Hi Jeff,

from memory the early engine end coupling was updated due to spline failure.

I feel sure you would be able to swap the flywheel and cover plate to get the later couping to fit.

Usual cause of failure was failed drive rubbers and/or engine to transmission mis-alignment.

There are shims under the engine mounts.

Not sure if the front engine centre mount trunion is steel or rubber bushed, If the rubber bushing collapses the engine goes out of alignment. Same applies if the machine's frame side rails/chassis have been bent or twisted out of true.

Running the unit with mis-alignment or faulty drive blocks can cause crankshaft failure.

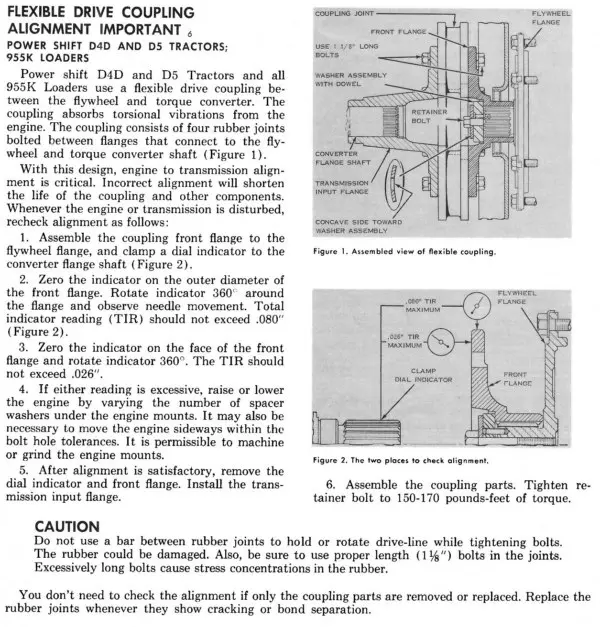

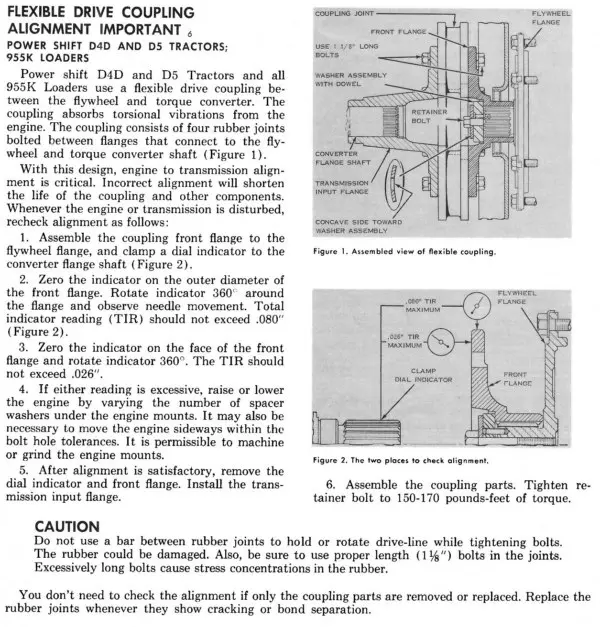

Scanned below is the procedure for checking the alignment.

Hope this helps.

Cheers,

Eddie B.

Also need to check if the holes for the engine hold down bolts are hogged out. If so dowels will need to be installed to hold the engine in the proper location after is is bolted down.

Extreme wear in the engine front support will also cause misalignment.

955K had the same splined coupling ,and spline problem .There was a change over to do away with the front splines .

Misalignment occurs because the 5/8" rear mounting bolts and lock nuts become lose due to normal engine vibration in time .The frame mounting holes are not tight around the bolts to give clearance to align the engine and coupling side to side in the frame . I have reshimed ,and realigned many 955,s 941 and 951s by using new shims ,bolts and lock nuts ..Use locktight on the bolt threads after aligning the coupling ,and torque the bolt to the cat 5/8 s bolt specs in the service manual

The doweling recommendation comes right out of the D4D service manual so apparently either the provided holes or elongated versions can not be relied upon to maintain engine location without them.

thanks for all the help. i will check out the alignment.

I have not yet pulled the sump screen out of the bottom of the transmission to inspect, i plan on doing this before i start back togther. The filter on top was clean.

Any thoughts on the overheating or do you think it is two different problems?

this is interesting--i have had my 941b (80h5029)since 1987 and have never done anything with alignment or drive rubbers--it seems to be fine when pushing hard--is there anything i should be checking??

Thanks-Dan

That s/n has the 3304 engine and upgrade to single splined coupling. So long as the rubber donuts are good and alignment is correct you shouldn't have a problem. Wouldn't hurt to check engine mount bolt torque.

Hi Jeff,

your overheating could be from the oil cooler--both the engine and transmission coolers having the packs that are part of the water flow path blocked by crud. This blockage inhibits water/coolant flow thru the entire cooling system.

Another thing on these loaders to check is the rubber baffles that seal around the radiaror core and tanks to force most of the fan forced air flow to go thru the radiator fins.

Also check the fan spider is on the correct way around.

Cheers,

Eddie B.

I know the service manual probably susjects installing dowels to eariler machines ,but what will be the time and expense ? The fenders will have to be removed on both sides ,and a magnetic portable drill press will be needed to drill the dowel holes .The coupling will have to be perfectly aligned or big problems will arise if the doewel holes are drilled with the coupling not aligned properly .

By installing the new change over coupling if it becomes out of alignment it usually only separates the rubber donut rubbers in time .Its alot easer to realign the new style coupling ,and install new rubber donuts ,and retorque the rear mounting bolts than install dowels in the mounts ,and dowels cannot be installed in the loaders because of the location of the mounts in the loader frame ,and the size of the mount is too small for a dowelhole to be drilled in it .