Reply to anyoldiron:

............................. a better picture. The grease is coming out around the red doodle.

How do i find what kit i need, my D7 has a winch and a motor from god knows what where would i find the right #s

We could be in the same grim boat Dan!

Cheers

Hi Team,

this task should be able to be done as Flying H (welcome to the B😎 says, ie, break the track and move the idler forward after part dismantling the idler yoke and rod. This saves disturbing the recoil spring which is under 30 odd tons pressure !!!!

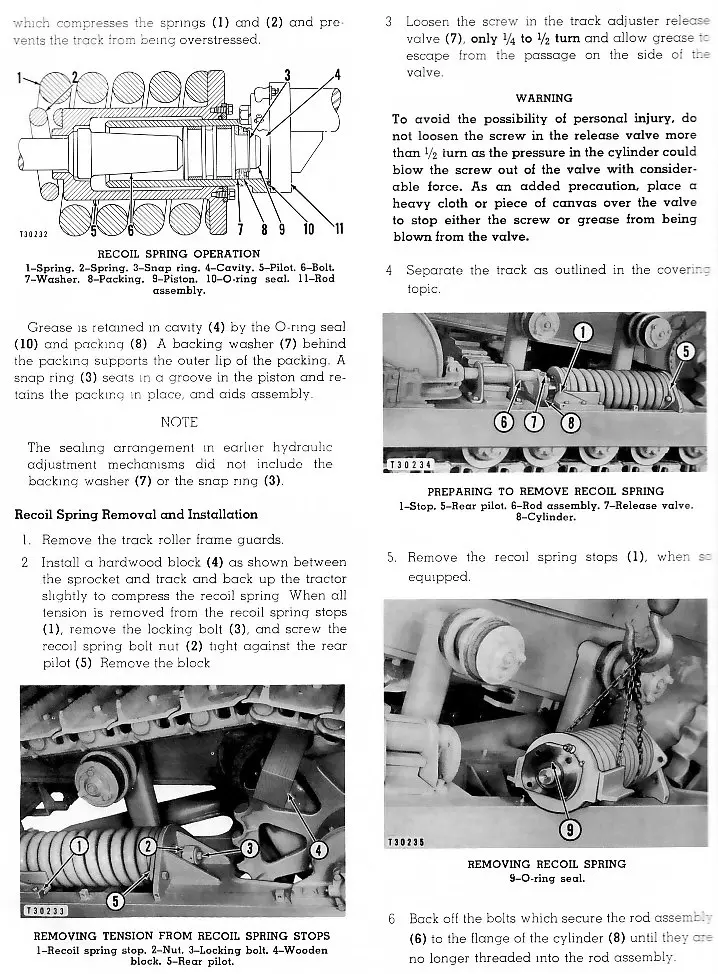

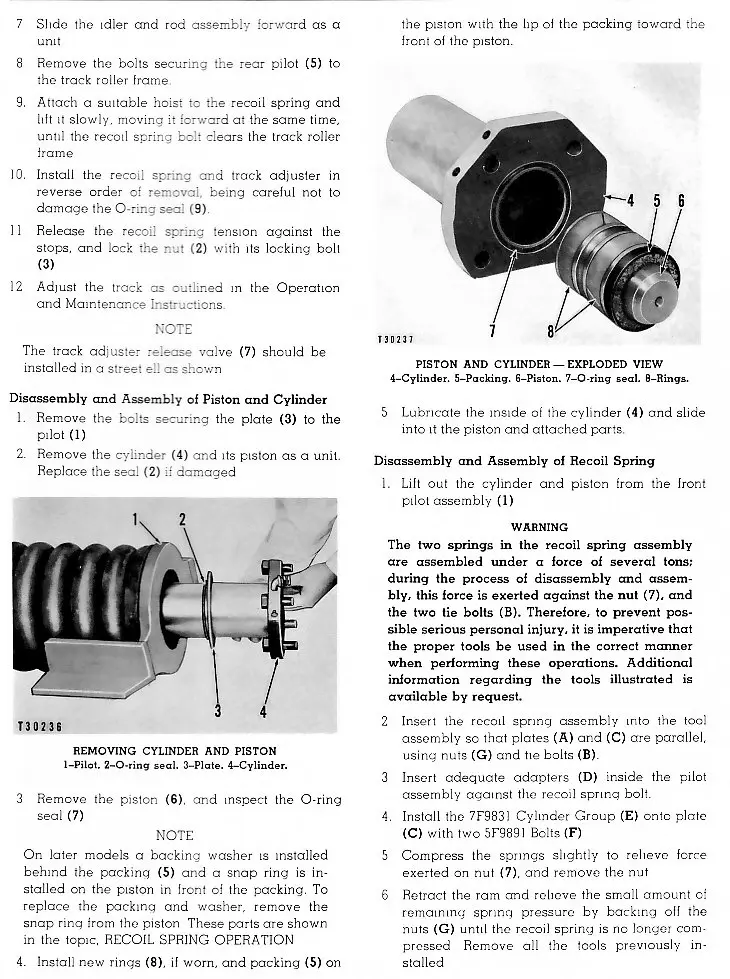

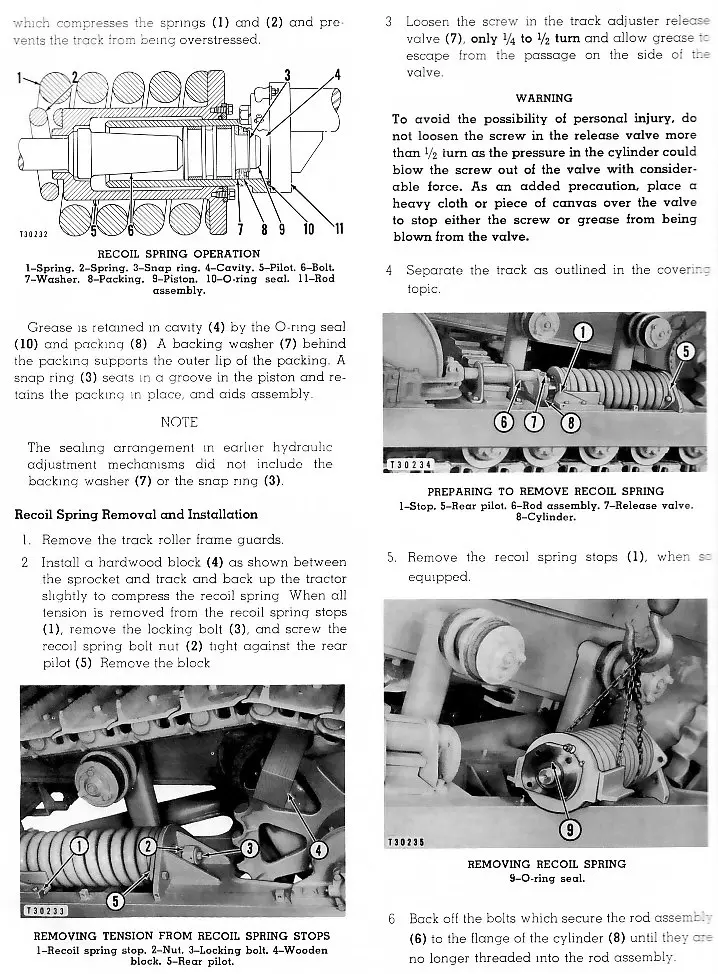

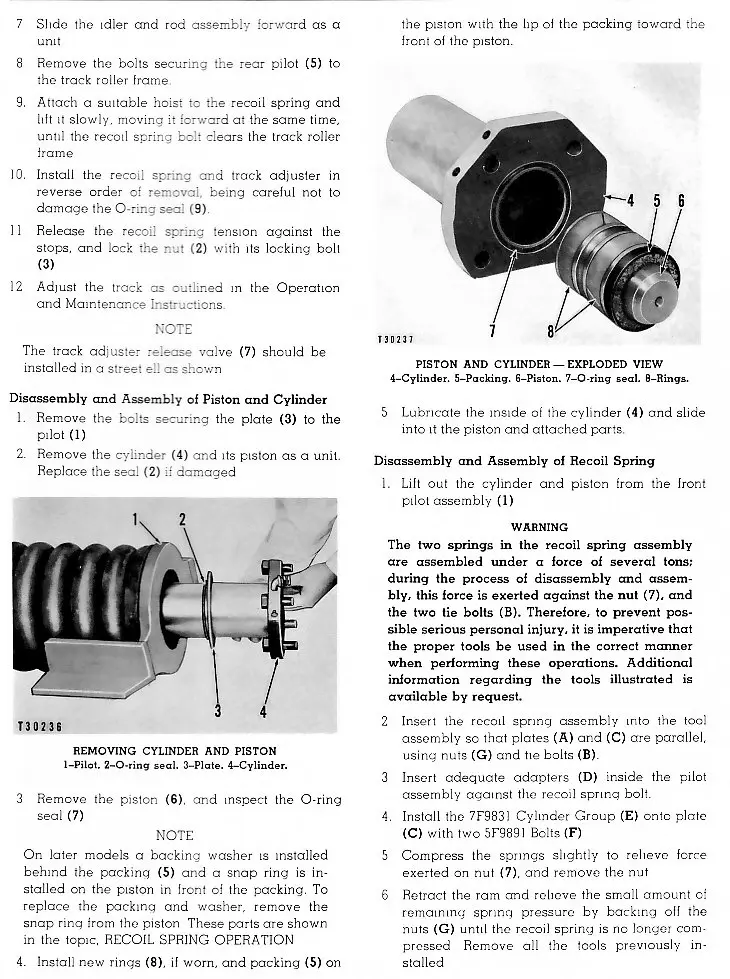

The method scanned below are the words from Yellow Father's 17A Service Manual on removal and repairing this device.

HOWEVER,

in paragraph (2) of the Recoil Spring Removal and Instalation, I suggest you do not screw the nut onto the spring bolt, as stated, because from my experience, the threads on the spring bolt will be worn from slogging about in the end cap and the nut will likely strip off the bolt, with DIRE RESULTS, when the tension is put back on it for removal of the spring unit. I suggest you use suitable spacers that will fit thru the rear spring support hole so as to keep the nut on sound threads.

Be Careful these things are lethal. The grease zerk for the adjuster is a Special high pressure one, the same applies if it is the removable zerk type. These do not have the sealing ball at the nipple outer end ( the ball can be seen on standard low pressure zerks and can shoot out and kill you) The high pressure zerks have the ball down inside the body of the zerk (ball cannot be seen in the end of the zerk)

So please check all of your hydraulic track adjuster zeks and upgrade them if needed--BE SAFE

Hope this helps.

Cheers,

Eddie B.