Reply to Ed RD7:

Hello Clint,

I might be able to give you a few ideas. We have one on a 17a that we recently overhauled. First off, do you have the operators manual, I found one on ebay.

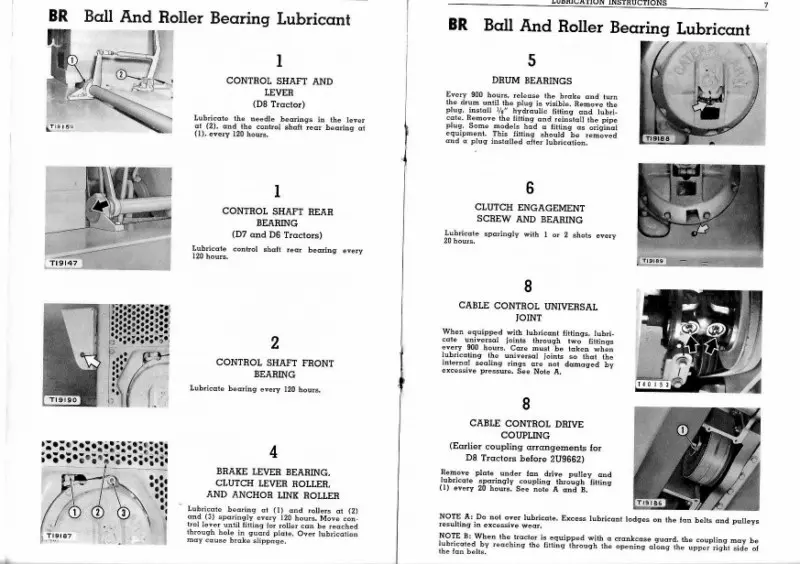

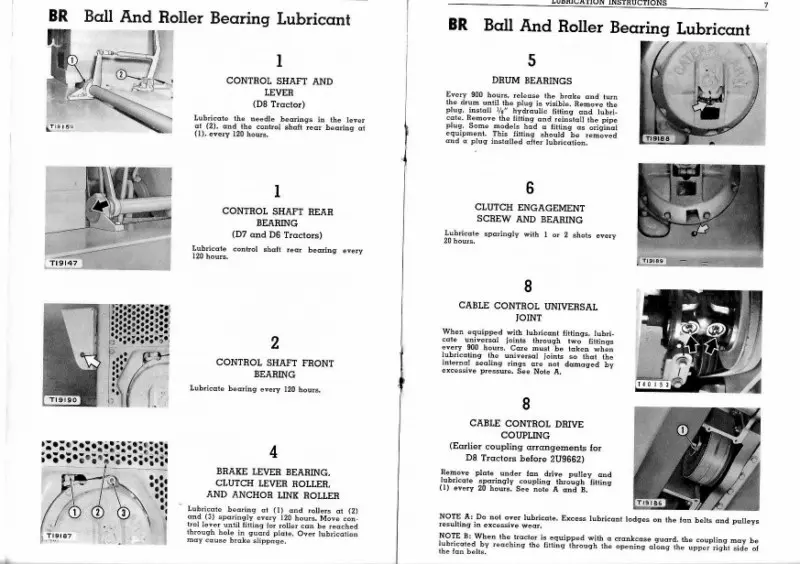

Take the fill plug out and check the oil level. Oil plug is on lower left side of the unit when standing in front of the tractor. Then lubricate every zerk and joint that you can access with a pump oiler.

If you can't get things free and working correctly you may be faced with going deeper inside the unit for repairs which most always will involve a lot of work. Don't forget to check the bearings on the control lever from the seat to the front of the tractor. There are ball bearing inside the castings on each end of the pipe.

Ours unit got a complete overhaul and it works really well.

If you have more questions, I can refer to the manual and try to help out.

[quote="Ed RD7"]Hello Clint,

I might be able to give you a few ideas. We have one on a 17a that we recently overhauled. First off, do you have the operators manual, I found one on ebay.

Take the fill plug out and check the oil level. Oil plug is on lower left side of the unit when standing in front of the tractor. Then lubricate every zerk and joint that you can access with a pump oiler.

If you can't get things free and working correctly you may be faced with going deeper inside the unit for repairs which most always will involve a lot of work. Don't forget to check the bearings on the control lever from the seat to the front of the tractor. There are ball bearing inside the castings on each end of the pipe.

Ours unit got a complete overhaul and it works really well.

If you have more questions, I can refer to the manual and try to help out.[/quote]

I have the installation manual and parts books. I checked all linkage up to the clutch lever that disappears in the unit and its all free. Oil level is good still looks like new probably because we did a complete service on it last year. I found three grease zerks two up high for rollers and one at the bottom that was hard to get to.

Where did you get yours refurbished?

Thanks Clint