I cant see them in the parts book, but I believe there should be water ferrules with an o-ring in the counterbores of the head (they seem to have completely disintegrated) not sure if there should be water directors also (like there was on my D4-2T)? Anyways, my main concern is the pitting around the water passage holes in the block. I think maybe machine a counterbore, braze up and then deck the block may be a suitable repair? what are your thoughts on the head counterbores? How do you get the larger head studs out? (2 nut method wont shift them) I wanted to pull the liners out anyway to clean all the corrosion out of the block but now it looks like I will have to strip the whole thing!

It would of had water directors when new. As thick as the rubber washers are the corrosion may not be a problem. But that is a wild guess. In the back of my mind, I think I have heard of not using water directors. But again a guess on my part. Is it that Cat stopped using water directors on the late 5 3/4 bore engines???

Another thought could the voids in the block be filled a high heat epoxy? When young and broke I used regular J-B weld on the bottom of a sleeve in a JD engine to repair the o ring grove. I don't know how many hours we got out of that hunk of junk, but that was not problem that sent that engine to China. Hopefully some one with more knowledge will step forward.

Rd7s were not built for ferrules and seals. The later replacement heads had recess for the ferrule seal and the replacement head gaskets had larger holes to accommodate the seals. The seals are not o rings but a rubber seal that snaps over the ferrule. The block will not accommodate the ferrule. Stud (actually rod) removal is a difficult task. They go completely through block and main bearing caps. They are threaded into block above the main bearing caps and a nut at bottom end that holds main bearing cap in place. My experience with ones in RD6, RD7 and Diesel 50 is they do not want to come out. If they are stretched they will not come out. One was so bad had to cut where exposed in center of block pull top half out top and unscrew bottom out of bottom of block. I used a snap on collet stud remover. A 1 inch breaker bar would do nothing with 5 ft cheater bar. Usually had to use 1 inch impact. How stud remover survived that, I do not know. I plan on epoxy repair of corrosion around water holes. And return to using head gaskets and heads of original design. This is a Diesel 50 that was modified to 5-3/4 bore, which makes water passages way to close to liner. RD7 9g1-624 had small water passage heads no counterbore and used head gaskets with small holes, so will work for my modified D50. What is serial number of your Tractor?

A few pictures of the thru bolts. I forgot there is a lock that prevents it from turning where screwed into block. Fine threaded end is head, coarse thread is bearing end.

Depending on diameter of water passage holes in block ferrules may or not fit. Ferrule od is approximately 5/8 inch. Hole diameter in my non ferrule blocks is approximately 1/2 inch. Appears the first application of ferrules and water directors was the D7 7M first produced April 1940. The 9G RD7/D7 was produced January 1935 to January 1940.

This is a very good thread. I am learning quite a bit here. Thanks for the original post, and thanks to those able to share their wisdom as well. Amazing stuff. JM

Well I will not take it apart to check, but am sure the RD 6 here has water directors. It was before 85 the last 9G head I had off. thank you for correcting me.

Ray, it is quite likely your RD6 has a replacement head which would be designed for ferrules and directors. There are very few RDs with original heads. I think, but not certain that water passages in block could be enlarged to accept the ferrule. Only possible issue I see is alignment of enlarged holes with the holes in head.

Rd7s were not built for ferrules and seals. The later replacement heads had recess for the ferrule seal and the replacement head gaskets had larger holes to accommodate the seals. The seals are not o rings but a rubber seal that snaps over the ferrule. The block will not accommodate the ferrule. Stud (actually rod) removal is a difficult task. They go completely through block and main bearing caps. They are threaded into block above the main bearing caps and a nut at bottom end that holds main bearing cap in place. My experience with ones in RD6, RD7 and Diesel 50 is they do not want to come out. If they are stretched they will not come out. One was so bad had to cut where exposed in center of block pull top half out top and unscrew bottom out of bottom of block. I used a snap on collet stud remover. A 1 inch breaker bar would do nothing with 5 ft cheater bar. Usually had to use 1 inch impact. How stud remover survived that, I do not know. I plan on epoxy repair of corrosion around water holes. And return to using head gaskets and heads of original design. This is a Diesel 50 that was modified to 5-3/4 bore, which makes water passages way to close to liner. RD7 9g1-624 had small water passage heads no counterbore and used head gaskets with small holes, so will work for my modified D50. What is serial number of your Tractor?

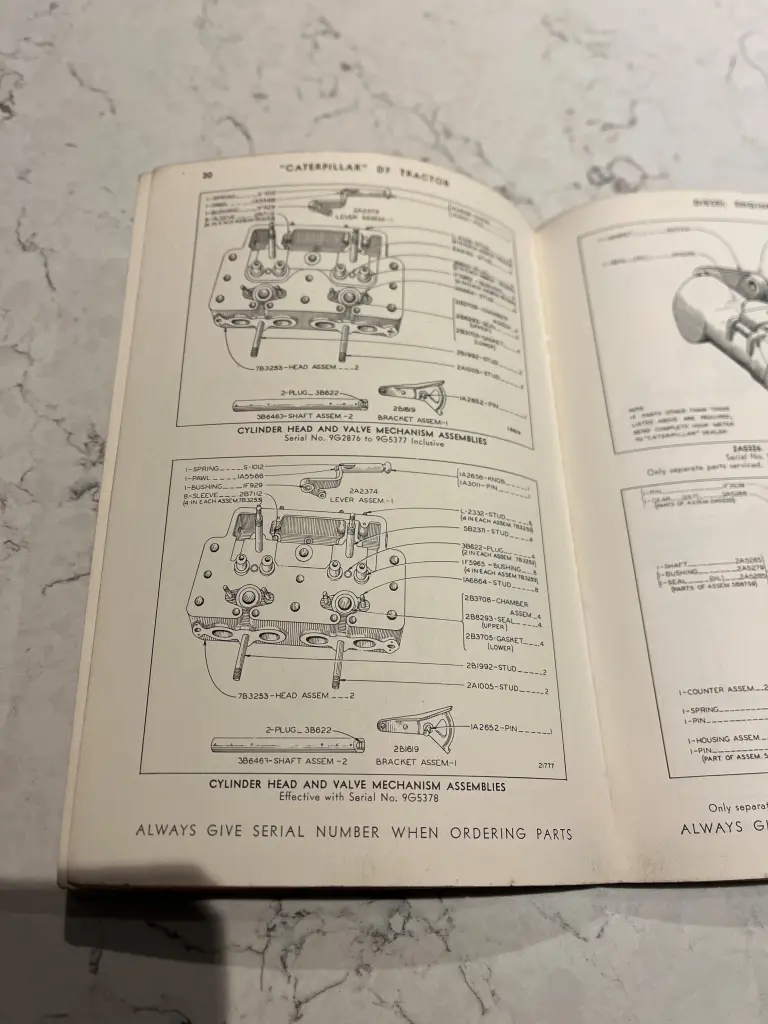

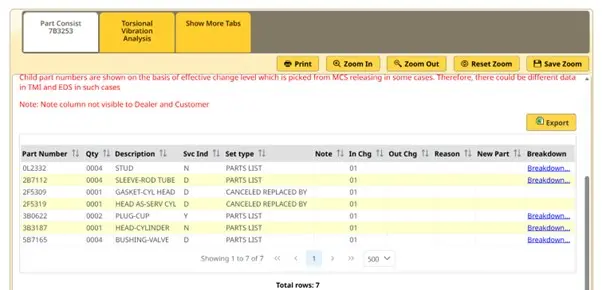

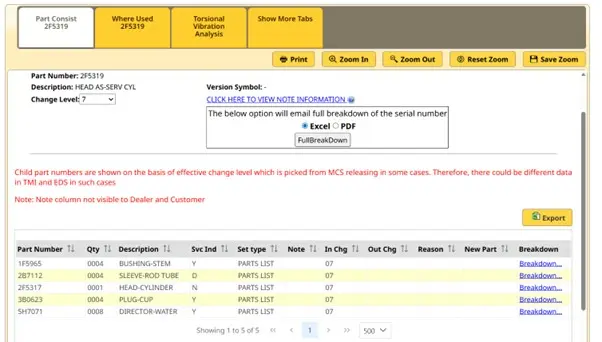

Brian, thanks very much for your reply. With regards to the water passages, what you say makes sense. The water holes in the top of my block are around 1/2" and the holes in the head gasket & the counterbore in the head are slightly smaller than 1 1/4". The parts book shows 7B3253 for the head assembly, with head gasket 3B1242. TMI shows replacement HEAD AS 2F5319 and GASKET CYL HEAD 2F5309. My engine has heads 2F5317 (part of 2F5319 assembly) , so has the replacement heads & gaskets - just like you said. Was the intention that the head gasket would seal the water passages, then they had issues and changed to the ferrule/seal setup, but didn't consider this for D8800 replacement heads, or maybe there was a service bulletin to do something do you think? My tractor serial# is 9G7801

Apologies Brian, just noticed you replied to Ray about enlarging the holes in the block. I think there must have been a factory instruction for this at one time to allow the ferrules to be used in the replacement heads. Like you say picking up the hole centres would be tricky, I work for Catepillar and was hoping I could find a drawing for the block but no such luck, I did find a drawing for the head though so could maybe find the centres of the water holes from the bolt holes