Reply to ccjersey:

Rack would be the thing that keeps the fuel rate too high. The governor should have been attached to the end of the rack, but maybe you just took off the cover and didn't remove the weights and springs etc?

The rack is also accessible at the front of the injection pump by removing a small cover abpve the accessory drive shaft that the pump bolts up to. This cover is for adjusting the rack travel. A setting gauge fits in the hole and measures the travel of the end of the rack. Forward (toward the fan/radiator) is more fuel, so you might do some gentle tapping on the end of the rack with a punch and hammer. It is possible that the rack sticking has more to do with the pump plungers being stuck up in one of the pumps.

On the older injection pumps, you could access the lifters and plunger yoke by removing a side cover on the pump housing, or even take a pump off completely by removing some bolts and the injector line. On the pump you have, it's not as easy to remove them, so I would try to gently move the rack and spray it with some kind of penetrating oil until it moves freely.

Hi Team,

I believe an 82H S/No is for a D5--same style injection pump as D6 and other engine applications of the same era.

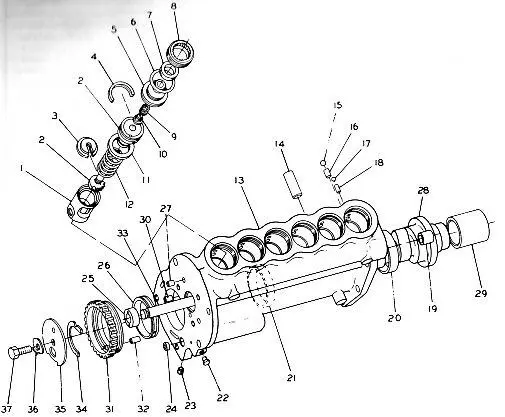

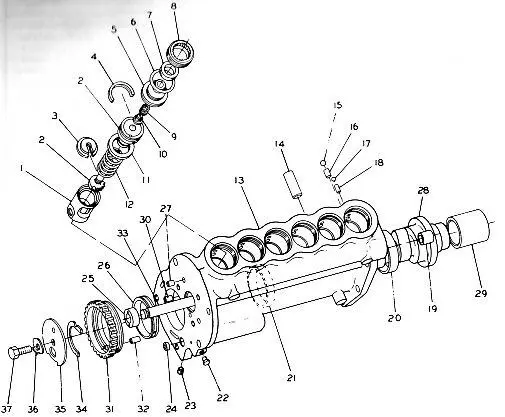

Generally known as a Compact Scroll Fuel Injection Pump in the Cat Dealer world.

Needs special tooling and expertise to remove/refit the injection pumps on these units, along with the rack being held securely in the zero position to time the plunger quadrant teeth timing marks to the rack teeth.

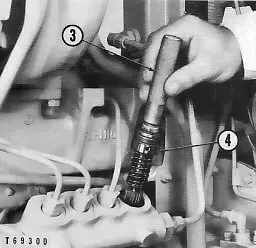

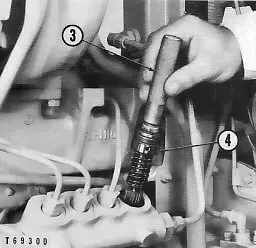

Pix attached are from different application engines but, show two types of views of the compact pump.

Third pic is of just one of the tools needed to remove/refit the plunger and barrel assemblies.

Cheers,

Eddie B.