D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

i think you are right. rebuild the steering clutches.

Check the final drive oil also, does it look gray/silver, milky, dirty? When was the oil last changed?

I have not changed the final drive oil since I had the machine about 5 years. I keep it topped up but the oil looks OK in the filler cap. The gearbox oil had moisture in it as I was getting a white milky sludge build up on the inside of the filler tube and under the filler cap. I have changed the gearbox oil since. Are you saying something might be seizing up in the final drive as it is all gear to gear from the steering clutch through looking at the service book. This is why I am leaning towards something in the clutch system.

If the oil looks ok then it should be fine, if it was gears and bearings failing then you would be hearing and feeling some strange noises and the oil would be showing signs. Most likely then the steering clutch disc are worn and the brake band lining may be thin or gone. I assume you have checked the adjustments and booster oil level first? There are some inspection covers on the back case on each side also to look into the clutch case.

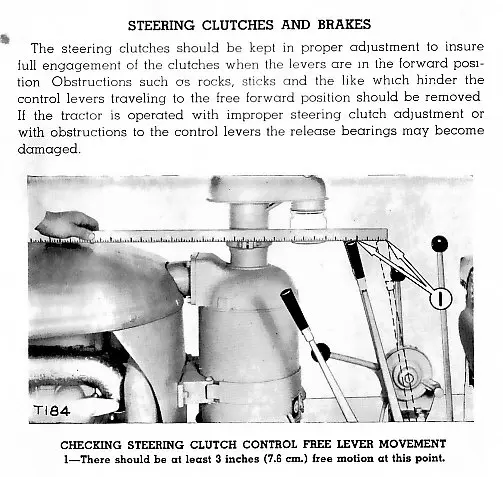

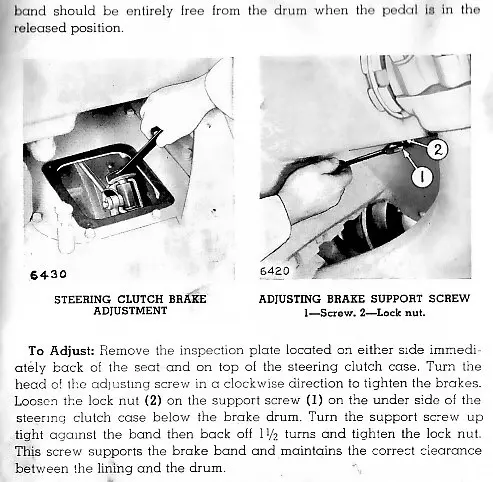

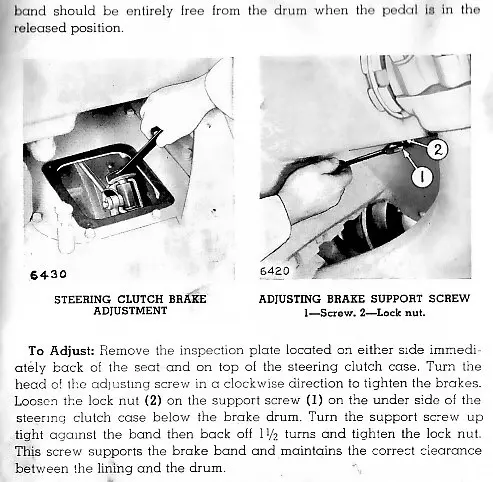

Have a go at adjusting the steering clutches and brakes before tearing into it.

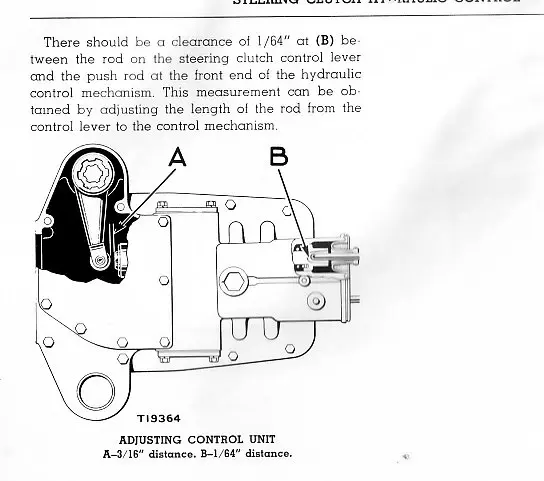

Should have 3" of lever travel when adjusted right.

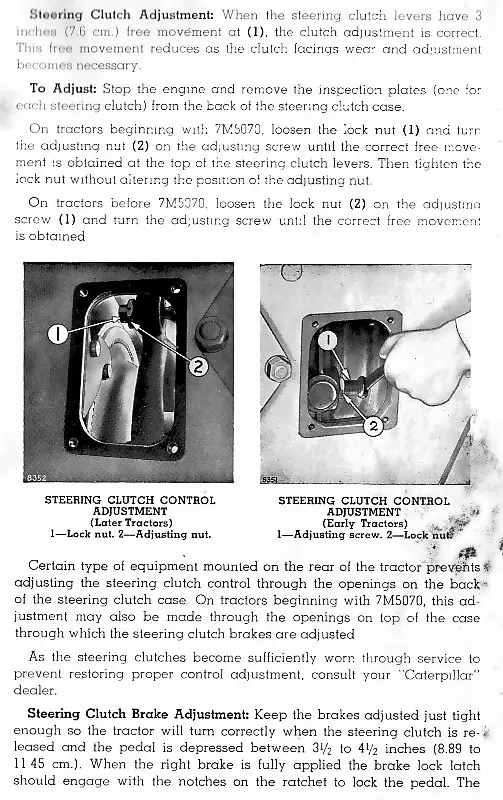

On the brakes tighten up the brake band adjusting screw, then run the support screw under the tractor up tight and then back off 1-1/2 turns.

Hi,

as OM said, you should first off carry out the steer clutch and brake adjustment before ripping your machine apart--first step of troubleshooting, check and return the machine to factory adjusted specifications, ie, carry out adjustments.

Also check that the rubber lever bump stops for the operators steer cl. levers are in place and there are no sticks/rocks etc. between them and the operators lever so they cannot fully return.

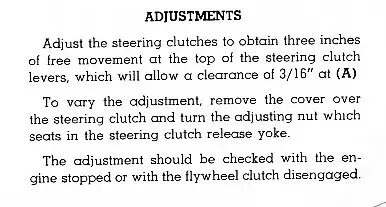

Scans, last two, below explain about clearance between steer lever rods and booster piston.

As the clutch pack wears the adjusted lever clearance diminishes until it is all used up and then the clutch spring apply tension is lessened and the clutch slips.

Scans below from the Operation and Maintenance Instructions Book, Form No 10481, should help you to adjust the pack linkage in the steer clutch compartment.

One of these books is vital if you are working this machine--check Ebay as they show up--reprints should be available too but sometimes the pictures are not so good.

Cheers,

Eddie B.

You’re thinking correctly......just follow through the logic......

with sufficient wear to the disks and linings, the clutch pack pressure plate and drum move closer together loosening the spring pressure slightly, but the springs can still compress things tightly enough that it transmits power.

However, the free travel in the clutch linkage disappears as the pack/stack thickness diminishes. Eventually the free travel is all gone and the control linkage begins to hold pressure on the clutch release bearing all the time and diminish the spring tension applied to the clutch disk stack. This is just the same as “riding” a foot clutch in a car or truck.....bad for the throw-out/release bearing and makes clutch easier to slip.

So, it begins to slip more easily under load ..... usually first noticed when you pull the OPPOSITE side steering clutch lever and all the power/all the load is applied to just the one side, so the tractor just stops instead of turning away from the weak side steering clutch. Release the clutch on the good/better side and tractor moves off again with mostly normal power. This is because each clutch is normally able to take all the power available from the engine, so when they’re both engaged, even somewhat weak clutches will transmit enough power to drive in a straight line.