There are two adjustments to be made. One is the over center adjustment done by pulling the pin/button and adjusting till there is definately a distinct snap with a reasonably hard pull.

The other adjustment is for the clutch and pinion control lever. It is adjusted by engaging the clutch and pinion and holding the lever as far forward as it will go and measuring the gap between the excentric block on the lever and the fork on the shaft below. Clearance should be 1/64-1/32". If it is not to spec, loosen the nut and block on the lever and adjust until it's right.

If you get no response to these adjustments then it's probably due to worn out parts in the clutch and dog mechanism.

Is your clutch lever going over center and latching in? My D8 clutch was not camming over and I had to hold it in to get the clutch to engage, I destroyed the blocks that push on the collar because they were pushing hard while the collar was turning. I needed to loosen the clutch up a long way until the lever would cam over. Now I get to pull the pony to replace parts that I destroyed.

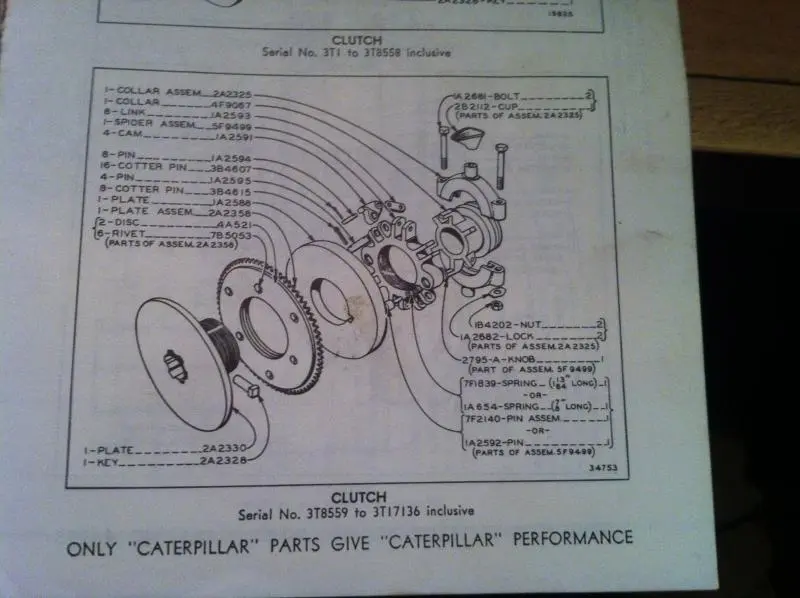

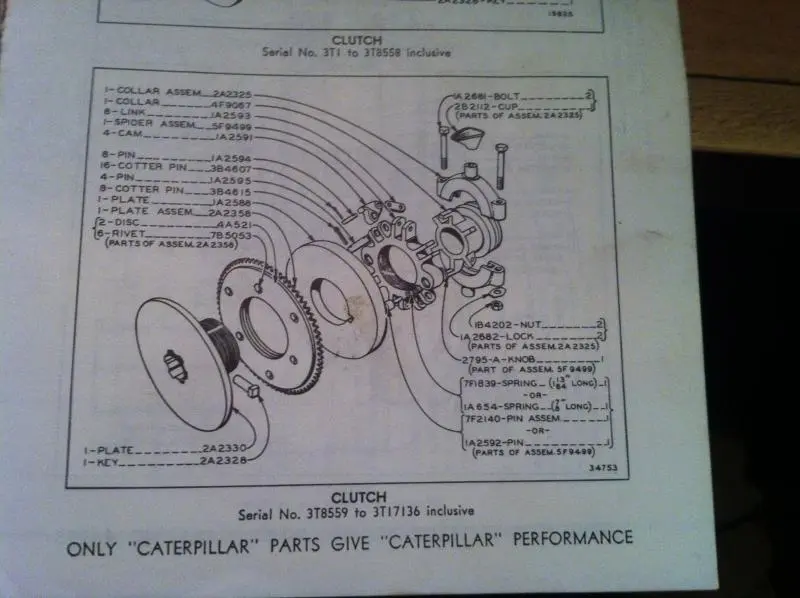

Your D7 is serie 3T and maybe your 1h1887 spider tread are worn or the collar 2a2325 to worn

Hello , I had this with the pony of my 3T D7 : there was a serious slip in the clutch of the pony . I adjusted the clutch so that the overcenter felt good .

After starting again there was again slip after some time . I noticed that the lining was seriouly "damaged". After removing the pony from the main motor I found all the lining material as porridge down in the housing . I don't understand how this was possible . Not any liquid could ever have entered the housing and as far as I know that lining is combustible proof . I mounted a new disc and it is running again . Who knows how the lining was solved ? The Netherlands , johan7

Thanks to everyone for their responses. So far, here's what I've found/learned. The lever at the end of the pinion was damaged. The set screw was broken. I removed the latch through the access hole and have a new one on order. I was also possibly experiencing a similar thing as johan7 described above where I would adjust the clutch, it would work well for one start, and then slip again. When I look through the access hatch, I don't see any damaged areas (but a lot of "crap" in the bottom of the housing, mostly greasy stuff). Once I repair the latch at the end of the pinion, I'll be in a better place to diagnose this problem. I suspect this may be the case because why would the clutch suddenly have disengaged? Has anyone heard of other reasons for the clutch not staying at the proper adjustment? I really hope that I don't need to remove the pony, but it may be the solution. Thanks again for all of your ideas. This message board is really useful. If anyone else would like some pics, just let me know and I'll upload them.

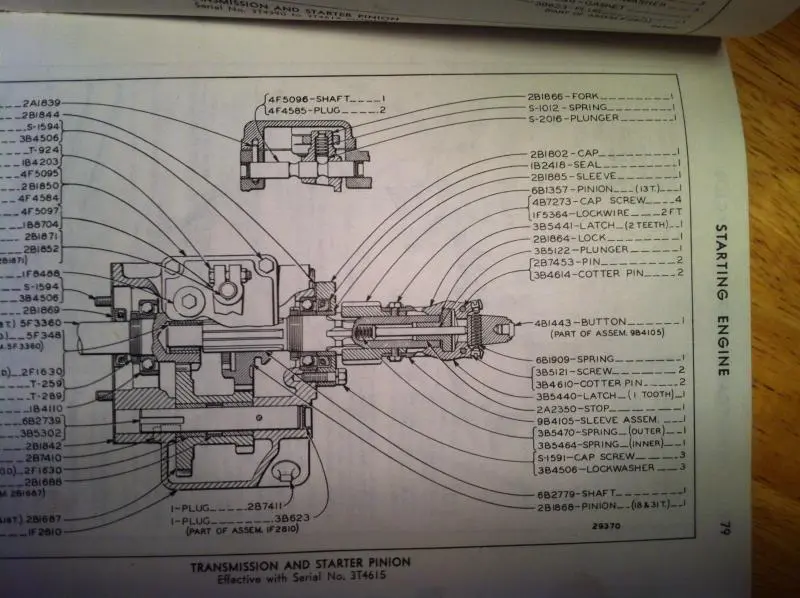

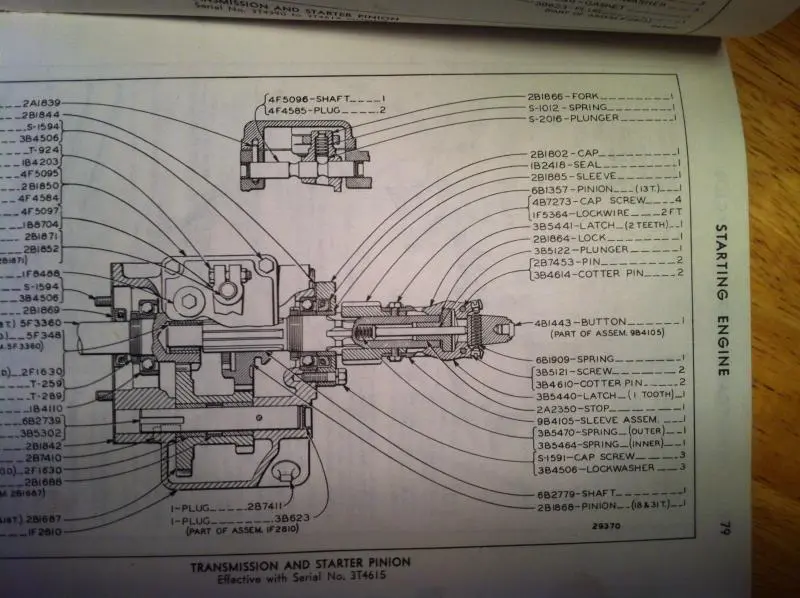

So, I ordered a new Latch (part 3B5441 image below) and the supporting pins, etc. and $240 later I installed them and the pinion is working correctly, I think. When I engage the lever, it stays engaged--which seems right to me. Learned some interesting things while replacing the latch, pin and cotter pins. I noticed that a previous repair of the pinion end (not shown in diagram but the area where the latch's pin engages the pinion) used a plasma cutter to remove the side of the case, come in and repair the pinion end and welding the case back together. I guess that's easier than taking the Pony off. I never would have considered it, but it's an option. All in all they did a nice job. For anyone reading this post looking to do that same: replacing through the access hole is possible but takes patience. I suggest getting one of those magnets on an 18" spring for when you drop parts down into the case. Take the main clutch cover off and also pull the drain plug in the bottom of the case and use the magnet to fish out the stuff you drop. I dropped the pin and two cotter pins and also an adjustment screw. Some the magnet got and others I must have pushed out of the hole because when I went to cover it again, my parts were sitting right there on the ground. It's a pain, but less so than pulling the Pony off.

So now, the only issue is that the clutch isn't staying engaged. I tried tightening the disk (pulling out the pin/button) and rotating clockwise. I rotated it all the way until it won't rotate any more. Thanks to the above comments from REB, I suspect that I've over tightened it and the first thing I'm going to try is loosening it quite a bit. I guess I don't know where it should be? I'm waiting for it to feel engaged when I move the lever over, but nothing so far feels like a lock. There was also a comment above from OLD MAGNET which explains the two adjustments. The first one I get, but the second one I'm less sure of. I took the lever and sleeve mechanism completely apart and I didn't see an opportunity for adjustment because it's locked in with two keys, thus there's no adjustment. I'm going to keep trying to understand the adjustment because I think this is the only remaining problem. The Pony is running great and when I really crank on the clutch, the Diesel picks up a bit but doesn't stay engaged. Thanks again for everyone's thoughts--don't know what I'd do without this resource.

[attachment=19162]IMG_1926.jpg[/attachment]

Forget about the second adjustment. That would apply to a 17A model that was originally claimed. No such feature on a 3T.

I think that the clutch plate is shot. Based on all of the diagnostics I've tried, I think that the part number IA2588 (Plate) is worn out and needs to be replaced. I'm a little confused because in the image I've attached, the plate has holes in it (which is maybe on the other side of the diagram). But as far as I can tell, it's the same part. I've never replaced this before, so I can't be sure if it's warn down, but it's the only thing that makes sense. I've tried adjusting the clutch plate to every possible position, and it just doesn't engage anymore.

Have you tried prying the collar to see if the clutch will go over center?

If the collar is well worn (and most are) you won't get enough travel to get over center and hold.