Hi Team,

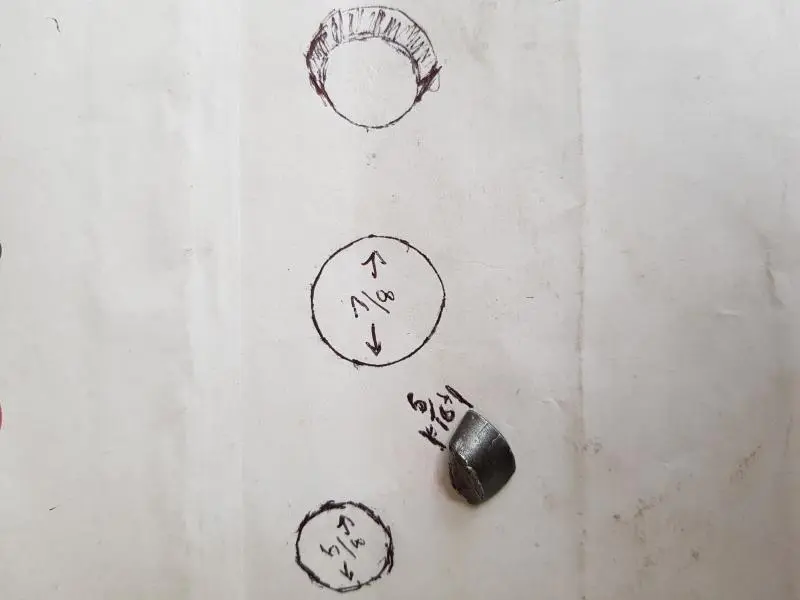

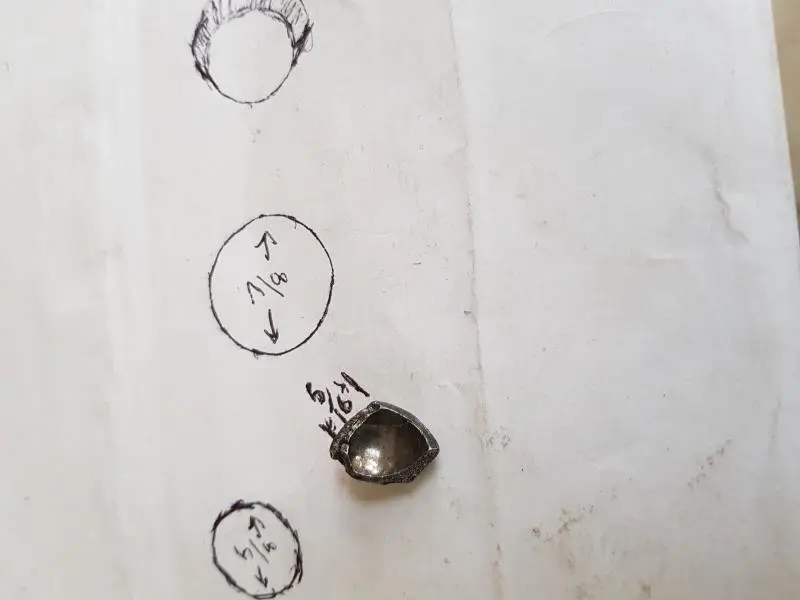

from memory the circlip looks to be from the oil pump/balancer shaft drive sleeve-- 2 are used to retain the sleeve in position between two drive shafts so the sleeve can be slid along the splines to enable fitment/removal of the oil pump and balancer units.

The metal pieces look to have been thru the gear teeth and could be part of a split/broken said drive sleeve or less likely a piece of a bolt lock tab gone thru the gearing.

I stand to be corrected,

Cheers,

Eddie B.

the partial cup one in the bottom of the picture looks like top of a lifter , and round clip might be out of the top of the lifter.

may be from some old problem and they did not clean the pan out.

just my 2 cents , good luck

I am hoping it is an old problem like you said caterpillar13 and bits not cleaned out of the pan.The partial piece of the cup could be part of a lifter being shiny on the inside from contact.The circlip could be for a lifter too.

I have replaced the thrust washer on the balancer too as the old one was partly broken and just about off,i have wondered what the cause of that was so edb when you mentioned the circlip from the balancer shaft drive sleeve,i was thinking it may have something to do with that.I have looked everywhere on the balancer and oil pump and all looks intact and not sure where the circlip would go.I will look at my manual to see if i can locate it.

The dozer was running fine about 6 months ago apart from an excessive oil leak from a welded up sump.I managed to locate a good one in the US replaced it then looking at my old oil pan,i found pieces of the balancer thrust washer in it.So not happy i had to take the sump off again but did,replaced the thrust washer and this is where i am now,finding pieces of metal in the suction bell filter.One piece damaged the mesh on the filter a little so just waiting on that part and gaskets.Its been a long 6 months without the dozer moving.The bad oil pan was a blessing in disguise though as the balancer thrust washer was about to fall to pieces and hanging on by a loose bolt so could have caused major damage.I will check my manual to see if i can find those parts you suggested Eddie and caterpillar13,

cheers John.

Like edb said the wire is 100% from the splined coupler that links the balancer shaft to the oil pump it goes on outside of coupler then the 90 degree bend goes in through a hole and protrudes into the oil pump shaft 1/4 of the way not all the way through... that being said mine is a low horse i only have 1 clip on pump side and it floats on splines on the balancer shaft side.. as far as other pieces to far gone for me to recognize sorry

Hi Team,

seems if the suction screen is worn/damaged from vibrating pieces with sharp edges then it has been there a while to cause the screen wear/damage.

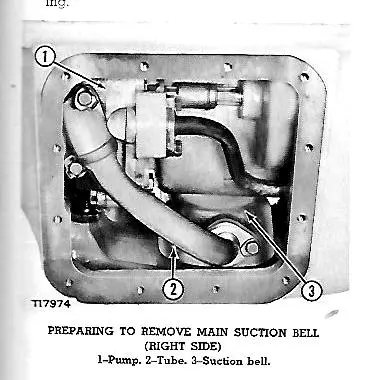

I do not have any books for a 48A BUT the 17A Service Manual (scan Below) shows the drive coupling and ring at about top centre of the opening as viewed thru the right hand sump side plate opening--if fitted to the D7E.

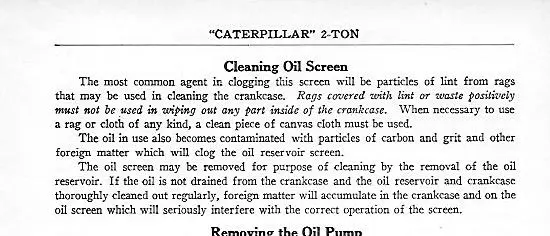

Another important fact is to not use rag--especially rag like track suit material etc. as outlined in the scan below from the 2 Ton Tractor Manual.

Once did a Failure Analysis on a 3512 engine that failed 6 hours a after a full rebuild by a client. Cut itself in half basically.

Finding was that the oil pump suction screen was clogged with lint from rags. The lint appeared to be track suit--wind cheater type lint.

Cheers,

Eddie B.

Yes that illustration is correct. that must be an early 17 a non-turbo the later Turbo 339s had a different larger oil pump. but the suction and scavenge lines in connection to the balancer shaft are all the same. But the coupler that that snap ring came off of is to the right of number one and above the front scavenge line in that illustration

Hi All,

i had a chance to look at the dozer today,i did find it was missing the circlip on the sleeve between the oil pump shaft and the balancer shaft.I do have a spare sleeve with circlip that i bought when i got the thrust washer and have noticed that

it has a thicker gauge circlip than the one i found in the bell suction filter.So you were right edb and cdcompton,you pointed me in the right direction on where to look for the part, thanks for that.I would be keen to find where the other bits and pieces come from but am hoping they are old parts from another repair previously.I just need to put a new circlip on the sleeve,then put the oil pan back on and hope i don't have any other problems,thanks everyone for your help,

cheers John.

I would lift the rocker covers and check in there, you could even adjust the tappet clearances while you were in there.

Hi Team,

it is true that the bits MAYBE an old failure, BUT ???

Those bits have been thru a gear train somewhere.

Look up into the timing case as far as you can see for any signs of bruised gear teeth etc. and turn the engine a few times to be sure you have checked most teeth that you can see-pull the generator and check the teeth up that high as well to be sure.

Have you checked the balancer shaft retainer plates for tightness. Is the oil supply line to them intact. The balancers are hard working due to their function of being off balance--maybe drop the balancer assembly and check it over as there are gears in there and the bits have been thru gears somewhere.

Cheers,

Eddie B.