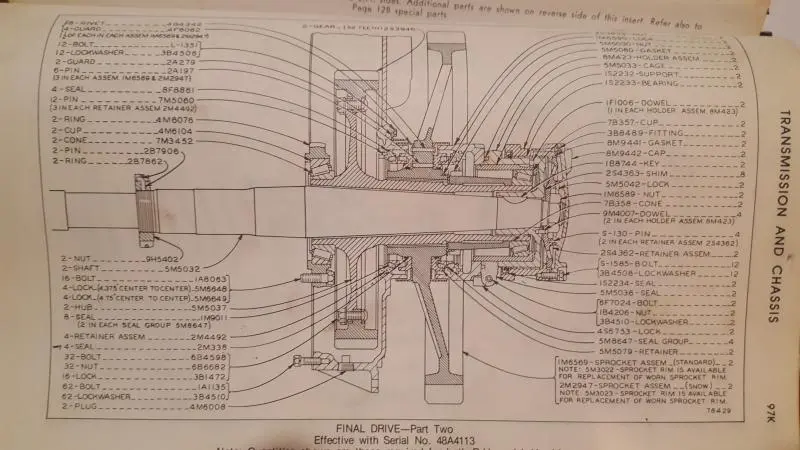

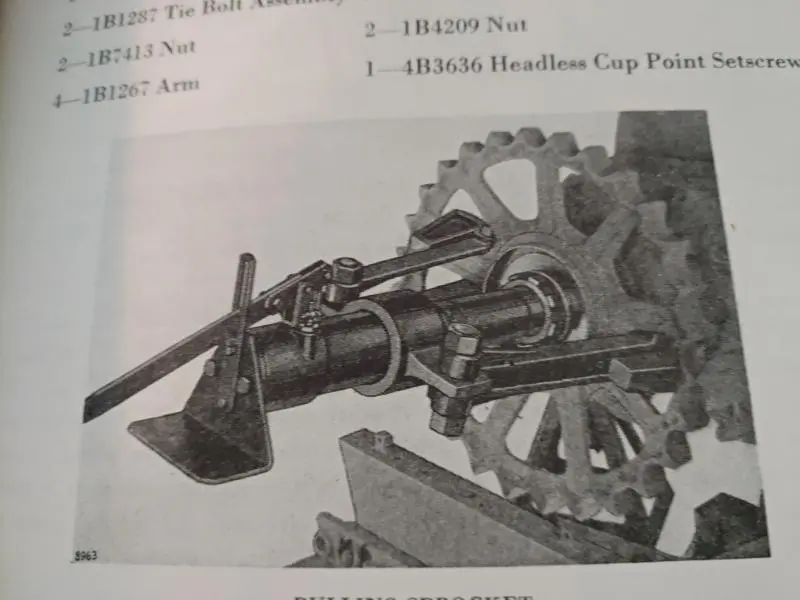

This is what they show in my book for my D6 5R for pulling off the sprocket.

[attachment=56236]P_20191204_191120[1].jpg[/attachment]

What I imagine it does is press on the shaft while pulling on the sprocket.

It looks like it has two arms that grab onto the inner part of the sprocket between the spokes while also having some wedges between the arms and the sprocket to keep the devices arms from moving outwards while it pulls on the sprocket. I think you want the pulling of the sprocket to take place as close to the center of the sprocket as possible.

To me it looks like a bottle jack you would use for a car with grabber arms attached to it.

I don't really know anything about removing the sprockets, so don't just take what I say as fact. Make sure you check with other people first.

In my mind, I sort of wonder if you could attach a heavy duty chain to the sprocket in a similar fashion as the puller and use some kind of winch attached to something heavy to pull it off. I don't know how much pressure you would need to pull it off, but you would want to make sure your tractor was sitting on something pretty solid in case the whole tractor were to shift if you tried pulling the sprocket off that way. However, again, don't try to remove your sprocket that way unless people with some actual experience say it would work or you would want to risk doing it that way.

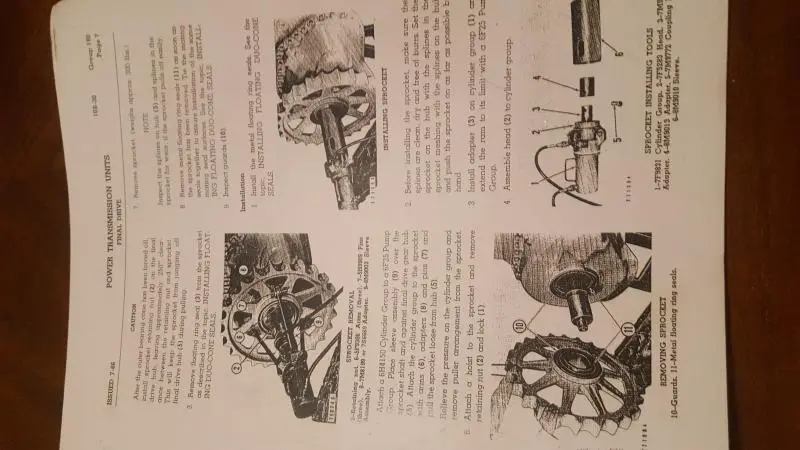

If you are wanting to do this type of maintenance and repair, I suggest you first buy a workshop/service manual for your serial number tractor. I suggest second, that it will be much cheaper to hire a press with or without a man than jerry building something. The proper tooling is made of high quality steel, there is machining/threads involved and if you damage the sprocket hub you will be in more trouble than the early settlers, if I remember from other old posts they are not available new.

I am not sure of D7E tonnages, a D8H requires 60/65 tonnes to press sprocket on and I have had up to 80 tonnes before they have let go when pulling them. You pull and push on the sprocket hub after you have first pulled and removed the outer hub. With those sorts of press tonnages things can go wrong in a flash and damage components at best and injure personnel at worst. The service manual will also give all the tolerances that you will need to make sure the sprocket does not press on too far etc.

Wombat

If you are wanting to do this type of maintenance and repair, I suggest you first buy a workshop/service manual for your serial number tractor. I suggest second, that it will be much cheaper to hire a press with or without a man than jerry building something. The proper tooling is made of high quality steel, there is machining/threads involved and if you damage the sprocket hub you will be in more trouble than the early settlers, if I remember from other old posts they are not available new.

I am not sure of D7E tonnages, a D8H requires 60/65 tonnes to press sprocket on and I have had up to 80 tonnes before they have let go when pulling them. You pull and push on the sprocket hub after you have first pulled and removed the outer hub. With those sorts of press tonnages things can go wrong in a flash and damage components at best and injure personnel at worst. The service manual will also give all the tolerances that you will need to make sure the sprocket does not press on too far etc.

Wombat

Do not pull or push sprocket off the dead shaft,you have a chance of either damaging the hub and bearings or busting the housing the dead shaft sits in

So it is the hollow hub shaft that the pressure is put to then bill?

So it is the hollow hub shaft that the pressure is put to then bill?

So it is the hollow hub shaft that the pressure is put to then bill?

Cdcompton, correct tooling is screwed on to end of hub and pressed off that. Ikhow of some blokes that made up there own but still have to have access to a 70t jack or ram at a minimum and that costs big bucks.

Yes, as Ray wrote, I had a couple of adapters made up for the D2 but I only had to get up to about 15t to pop them off. Even at that load, I hid behind the other side of the tractor to work the pump : )