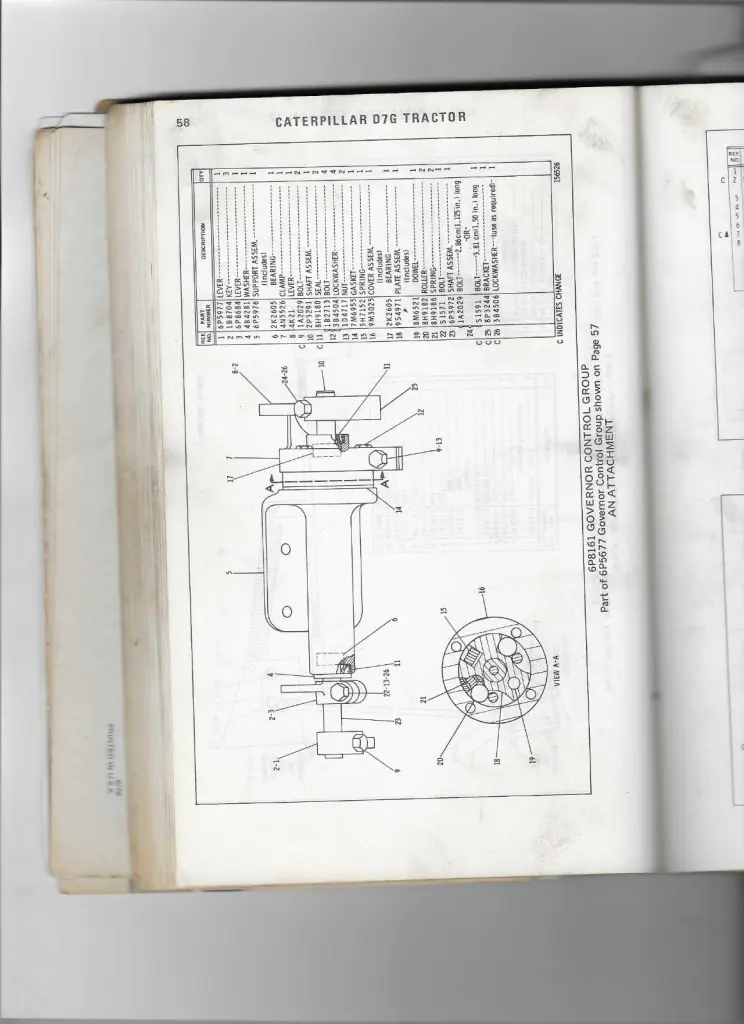

Note there are two different springs from the three. The smaller spring fits in the notch.

[attachment=70869]Throttle Control 001.jpg[/attachment]

Great, thanks! I think View A-A solves the puzzle. I did notice the smaller spring and notch but still don't see what purpose they serve. A strange device and probably never intended to be taken apart but it was frozen solid, couldn't move the governor lever at all.. cleaned it up and it's good now. just need to get it together and back on the machine. actually quite enjoyable altho it took some contorting and bruised hands to get it out of its hidey place..

Great, thanks! I think View A-A solves the puzzle. I did notice the smaller spring and notch but still don't see what purpose they serve. A strange device and probably never intended to be taken apart but it was frozen solid, couldn't move the governor lever at all.. cleaned it up and it's good now. just need to get it together and back on the machine. actually quite enjoyable altho it took some contorting and bruised hands to get it out of its hidey place..

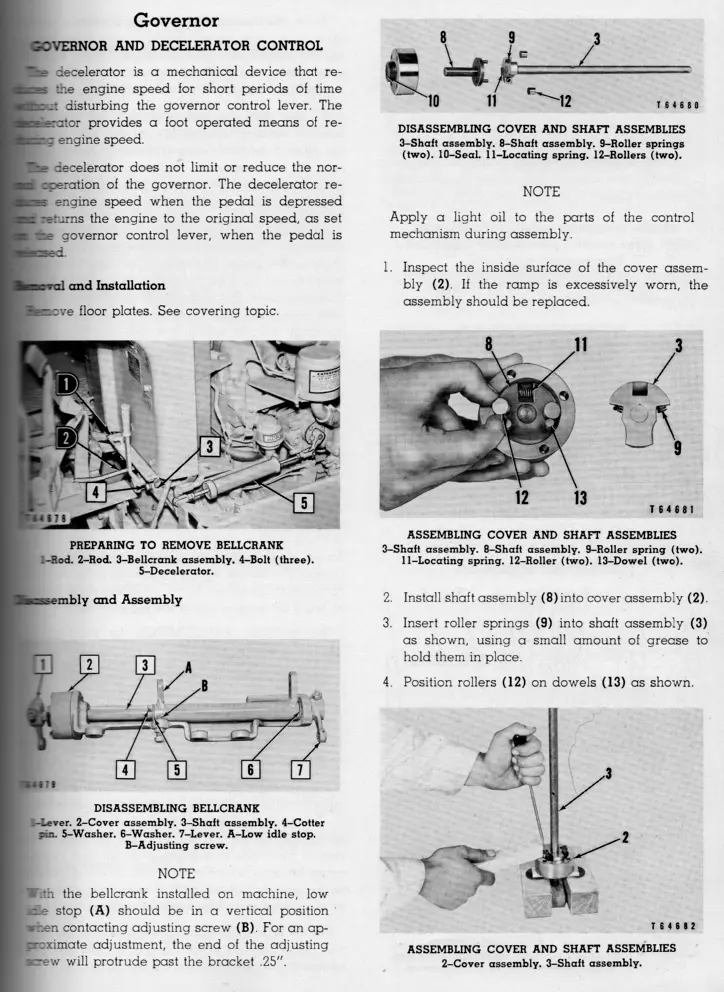

thanks Old Magnet, this info is very good. now i see the purpose of the little spring, it's just to make sure the shaft assemblies are aligned. I got the thing reassembled pretty much the way the book recommends except i used a wire to compress the roller springs. sadly, after getting it back together it's still locked up. I had thought the problem was corrosion which I cleaned. so it's something else.. it turns freely without the rollers in place. I'll have another run at it this weekend.

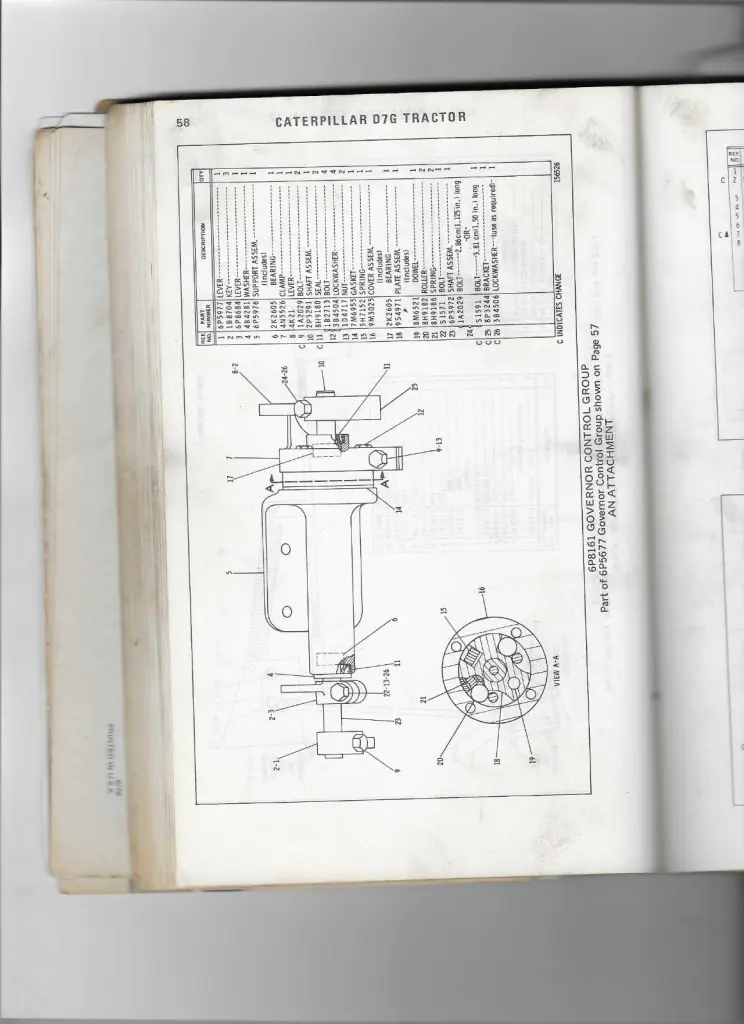

On my 76A series machine, I was having similar issues. New bushings in the bellcrank assembly and the throttle lever made the greatest improvement. Mine doesn't have a decelerator pedal so the hand lever has had all the use and it shows. I gave all the shafts and bushings and inside of the governor control a painting of anti-seize whether or not it made much difference remains to be seen. Following the picture using the wooden blocks is a near must for reassembly.

On my 76A series machine, I was having similar issues. New bushings in the bellcrank assembly and the throttle lever made the greatest improvement. Mine doesn't have a decelerator pedal so the hand lever has had all the use and it shows. I gave all the shafts and bushings and inside of the governor control a painting of anti-seize whether or not it made much difference remains to be seen. Following the picture using the wooden blocks is a near must for reassembly.

took it apart, examined all the pieces, they all look good, put it back together and it's locked again. the mystery is that one day it was working and the next day it was locked. what is the purpose of this Rube Goldberg device anyway? what would happen if I bypassed it altogether?

They are famous for function problems, more often don't hold than lock up. Conditions have to be near perfect for them to work. No worn ramps or rollers, no grease, just use light oil. Without it working there is nothing to hold throttle position.