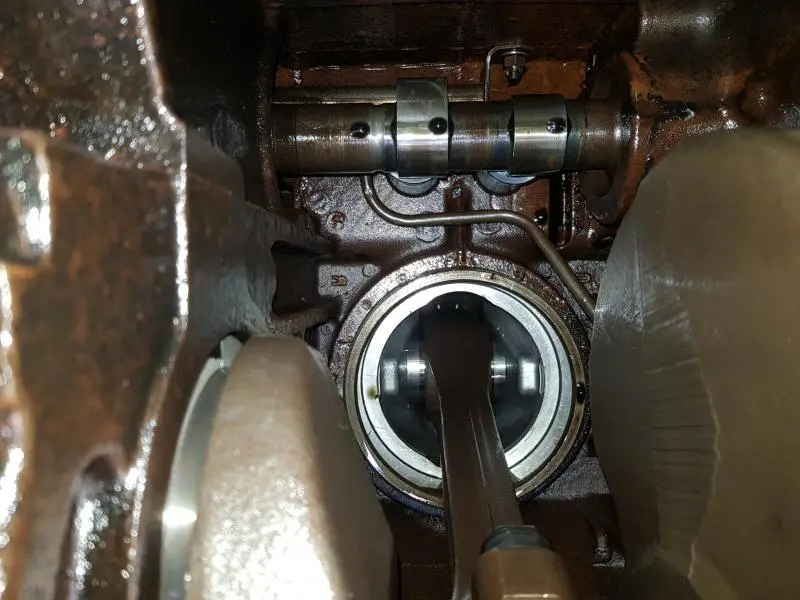

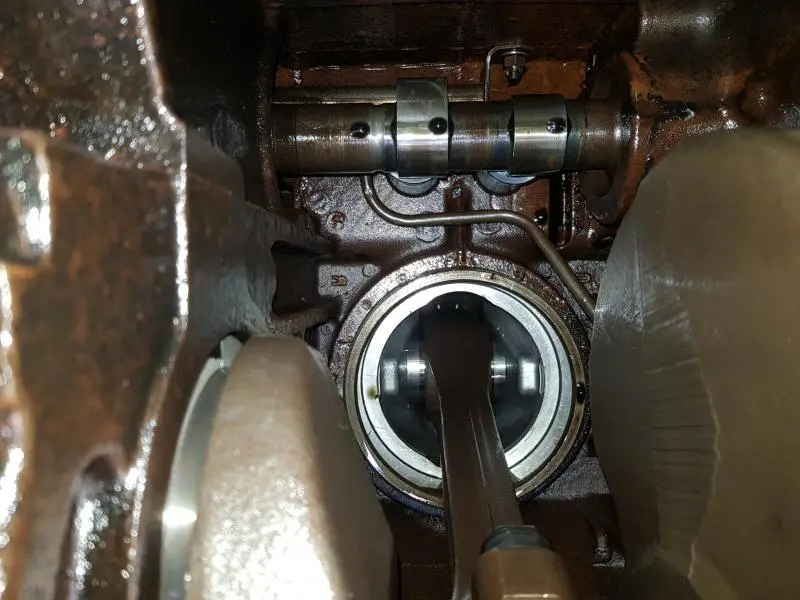

Hi All,so i've been waiting weeks for my replacement oil pan to arrive from the US as my original pan had seen better days.Anyhow my new pan did arrive,i managed to get the old front oil pan off in house which was not easy as the rear bolts are near impossible to get to.All was looking good,i took a few quick pics before replacement with the new pan and in my hast to fit the new pan without looking further have come across a few major problems.I fitted the new pan perfect but the next day as iwent to clean the left over oil out of the old pan,i found a few unwanted surprises,parts of the balancer thrust washer were found including one of the bolt heads which hold the washer on.I checked my pics and can see where it is broken off just holding by one bolt.I'm not sure how it has happened maybe a bolt has come loose causing the breakage.I will have to take the sump off again to have a better look.

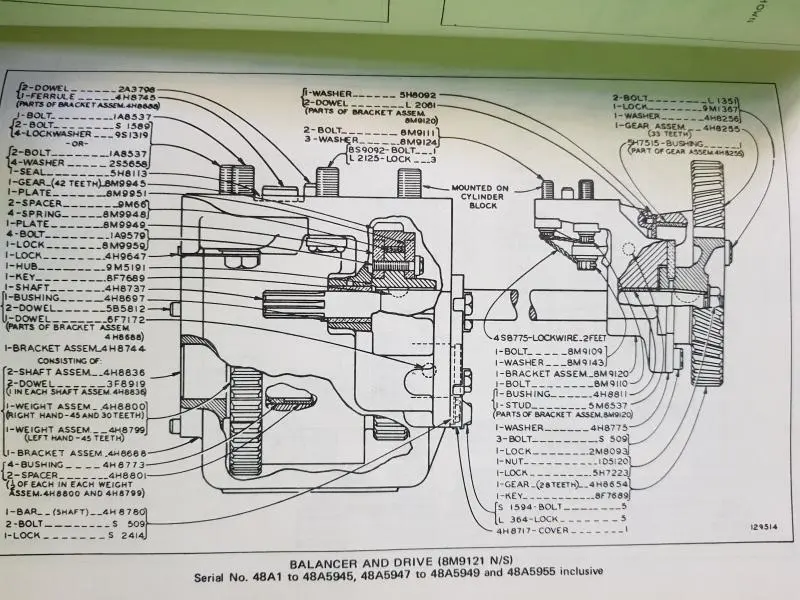

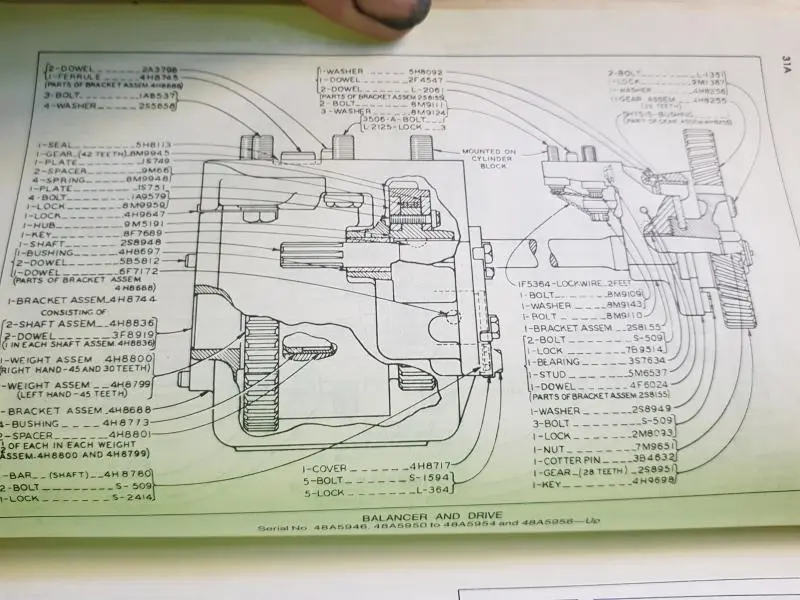

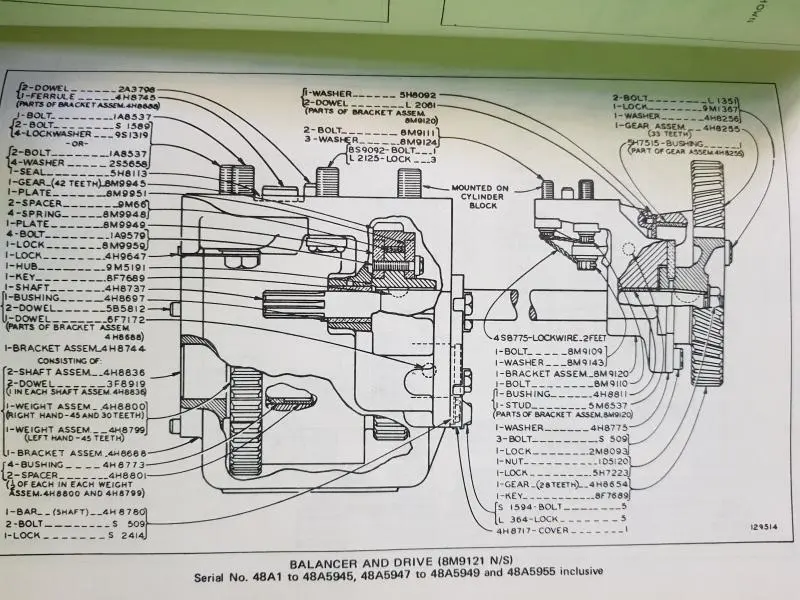

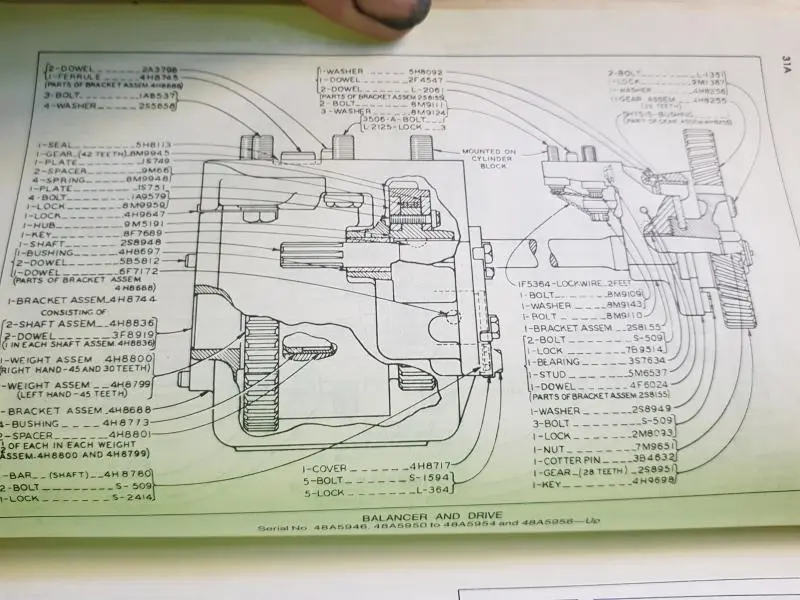

I have been trying to get a new washer part number 4H8775 for my low horsepower(serial 3196) but they are no longer made by Cat.I have had a look online and the washer is not available anywhere.Looking at my parts book,the number was changed from serial 48A5946 to part number 2S8949.The bolts lock plate part number 2M8093 is the same for serials as is the three bolts part S509.I have managed to get the bolts OS-509 cap screws and also the lock plate.

My question is will the later serial thrust washer fit mine as the lock plate and bolts are the same.I have ordered part 2S8949 washer hoping it is,if not it might look good on the mantelpiece.

Also,can the new washer be installed without taking the gear off as it looks lke a major job,until i take the sump off again i won't know,if it can be done i won't be able to torque the bolts as the gear is in the way.Any help would be appreciated and if the new washer is not the same,i will be looking for a good used washer or a new one preferably.While looking at my pics closer,i did find a gouge at the underside of one of the pistons and sleeve maybe from the broken bolt floating around,the guy at Cat should be all good but check for scoring in the liner.I have put a few pics up,

cheers John.