Reply to OzDozer:

Ahinkle - Wow, that's a serious project, in size and $$ terms! It sure looks very nice, and that will be one fine tractor when you're done. I trust you checked the rear housing for cracks? Those old D8's have nearly all lived a long hard life, and its rare to find one that has cracked somewhere in the rear housing. If you have a late tractor, it would have the heavier and reinforced housing. There's a big heap of service literature dealing with D8 rear housing strengthening and upgrades. Is it still on original 8.00" pitch undercarriage? - or has it been upgraded to 9.00"?

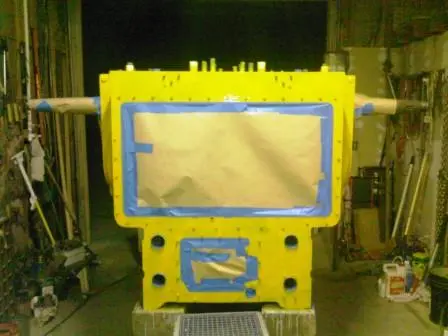

Richard: The sealer is to prevent future rust and to seal up the porosity of the casting, this makes the paint finish very smooth.

8C361: It's a 13a, sn 13A137

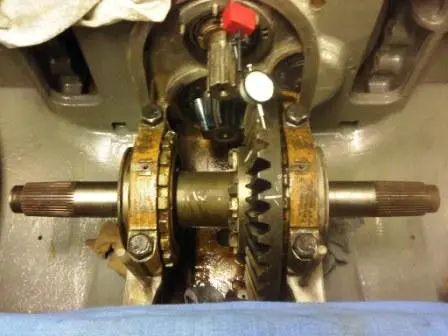

Old M: If I get enough overtime at work it will be done sooner. My biggest drawback has been budget. My plan is 2 more years. Yes this transmission is in A + shape. I had to buy 2 gears and replaced all the bearings. She should be trouble free.

OzDozer: I had 2 machines for this project. A 2U15564 and the 13A. One of the housings was broken where the dowel pin is on the right steering clutch fork boss. This housing is perfect and has all the late style reinforcements. It hasn't even been stamped with a serial number yet. I was unable to keep my serial numbers consistent with this project. I'm using the 2U block but the rest of the tractor is 13A I made sure all the engine upgrades are consistent with the 13A but I dont have a 13A block. My 13A had a power unit block in it so I'm making the best with what I have. The track pitch will be original, I got lucky with my 13A, It's rails have less than 50 hours on them and new bottom rollers at the same time. I will have to replace the roller seals and install new pads on the rails but the undercarriage will be like new. I have 2 good rear sprockets but I want to get 2 new ones to match the rest of the machine..