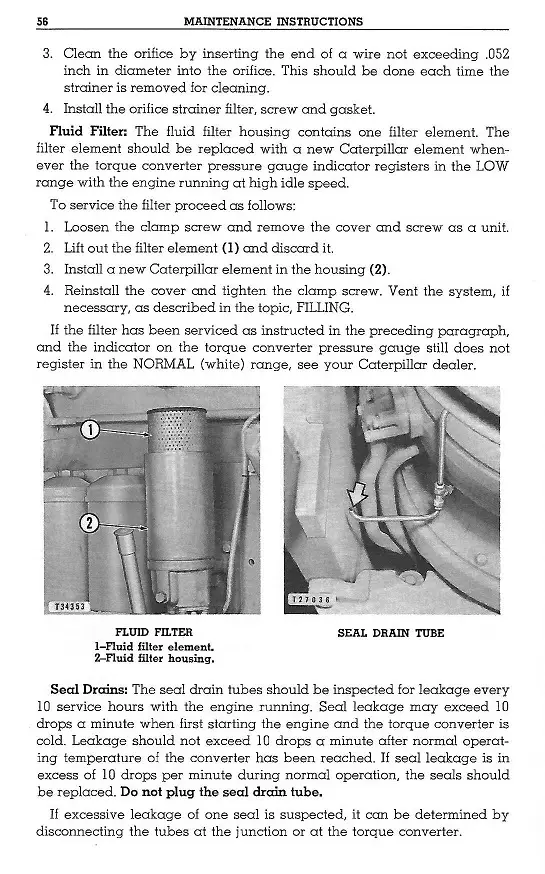

I also suspect that some of your fuel leakage is out of the T/C drain tubes due to leaking seals, and other possibly suspect bleed point taps etc.

These machines have to be kept/stored with Full fuel tanks and refilled every night after operating due to condensation effects as the fuel is heated thru the T/C in operation and then cooled in a jacket water cooled fuel cooler it is never really cool during operation.

OM has found a Twin Disc publication on these style of Twin Disc units that shows a T/C fuel seal drain tube leakage recovery system that would help alleviate your fuel to ground leakage problem--likely not cheap or simple to install but do-able to keep these jiggers going.

Now that I am not going away next week due to the virus pandemic I hope to get to search under the house for my Allis Chalmers Book on these jiggers and see if the recovery system is shown.

Stay tuned and ask questions and we will see if we can help more.

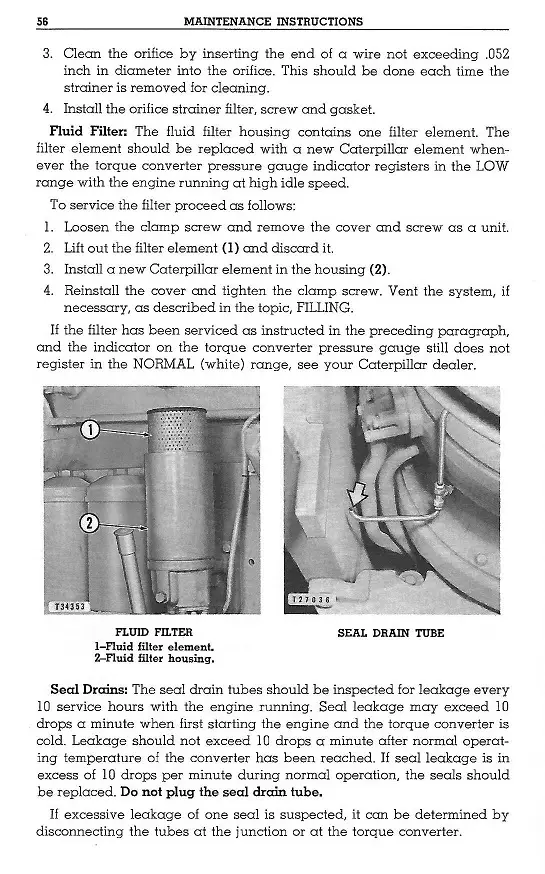

Hopefully the scans below help.

Cheers,

Eddie B.

If bleeding out the T/C does not do it.

Blow air backward from the separator with the tank cap off, this worked for me but I still had problems. I drained and flushed the tank as best I could with it still installed.

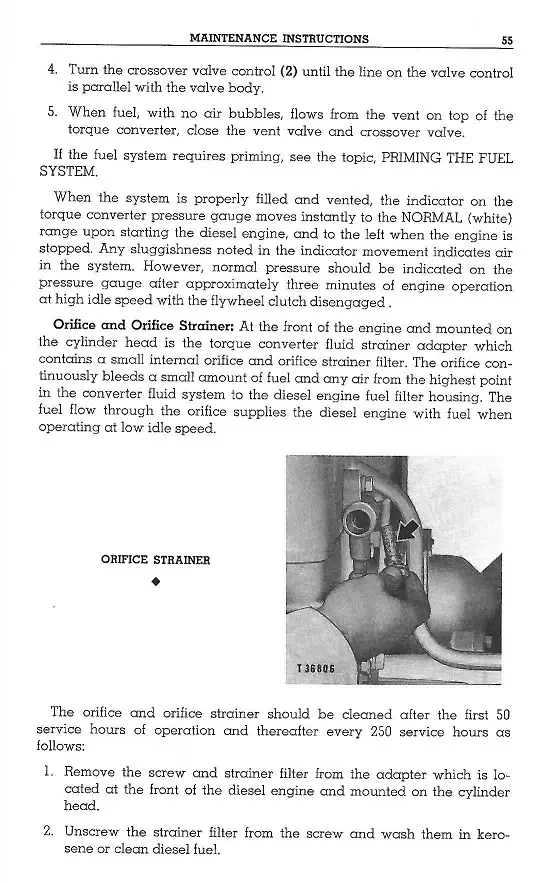

I'd pull the can off the bottom of the separator and clean it out, if you need parts they are available at Cat.

Then remove the top to the fuel filter housing, clean it out and put in a new fuel filter. You might need a new top gasket.

Then if you need to rebuild the fuel pump, the parts for this are available at Cat dealer also. The hardest part I found was removing the bypass line from the back of the pump. Don't bend it when you remove the pump and it'll line up better for the reinstall. It's a pretty straight forward rebuild. Clean and install new parts. There is a bolt that can flare the center shaft when it was installed. Just file it straight before you force the cover off.

Then you'll need to bleed the injectors before it'll start.