Reply to Old Magnet:

Dang....what luck,

Other sources besides cracked head and head gasket would be leaking pre-combustion chamber seal and or pre-com chamber pin hole.

Fill it back up with water and run (if you can) to see if you are getting compression bubbles at the radiator fill. Not practical if you are dealing with a flood or suspect cylinders full of water.

Removing the head will not disturb the liners.

Hey Magnet

Yeah it got me bumbed real bad.

And probably long winded and rambling---sorry.😞

Will try not to become a pest.

It looked like I was going to be able to get back on my feet-just barely after recovering from the chemo and crap(have to do it again soon)

Well it ain't whooped me yet!

So back to the important stuff.

After the hot run(10 min later) I did check various block temps with infrared temp gage.

Highest temp reading found was 198 on the block water jacket cylinder locations.

Pulled the injectors.

#5 had drops of water on it and could see water on top of piston(?) or at least in the pre comb chamber.

#4 we could see water

Couldn't see water in the others.

(Head gasket?)

Spun engine and was amazed at the force the water shot out with!!!😮

I was such a surprised that did not get to see what cylinders made water and the amount of water discharged wet every thing to the point of not being able to tell where it actually came from.Lots of water!!!!

It did not help that after the first time we then covered engine with cardboard to keep the water off us.

The water from #5 came out with such force that it punched a hole completely through 2 layers of heavy cardboard(box flattened)!!!!!!

Any one doing this be care full! It ain't no gasoline engine!!!!!!!

Next we pulled the intake manifold cover looking for a crack from the water outlet----Found Water---looks like it came from the cylinders direction.

Hard to say.

Son is pulling water outlet(in front of manifold) so we can look for a crack from that end.

Also in the intake manifold found an O ring laying in the manifold.

O ring is approx 1/2 inch OD.????????????????

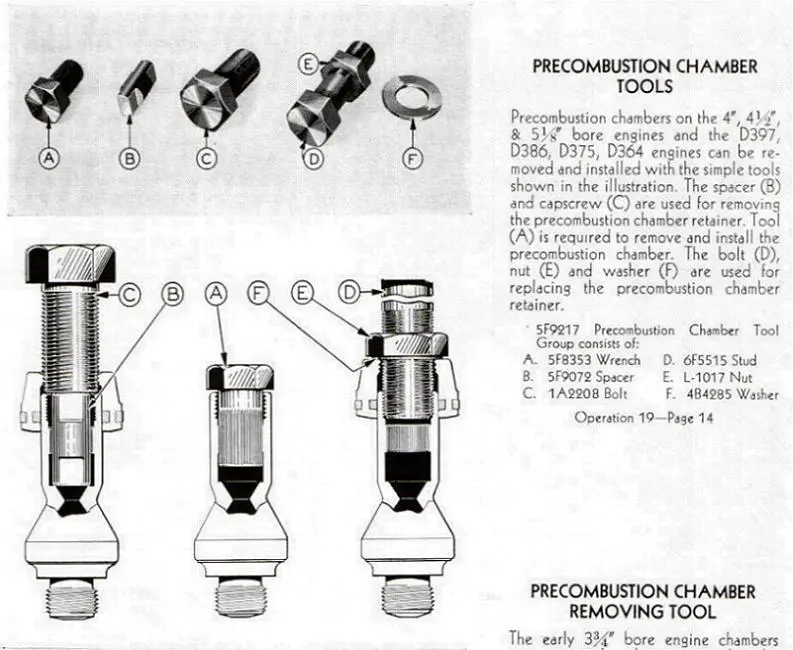

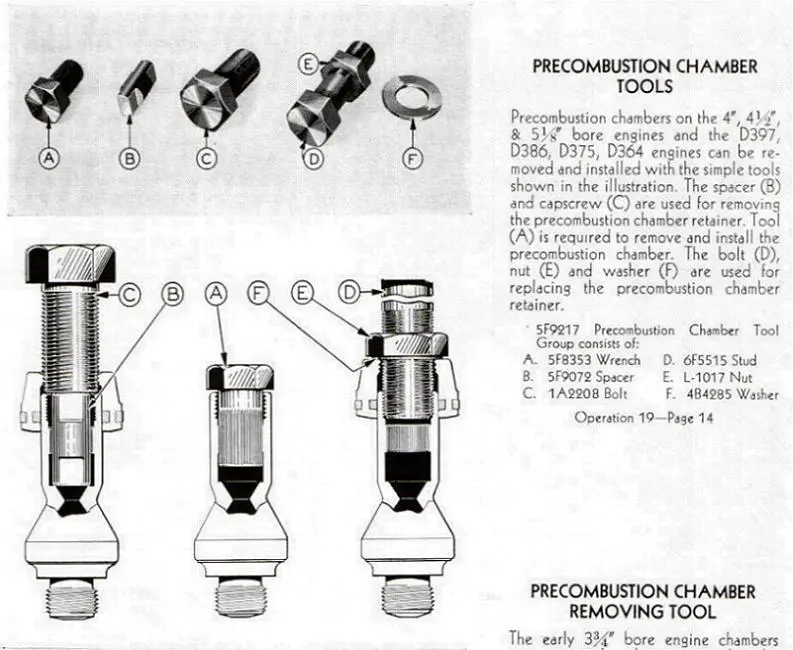

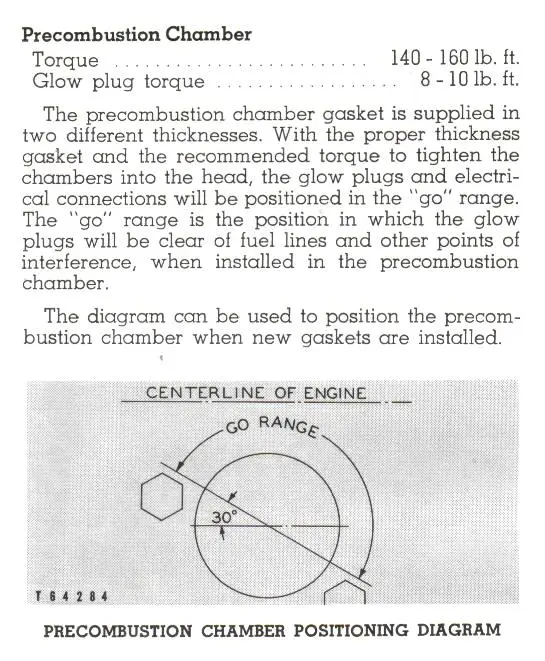

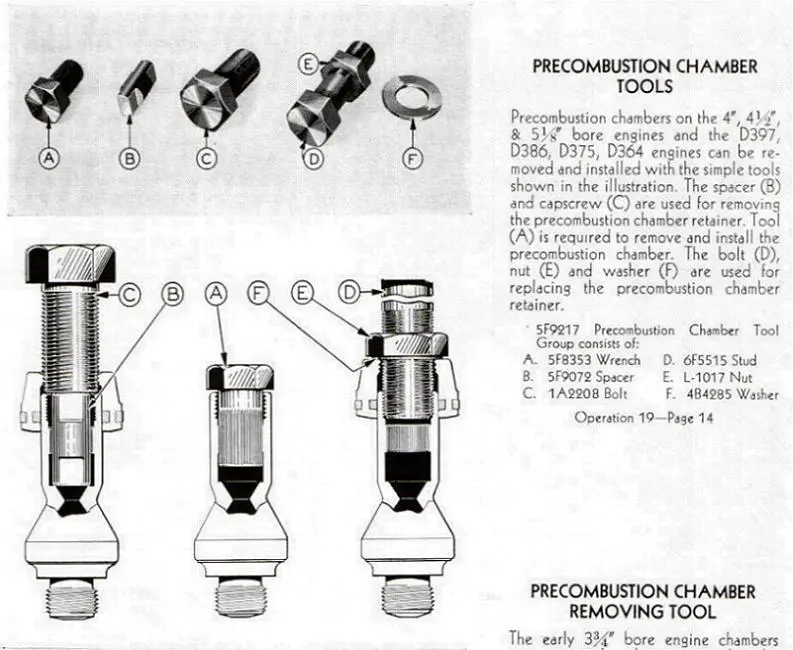

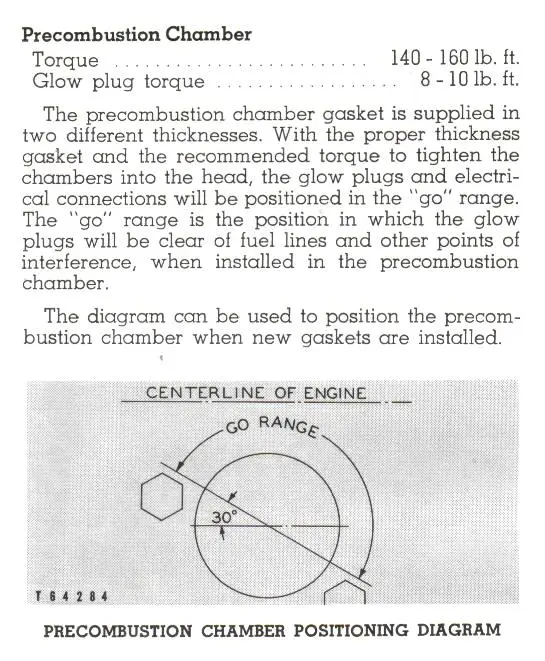

Being mainly a gas engine guy and know diesels but very rarely going into the engines I am lost on the pre combustion chamber thing.(installationaly challenged not theory)

the manuals I have are no help on this part.

There is some kind of fitting(?) with a knurled/splined(for spanner?)that the injector screwed into.

Is this the pre combustion chamber?

That would be nice! If thats where the problem is.

Need to find a wrench to fit---think I have some kind of injector wrench from the past---think it for JD though

Probably never find it anyway.

Big pair of channel locks? please don't tell anyone I said that!

My manuals are next to no use so any info that can be posted will help at this point.

D6C 76A5795(1964)

Head bolt torque

Rocker clearance

Rocker shaft bolt tq

Any thing.

The more I think about it there is not enough water in manifold to come from the front of manifold.

Hoping for an easy pre comb chamber fix.

That head looks heavy!😮

Thanks Guys

The help here is far superior to any local.😎

David