Hi Dalton,

it is well known that the fan blade keepers in the hub at the base of each blade stem wear and so the blades flatten out as you have noted.

We saw this a lot on 769 dump trucks and anything else fitted with them after many hours of operating.

Overheating due to loss of cooling air flow thru the core is the end result.

Better to get a fixed blade fan as I do not think the reversible units are available new anymore--a used one is likely heading the same way.

As a temporary fix reverse the fan and continue operation.

I believe the intent of them was to reverse the fan to blow trash from the core or for easy reversal for winter summer operation etc.

If money was really tight you could likely dismantle the unit a weld up the worn components to re-use your existing unit.

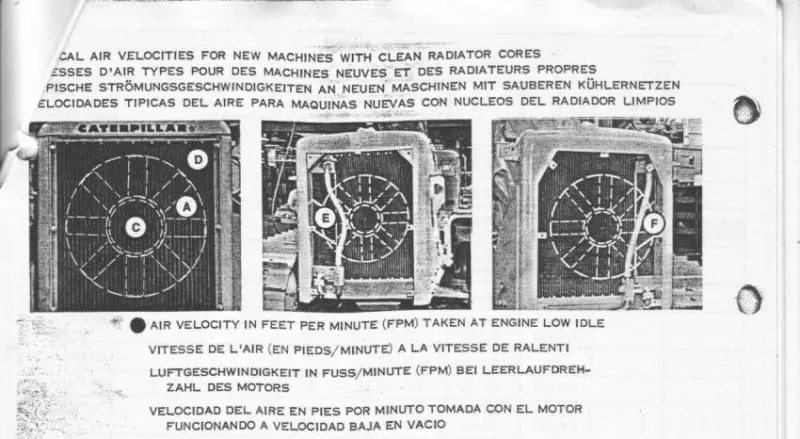

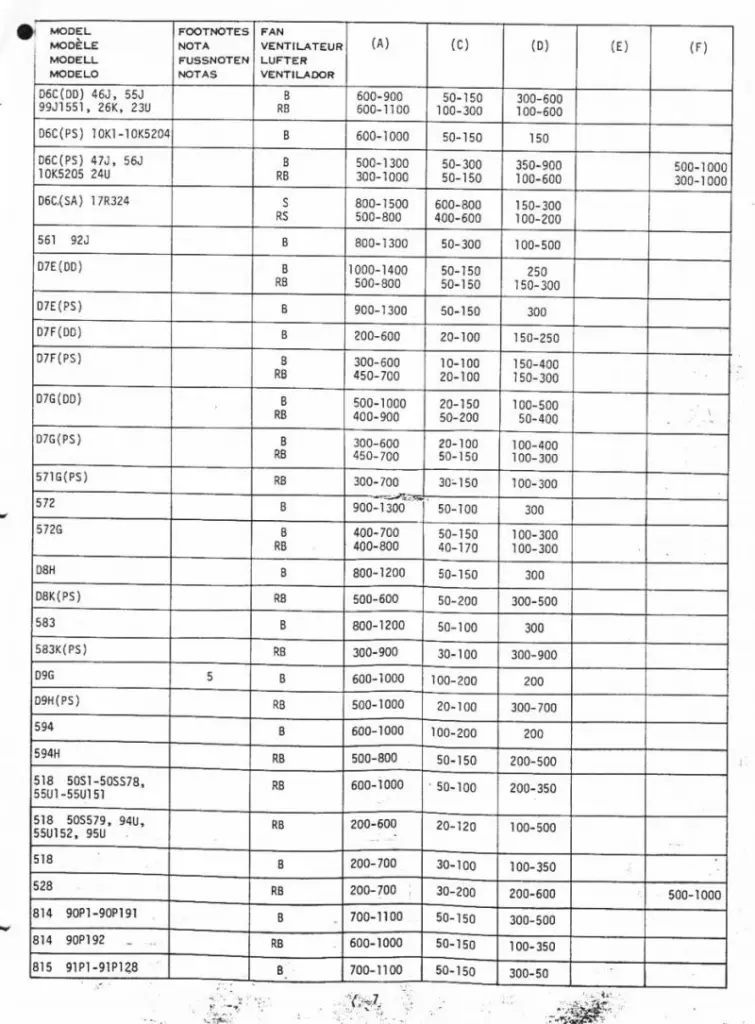

Air flow figures are given in the scan below as well as the areas of the core the expected air flows are to be taken.

Areas of the core clogged with trash inhibiting air flow will be evident by low air flows--a worn lowered pitch adjustable fan will be down on flow in all areas.

To check externally for trash in fins look in from the front of the core and use a work light behind the core to check for trash in the fins--dull or no light evident in clogged areas.

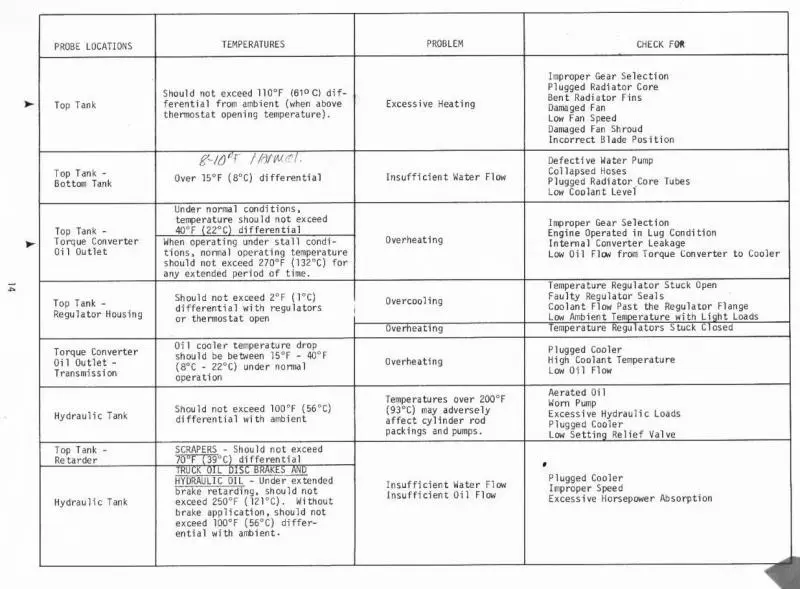

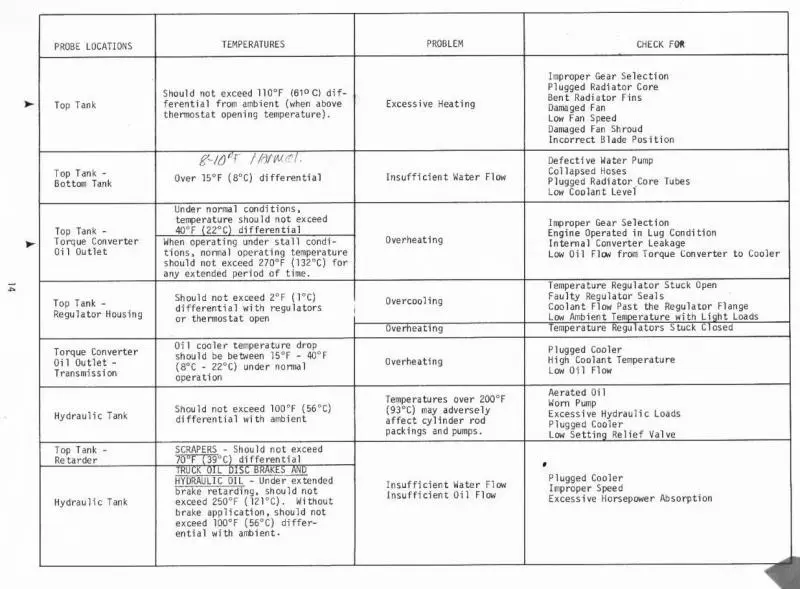

Also is a chart for expected coolant temperatures at given locations in the cooling system for diagnosing an overheating cooling system.

In older systems the engine oil cooler tubes at the water inlet side from the water pump can clog with crud from a rusty or dirty cooling system.

Hope this helps,

Cheers,

Eddie B.