.webp)

.webp)

.webp)

Hi AOI,

maybe the impulse coupling components, with regards the lettering for Direction Of Rotation (DofR) and/or key ways needed for the specific application you need for your pony have been incorrectly orientated--I recall it as very confusing and they can be easily mixed.

It could be possible, without seeing it, that the lug sticking up that the spring assembly connects onto is 180 degrees out to the timing X on the drive tangs or a stamped chisel line on outer edge of the coupling on front of the magneto.

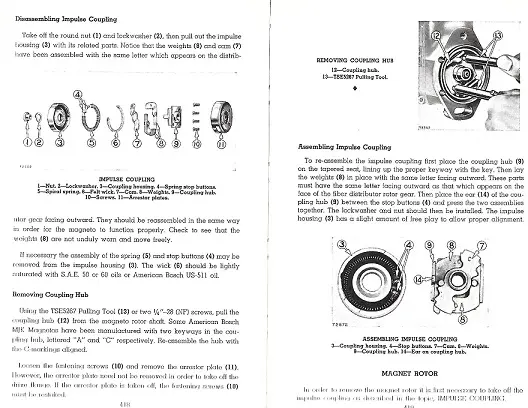

Excerpt from an Engine SRB on the AB MJK coupling that may help.

Usually were written as a general outline and so non specific to engine type--vertical or horizontal-- and D of R non-specific-- so some parts ID regarding the DofR lettering may be shown as incorrect for your actual application, as I feel they could be set for either rotation but I stand to be corrected on this--too long since I worked on one now to be sure.

Hope this helps.

Cheers,

Eddie B.

[quote="edb"]Hi AOI,

maybe the impulse coupling components, with regards the lettering for Direction Of Rotation (DofR) and/or key ways needed for the specific application you need for your pony have been incorrectly orientated--I recall it as very confusing and they can be easily mixed.

It could be possible, without seeing it, that the lug sticking up that the spring assembly connects onto is 180 degrees out to the timing X on the drive tangs or a stamped chisel line on outer edge of the coupling on front of the magneto.

Excerpt from an Engine SRB on the AB MJK coupling that may help.

Usually were written as a general outline and so non specific to engine type--vertical or horizontal-- and D of R non-specific-- so some parts ID regarding the DofR lettering may be shown as incorrect for your actual application, as I feel they could be set for either rotation but I stand to be corrected on this--too long since I worked on one now to be sure.

Hope this helps.

Cheers,

Eddie B.[/quote]

Hello Eddie.

Thanks very much for that. l dont have the in front of me but i think i know what you mean, l will pull it off tomorrow and report.

Cheers AOI

ok.

l have taken it back apart as far back as i went before. in order to rotate the tang thing 180 it now means its impossible to line up the A and strike mark on the gears.

l have set up up 180 different out of absolute %^&ing desperation as im fumbling around in the dark.

For example BOTH my weights have letters stamped on them....................

So, PLEASE PLEASE PLEASE PLEASE PLEASE PLEASE PLEASE PLEASE can some just post direct instructions from the beginning FOR THIS MAG so at least i know im going in the right direction,

Thanks, a very aggravated AOI who has shoveled 300' of 2' snow from his drive

.........................now all we have achieved is zero spark.

Hi AOI,

man these things have always been a head ache with dual usage of parts for either rotation--I recall similar issues after dismantling one and washing the pen marks I dutifully put on everything off.

The text is some 19 pages for the entire magneto section for the AB unit.

Quickly scanning thru I find the last paragraph says that :-

"a magneto housing with a part number ending with an even number is a clockwise rotation set up and those with an part number ending with an odd number is for anti-clockwise rotation"

It also says elsewhere that the direction of rotation is shown by the arrow on top of the magneto.

The Points cam gear should have either an A or a C stamped into it--as these are a direction specific item then the A or C marking should give an indication of the actual D of R for your magneto.

Am time strapped at present do help much further.

Hope this helps--if you changed anything in the impulse coupling area and the impulse is not working when on the engine it tells what needs to be changed back.

If you have simply lost spark then maybe clean and check points are set within 0.014"-0.018" I like to keep the points set to as close to 0.015"-0.016" as I can.

Cheers,

Eddie B.

Thanks for all your efforts Eddie,

lve found with this older stuff there is an ''assumption of prior knowledge'' in the literature, i struggle with it, which is a little odd considering.

The long and short of it was i lost the spark by poorly reassembling it and shorting it.

The culprit ended up being the coil, which as they tend to do tested fine and then started to fail when used............................well, it had to be everything else is new 😉 Then there was some confusion over the timing , which was fixed with a ''one last hail Mary try'' before i either set fire to it or hit it with something large.

As a ''reward'' LOL, heres a pic of what it gets to do..........and do well!

Cheers AOI

[attachment=56672]P_20200104_155444.jpg[/attachment]

I noticed in Eddie's scan that it stated to reassemble with using the C mark, not the A mark, when both are present. Could that have been / be a factor?