Hi Gator,

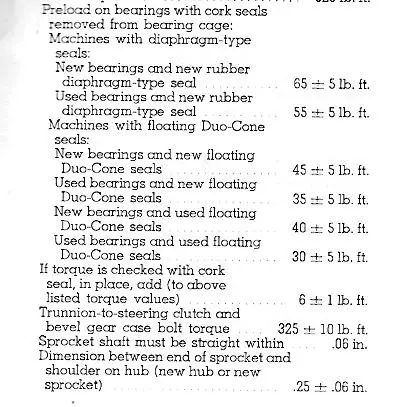

Yes you can adjust the outer bearings on a D8H, undo the track frame saddle and jack tractor so that the outer hub will rotate freely, remove cover and remove cork seal inside, weld a suitable nut to center outside of cover, replace cover with shims. Using torque wrench you can then test the torque to turn cover, with new bearings it is 60-70 ft lbs, bearings with more than a 100 hours should be less, maybe 50-60 ft lbs. This is due to the outer bearing also being the track trunnion bearing and the bearing rollers will tend to hammer indentations into the cone over time. Adjust torque with shim addition or removal, then remove cover and replace cork seal, replace cover and buckle everything up.

Wombat

The Cork seal was changed over years ago to a thick rubber seal, this is best to be removed and the Pre-load set without it, you will nearly always find the outer bearing failed in some way as it only moves in a limited spot, always fit a new rubber seal on completing the torque wrench setting, with the seal fitted you will really struggle to turn the hub when the cap is bolted up, so turn the hub to the correct index position so the key will match up with the frame, then tighten the key side of the clamp first, the outer cap fits with the big lugs on the cap in line with the split joint on the frame. tctractors

Thanks for all the replies it is much appreciated. I have oil leaking out of the cap. Pulled the final drives filler plug and have oil coming out. Seal issues between the finals and steering clutch compartment? What do you guys think? Changed the oil in the final drives and more come out than what I put back in.

Not uncommon, I'd just run it if the filters are clean and fix it when there is more reason to tear down. You can wedge a long pry bar against the sprocket to see if it has play, that will give you and idea of bearing health. The pinion seal is a separate issue. Cut open the filters and have a look

If you have oil leaking from around the outer cap that puts a stain down the Track Frame then you have Pre-load issues, the seal will also be failed behind the cap, even with the F/Drive oil being at the correct level it will still leak from this location as the oil is pumped into the outer Hub Via the oil rifle in the Dead Shaft, when cold it can amount to a few PSI inside. tctractors

When I pulled the final drive filter there was some fine flakes that were visible in the housing. Never cut open the filter as I figured I had my answer. Some times the preload is not checked often on these old girls so figured maybe everything was a little sloppy in the final drive department and that would explain the flakes? Possibility? You guys would know more.

I was going to check the preload and then the bar trick but was unsure of how to do that until you guys were able to enlighten me. Thanks again. I will try this in hopes that it eases my concern. Next question is how serious is the final drives being overfull? I’m assuming the trans/cross shaft compartment and steering clutch compartment are all one oil? Is that right? If that is the case then why would oil cross into the finals? Do the seals let go even though the bearings remain tight? I also run gear oil in the finals and a shell brand off highway trans fluid in the trans. It’s a 30wt. If they mix will that cause premature trans failure? I hope I got it all. Otherwise I’m going to become a pain in the butt.

D8H 46A series, transmission, bevel gear and steering clutch are a common oil compartment, I think the modern recommendation is TO4 30, Final drives I think is TO4 50, in the old days we used engine oil in all compartments including finals. The seals on the outer hub that carries the brake band let go and allow the oil transfer, can be old seals, pinion bearings on their way out, can also be the crown wheel bearing wear transmitting off center loads, particularly on the side furthest from the crown wheel.

Flakes could be bearing metal or gear metal, the bull gears are reversible on the same side, I have reversed some very rat eaten bull gears that did many more thousands of hours. The forward drive side wears much faster than the reverse due to lower loads in reverse. Higher oil level in the finals is not a problem in itself, what the cause is could be a problem that may lead to major issues and failure.

Please note D8H finals only lubricate in forward travel, so excessive long distance reversing should be avoided.

Wombat

Thanks for all the replies. This site is a wealth of knowledge! Two more questions please. My unit is a bare back. No winch, CCU, or ripper. If I pull the round plate on the back of the dozer. Could I put a bar in there and pry on the cross shaft or bevel gear and see if there is any play?

I just serviced the entire dozer. The suction screens were relatively clean and the magnets held a very small amount of fillings. Nothing to get in a skit over I don’t think. This is leading me to believe that the major problem is coming from the finals. Is this an accurate assumption?

Also when I adjust the final drive bearings do I need to split the track? Or can I get away with out. I ask only because I lack the gator link and would have to push the pins.