Pioneernorth,

You have taken on an ambitious project. I will have a keen interest on your progress. I have a whole list of things to do to mine. Should be fun. Is yours a "wet deck"? I have a 1957 model SN 14A 7437.

Thanks for posting the pictures. Always good to have pictures.

JanM

Looks good.

I have a 15a I need to get back to before I forget where I put all the pieces.

About your roll over cage.... the cage itself looks strong enough but the connections to the rest of the tractor wiil fail in a rollover. So its really a "FOPS", not "ROPS".

I am aware that the home made cover is not a ROPS. I do have another 14a which came with a properly installed ROPS that was designed to fit a 1975 7G. It has proper heavy duty mounting brackets and was put together and certified by the BC government. I'm planning to put the "FOPS" on a 1947 2U that I have that has no canopy.

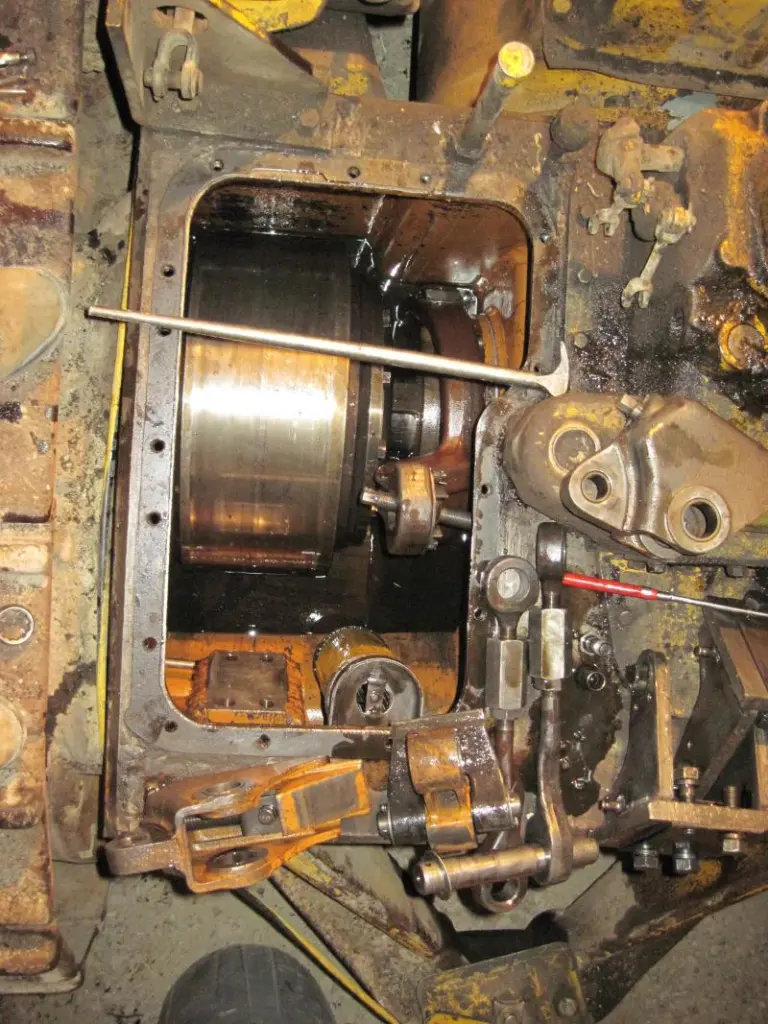

Got her in the shop. Took a little while because I had to finish insulating the ceiling. Got the wood stove cooking and toasty. Waiting for the led lights I ordered. Going to start stripping the steering clutches out of the carcass undercarriage tomorrow. Not sure about the oil leaking from the back of the back cylinder head. Might end up pulling heads and freshening up the valves. Haven't checked the thermostats yet but it does run cold and slobbery. Has a blue smoke puff every once in a while. Not warmed up though. Cheers. B

looking good. looks like you have a fine place to spend them long winter night's. keep up the good work

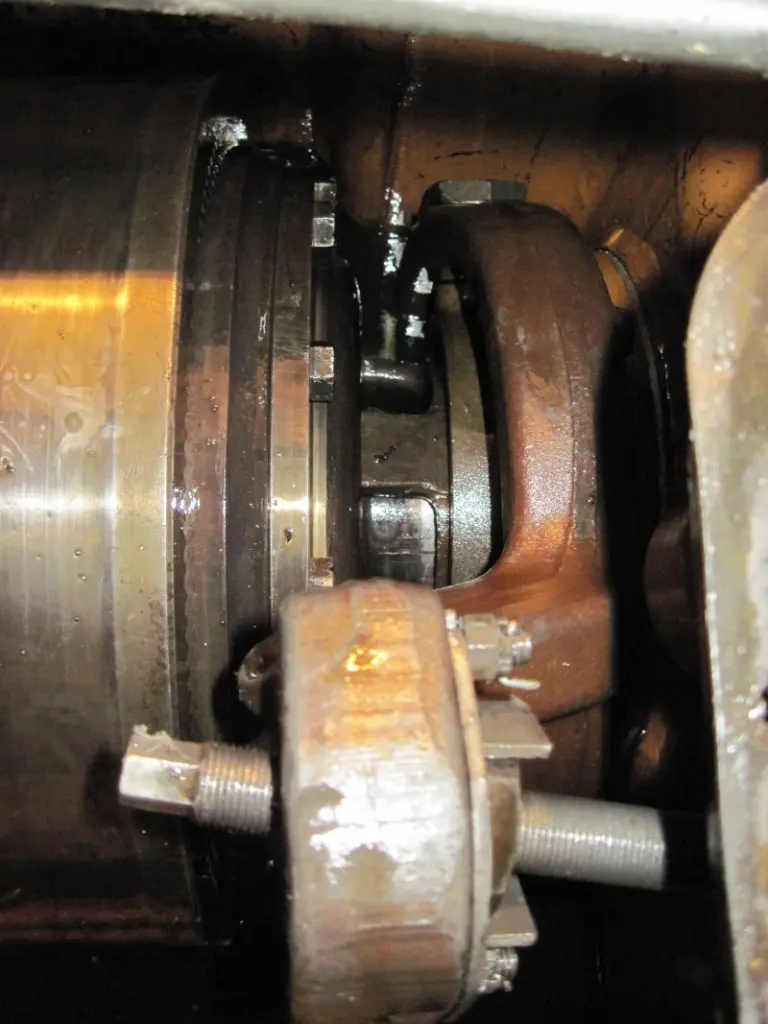

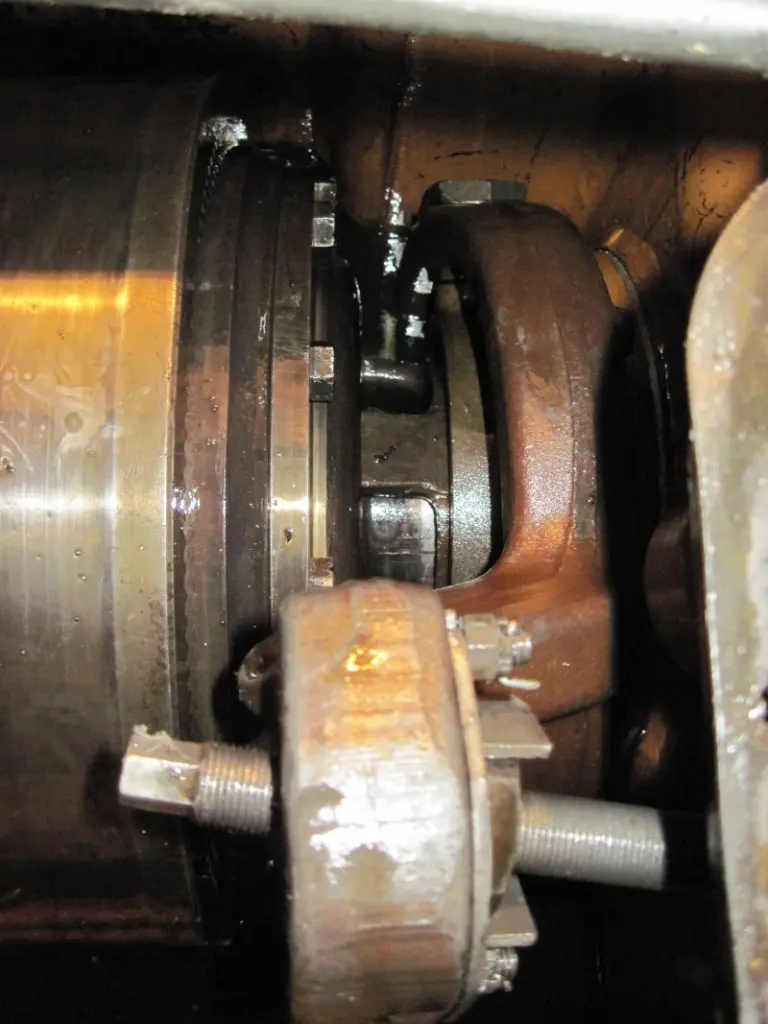

It looks like you have enough room in your shop to jack the tracks on the tractor to bring the bolts up to that 2" pipe plug access hole. It gets old and repetitive lining up those 12 bolts to get them out of the brake drum. Check the threads carefully on the brake drums you will use before installing them. I put three helicoils in my drum before the install and achieved full torque on the bolts.

The original I am fixing has 12 bolts around the brake drum. It is a wet deck machine serial number 6000ish. The parts donor is a 9000ish serial number and has the 24 bolt drums. The clutch/brake on the left side had a broken brake band, support springs totally missing and many bolts are not even in the drum on the pinion side. (about 7 I counted). The remaining bolts on the outside(pinion side) of the drum are just finger tight. The missing bolts and springs are not even in the bottom of the case. Someone doing really shoddy work! Also the bolts from the newer serial number machine have a bigger head and lock washer. Both sides of the tractor use the 12 bolts brake drums. The newer donor machine has 24 bolt drums on both sides. Does anyone know if the 12 bolt drum is actually intended for use in a wet deck machine? I thought I read the dry machines only used the 12 bolt drums. From measuring the position of the adjuster bolts it looks like the donor tractor steering clutches are just slightly more worn than the ones in the running machine. Probably going to just change the brakes and get all the bolts in place and tight. What do you guys thinks of lock tight. Really shouldn't need it with the lock washer bolts.

I can't answer your question about the 12 vs. 24 bolts. I wouldn't be in favor of using Loctite in the brake drum. You never know if you have to go back in and do another R & R. I bought new bolts and lock washers from Cat when I reinstalled my drum and steering clutch.

Wet deck machines 14A3861-up use 22 bolt drums. Choice of 7H2204 bolts 1-7/8" long or 9H6864 2-1/16" long plus lock washers.

Dry machines are 12 bolt drums.