I have one off a D7 17A later SN so it's a WICO. It is either a 7M or 8M that I am working on. There is an X on both halves of the coupler but you need to look close to se the X on the female side. My service manual does not tell me how to time the thing but judging from what I see on the forum topics here I am going to bring number 1 cylinder to TDC on compression stroke (will look at flywheel on pony also to see it I can see the TDC mark or as mentioned above "engagement bolt" but it wont really be necessary I feel as this thing ran when it was parked 14 years ago) and be sure the magneto has just fired on #1 but not #2 (with it off and me rotating it). It should then go right on and be in correct timing. Folks have worked on this to try to start the pony for over a decade now. Based on the way the points being adjusted so they were always closed (never touching the cam) and the story on how it had to be "pre-energized" before it would have spark, I think I have a TDC exhaust stroke fire vs a TDC compression stroke fire. Will travel back to the site this Friday and hopefully make some smoke. Not sure if this method/approach gives you any insight but basically a 4 stroke motor has to fire on compression stroke, if no one has pulled the magneto gears or the camshaft drive gears apart since it last ran the it should be timed if the it up on TDC compression and it has just fired 1 on the magneto. They are saying the it is BTDC firing on the threads I read so that is why I say the magneto should have just fired #1.

Comments?

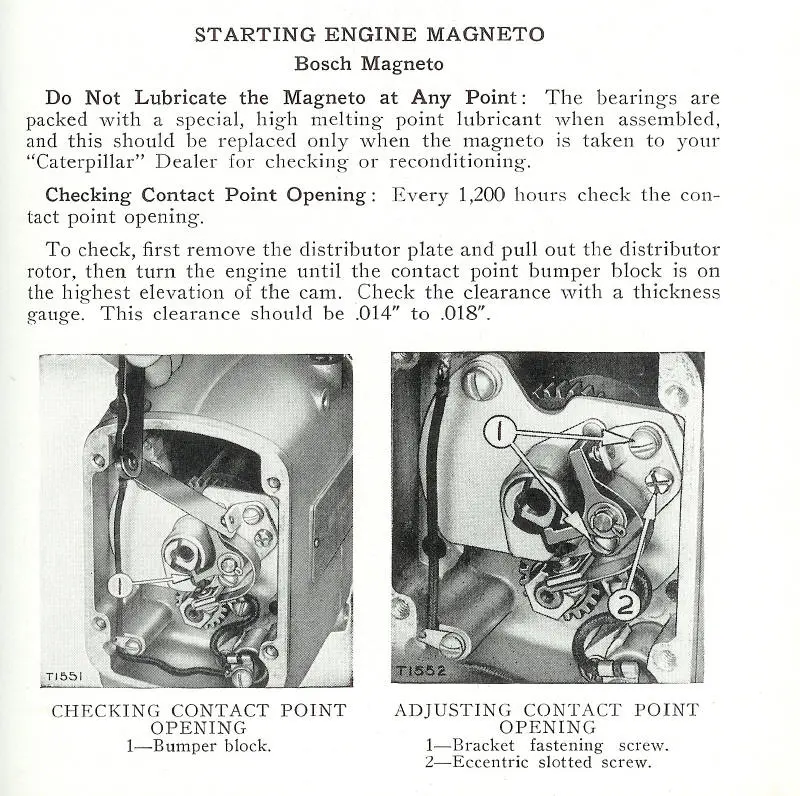

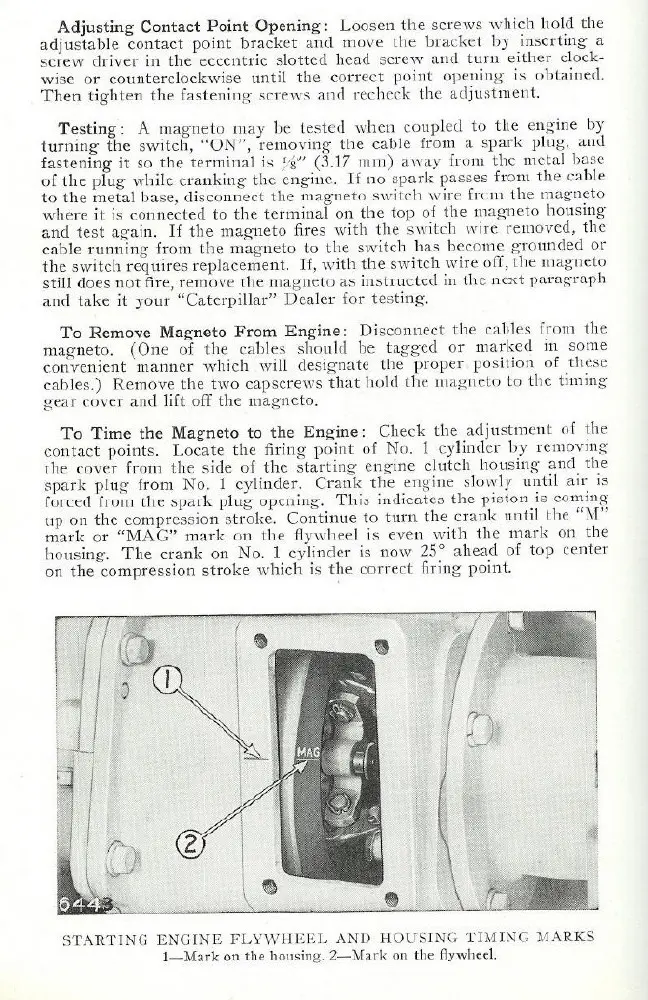

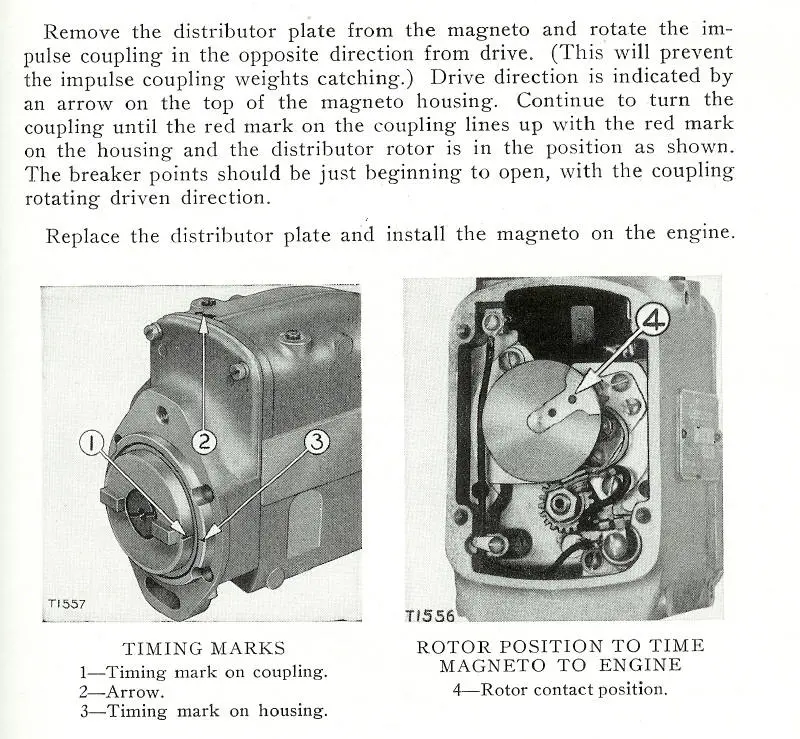

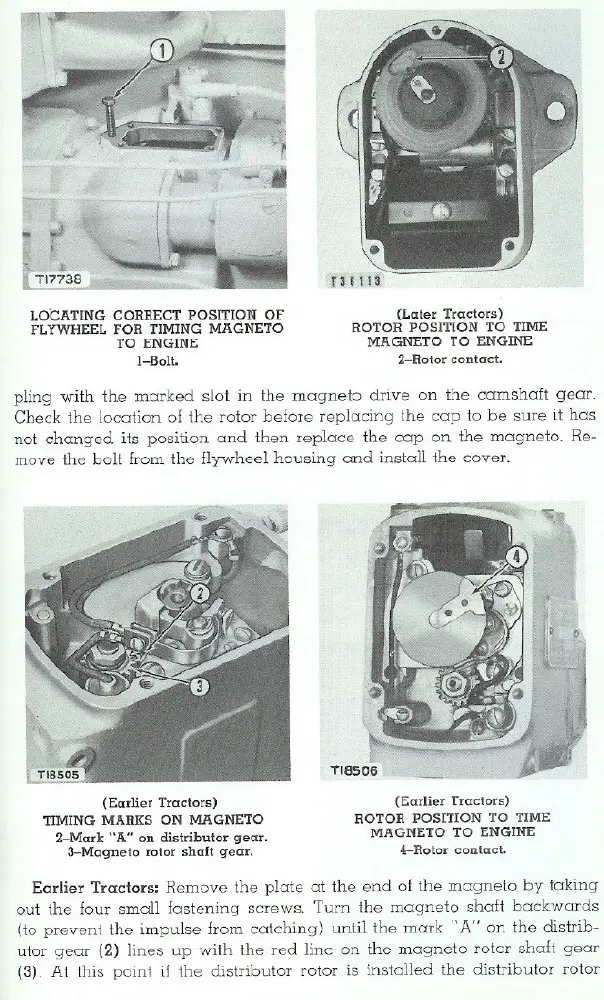

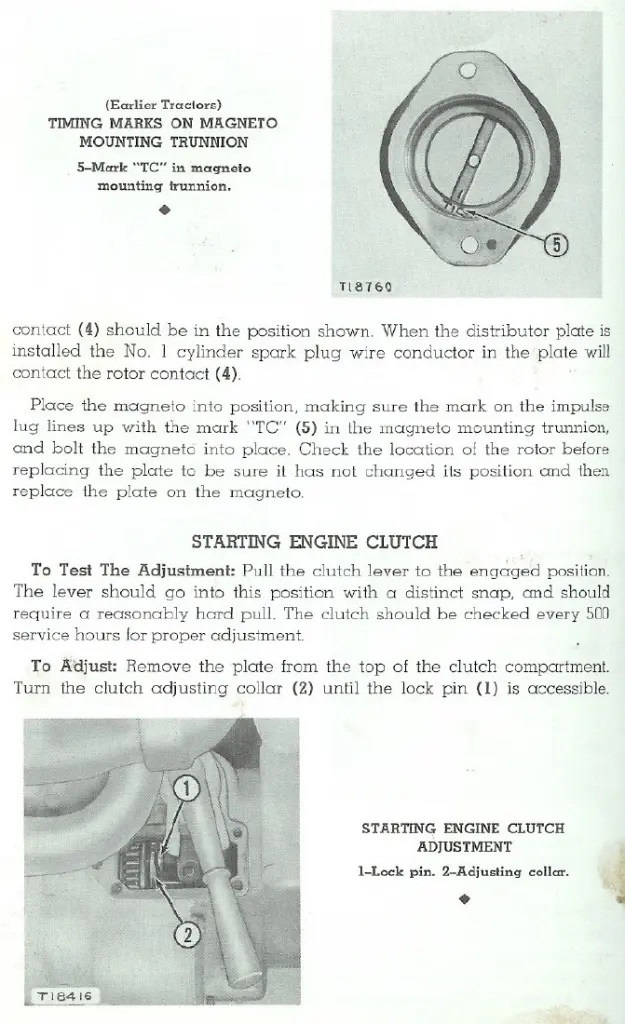

Here's how to time the Bosch Magneto, Wico should be similar:

[attachment=76550]D7 Mag Timing # 1.jpg[/attachment]

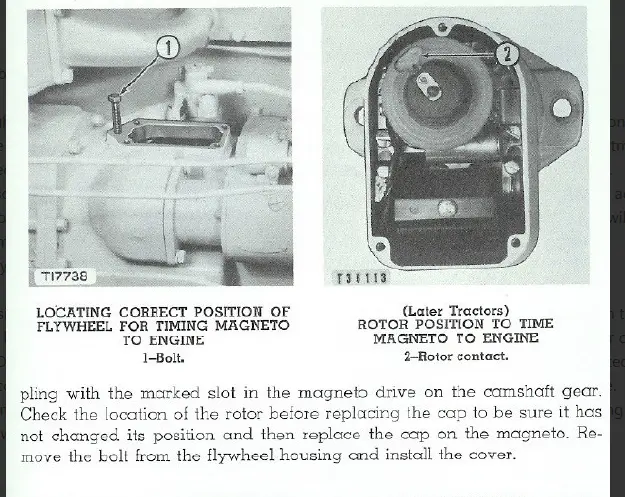

[attachment=76551]D7 Mag Timing # 2.jpg[/attachment]

[attachment=76552]D7 Mag Timing # 3.jpg[/attachment]

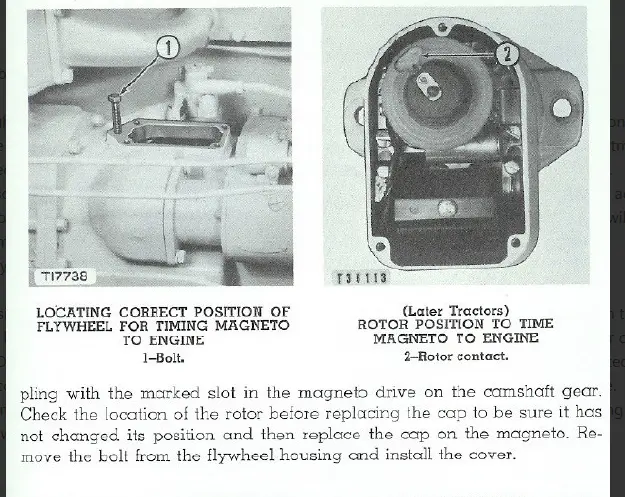

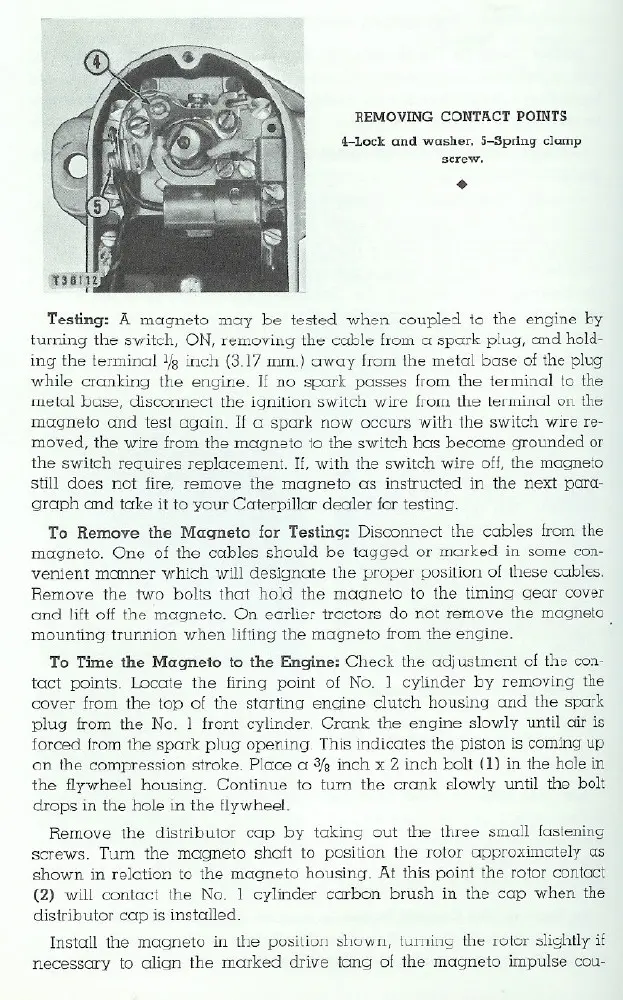

[attachment=76553]Screen Shot 05-28-24 at 11.19 AM.PNG[/attachment]Powersmoke18, what serial number us your machine? There is another forum post here that shows the 3/8 x2" bolt instructions for TDC. You have to ensure that the valve timing is coming up on #1 TDC compression (all valves closed) finger over the plug hole works to determine compression stroke as the bore is too far offset to use a dial indicator set up. Mine is a newer 17A and I don't have that sideplate depicted.

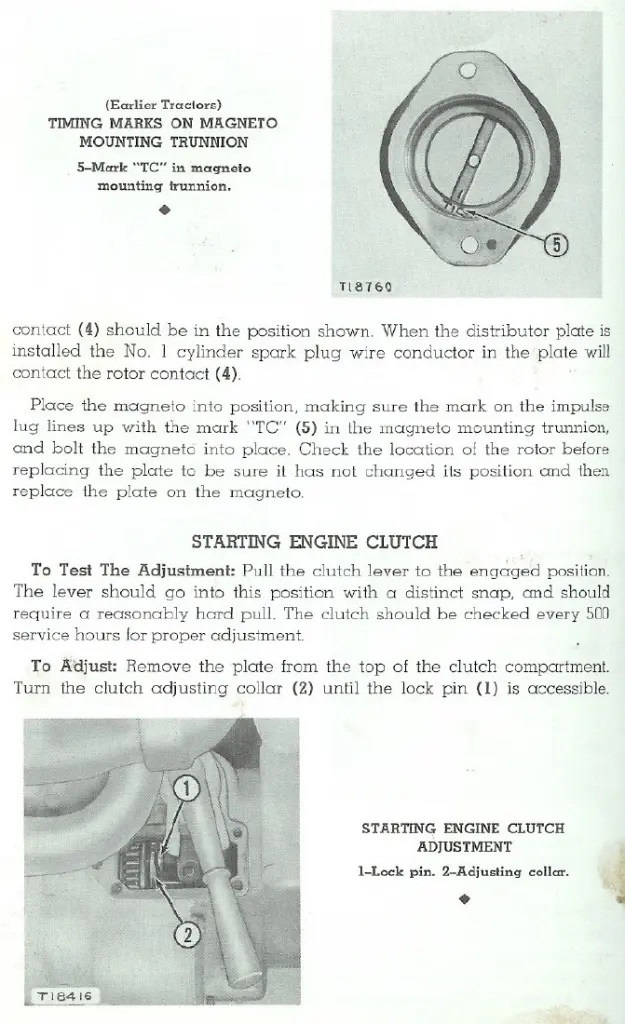

Late 17A Timing....

[attachment=76554]D7-17A Mag Timing #1.jpg[/attachment]

[attachment=76555]D7-17A Mag Timing #2.jpg[/attachment]

[attachment=76556]D7-17A Mag Timing #3.jpg[/attachment]

What I find odd is that the repair manual from Cat does not have any of this for the pony, it is only found in the Operators Manual.

What I find odd is that the repair manual from Cat does not have any of this for the pony, it is only found in the Operators Manual.