They leak lil to begin with but seals are a normal thing on 15a/35a's I doubt he had to actually buy a nother coverter unless bearings let go and took out some stuff with em

They are a diesel or fuel converter, use the same fuel the engine runs on, it circulates back to the fuel tank. they have a ceramic seal and it is normal for it to drip or leak when at so many drips per minute. Many people think because it is dripping it needs rebuilding, a wrong assumption. The master clutch is a single stage clutch and is more prone to failure if used incorrectly, you should decelerate before re engaging when changing direction etc. they were the first D8's to have a torque converter. It would be nice to own one for no other reason than they were the start of new things to come, viz; powershift transmissions etc and were Caterpillars answer to Allis Chalmers who had torque converters and were the new tool for scraper pushing. if it is in good order you are onto a good thing.

Wombat

Hello Wombat

I have a D8 15A that has a bad leak from the torque convertor into the clutch. Do you know if it can be fixed without removing the torque convertor or does both the clutch and the TC have to come out? The last time my brother drove it he said there was fuel leaking up through the floor. Not sure what is causing that but there is definitely fuel in the wet clutch.

Regards

Phil

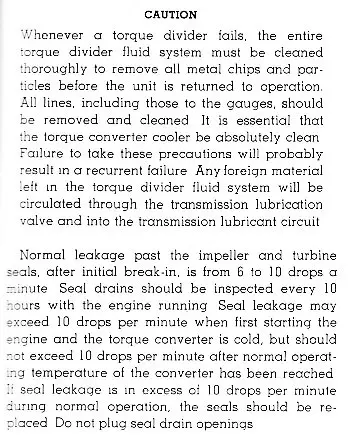

The two carbon faced seals are used in the torque converter to seal the converter fluid from the bearings. When the torque converter is operating, a very small amount of fluid continuously passes the seals and drips out the drain tubes. Be sure these drain tubes are not plugged or permitted to become plugged. The small amount of drainage is normal. Should these drains be plugged it is possible to cause the fluid to wash the lubricant from the bearings and cause a bearing failure. When seal leakage is in excess of 10 or 12 drops per minute, the seals are worn or damaged and require replacing.

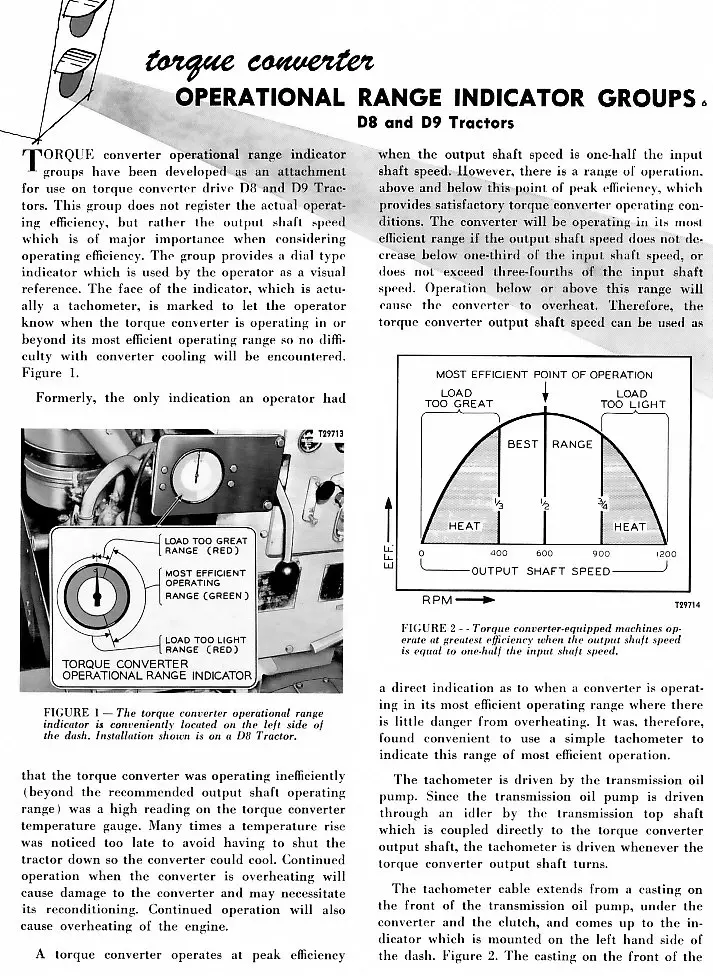

Also, then the tractor is idle with engine running, disengage the flywheel clutch to prevent torque converter heating. Remember, if the clutch is inadvertently left engaged with the engine running, engine horsepower is absorbed by the torque converter and converted to heat.

Kelly

Hi Team,

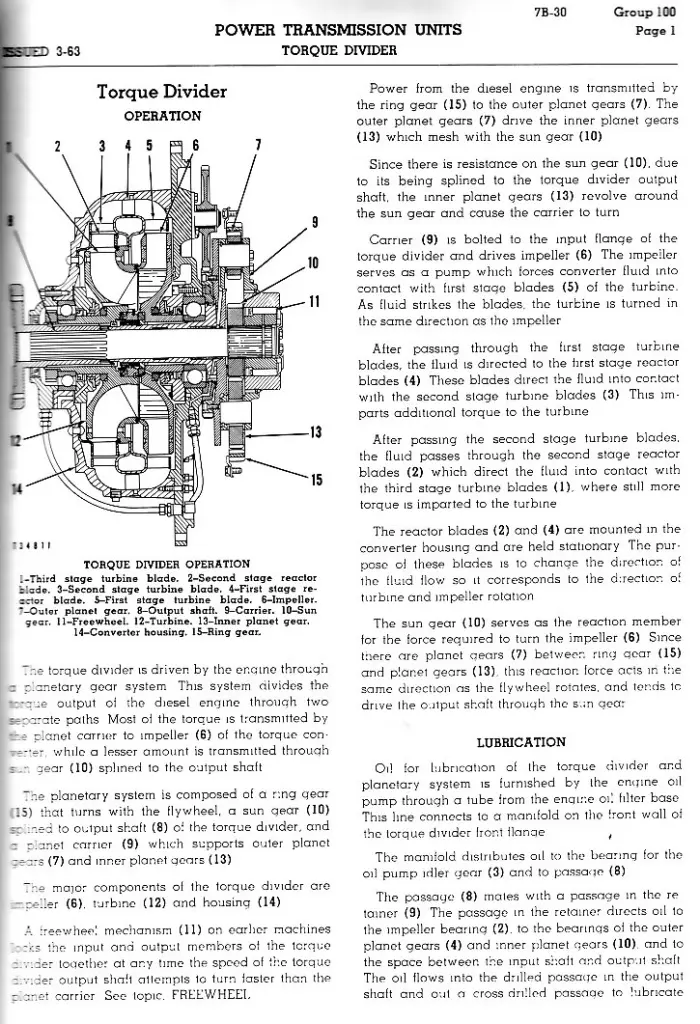

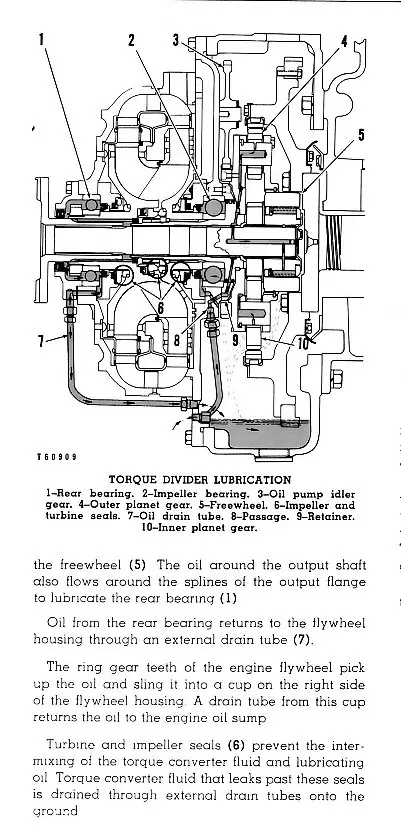

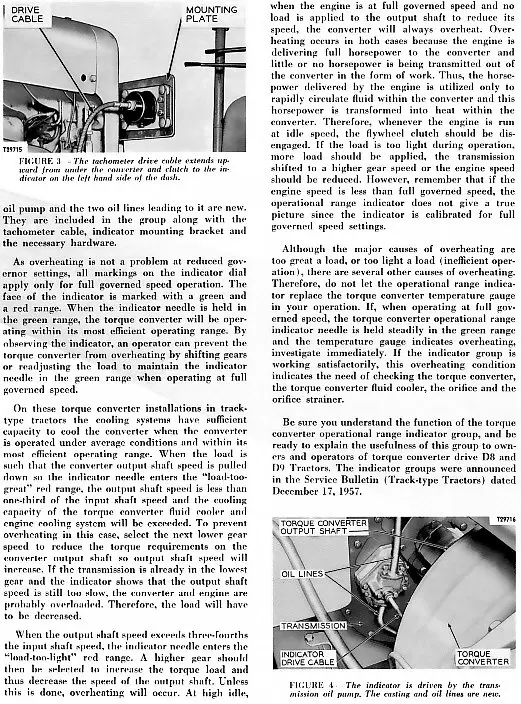

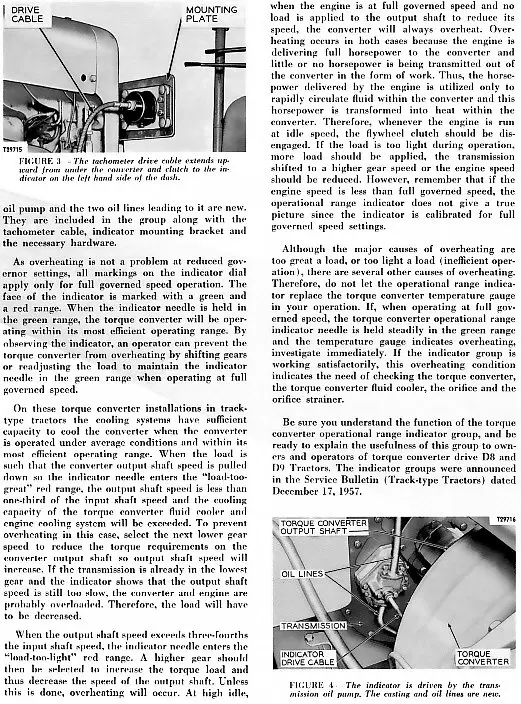

just to add to what Kelly said, the scans below are from a Cat School I did back in Oct 1965.

Be sure mud daubers or crud in the belly guards have not blocked the T/C seal drain lines. They should be checked daily (10 Hours of operation) as indicated in the lower paragraph of the 1st page of notes.

I have included the operation notes for these T/C's--note it is a Powershift Trans. version with the Torque Divider gear set, and not a Clutch type, but the operation of the actual T/C is the same. The clutch type has a longer input shaft from memory--too long since I did one--like 1966-ish.

Have also added an article on prevention of overheating that incorrect operating techniques can generate to add to what Kelly referred to above.

Hope this helps.

Cheers,

Eddie B.

Are new seals available? I'm past the 10 drips a minute point.

Last I recall they were extinct but then I haven't tried to find any.

I believe these are the part numbers:

Service group 6H1304, consists of 2 each

5H4975 washer and 5H4908 ring.

Hi Eddie,

could you please explain to the uninitiated why the torque convertor heats up if the clutch is left engaged while the gearbox is in neutral. I'm obviously missing a part of the picture here because I would have thought that with the gearbox in neutral, there is effectively no work being done (well, very little relatively speaking compared to a full-blade push). Is it the case that when the gearbox is in neutral, the output of the TC is stalled and this is what causes the TC to absorb energy?

Last I recall they were extinct but then I haven't tried to find any.

I believe these are the part numbers:

Service group 6H1304, consists of 2 each

5H4975 washer and 5H4908 ring.